104 diam circular tweeter will leave 5mm recessions visible at each corner.

Use filler. Check out my edit to my previous post.

I agree.

I'll fill all of the recessed area between the circular hole and the square edge.

I have Agnews putty.

https://www.unipro.com.au/wp-content/uploads/2015/07/agnewwaterputty.pdf

I'll probably respray the baffle with matt black so it will look like the recess was never there.

Thank you for your support & patience.

I'll fill all of the recessed area between the circular hole and the square edge.

I have Agnews putty.

https://www.unipro.com.au/wp-content/uploads/2015/07/agnewwaterputty.pdf

I'll probably respray the baffle with matt black so it will look like the recess was never there.

Thank you for your support & patience.

I was very careful about the wiring done.As long as the result is airtight. It may be more likely to be airtight if you follow my suggestion in post #80.

P.S. I hope you have double/triple checked all the wiring and soldering you have done so far!

Left switch had jumper from its centre terminal to the upper terminal (where red wire will also terminate).

Right switch had jumper from from its centre terminal to the termination located between the switches.

Orange and green wires to terminal one and terminal 3 on each switch (orange to top terminal, green to lowest terminal).

Orange and green wires terminating on left side of circuit board to left switch.

Orange and green wires terminating on right side of circuit board to right switch.

Using the six holes vacated by the old caps I fitted 10mfd cap into holes at bottom of circuit board.

2 x 4.7mfd caps into remaining pairs of holes above the 10mfd cap.

Caps are all non polar.

EDIT: The square recess can be made flush with the baffle surface using filler and the Visaton surface mounted.

I'm with you on this.

Quote: I'll fill all of the recessed area between the circular hole and the square edge.

Attachments

Just an update.A modern 104 mm diameter circular faceplate tweeter could replace the uncommon (95 mm?) square faceplate tweeter provided there is enough baffle space to fit it.

The Visaton SC 10 N specifications match up pretty well with those of the KK10/8 and this possible replacement only costs £25 here in the UK:

The Mordaunt Short Pageant Series 2 owner has approved the Visaton upgrade, so I'll source a supplier and proceed.

One current issue, I can buy the Visaton's shipped from U.S. for substantially less than from the Australian dealer.

Need to weigh up the pros and cons.

Hi Galu.Spooky, Cliff, I was just thinking of you and wondering how your renovation was progressing as I opened up my laptop a few minutes ago!

Thanks for the update. I await the next with interest.

I took a punt and decided on DigiKey U.S.A. It paid off.

Parts (Visacon SC 10N's) arrived well packed, in excellent condition, and in a timely manner.

Highly recommended company.

The Visacon SC 10N tweeter assemblies fit nicely into the circular cut outs on the baffles.

Now the hurdle.

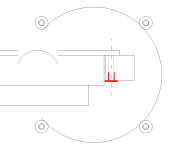

The original tweeters are on a square face plate and take advantage of diagonals to distance the fixing holes away from the circular cutouts on the baffles.

No such luck with the Visacon's.

Their fixing holes are on a circular face plate and align very very close to the edge of the holes.

A poor position to attempt to drill fixing holes.

Don't know how to resolve this situation.

16 mm mdf.

Even a modest diameter hole would be about 1 or 2 mm from the edge.

Fitting screws would breach the edge.

The skirt of the drivers is 84 mm diam.

The baffle cutouts are 86 mm diam.

The drivers face plate fixing holes are 93 mm centre to centre.

This gives 3.5 mm between the baffle cut out edge and the centre point of holes to be drilled.

If you drill 2 mm diam holes there is only 1 mm to 1.5 mm left to the edge.

The force of a screw going in would breach the edge.

Even a modest diameter hole would be about 1 or 2 mm from the edge.

Fitting screws would breach the edge.

The skirt of the drivers is 84 mm diam.

The baffle cutouts are 86 mm diam.

The drivers face plate fixing holes are 93 mm centre to centre.

This gives 3.5 mm between the baffle cut out edge and the centre point of holes to be drilled.

If you drill 2 mm diam holes there is only 1 mm to 1.5 mm left to the edge.

The force of a screw going in would breach the edge.

Might it be possible to attach the tweeter with an adhesive/sealant that remains flexible when dry? That is, without the use of screws?

This may produce a strong enough bond while permitting future removal of the tweeter should that ever prove necessary in the lifetime of the owner.

Of course, you would test that the tweeters were working correctly (lie cabinet on its back) before sealing them in place.

This is the type of product I would recommend for the task: https://www.halfords.com/motoring/p...LS*MTcxMzg5ODI4MS4xLjAuMTcxMzg5ODI4MS4wLjAuMA..

Check your auto shop for a similarly specified sealant.

You've nothing to lose by trying it as the Granville type sealant dries like rubber and can be peeled back off the tweeter.

Just a suggestion. Could save a lot of heartache and is reversible.

This may produce a strong enough bond while permitting future removal of the tweeter should that ever prove necessary in the lifetime of the owner.

Of course, you would test that the tweeters were working correctly (lie cabinet on its back) before sealing them in place.

This is the type of product I would recommend for the task: https://www.halfords.com/motoring/p...LS*MTcxMzg5ODI4MS4xLjAuMTcxMzg5ODI4MS4wLjAuMA..

Check your auto shop for a similarly specified sealant.

You've nothing to lose by trying it as the Granville type sealant dries like rubber and can be peeled back off the tweeter.

Just a suggestion. Could save a lot of heartache and is reversible.

Very eloquent solution Galu.Might it be possible to attach the tweeter with an adhesive/sealant that remains flexible when dry? That is, without the use of screws?

This may produce a strong enough bond while permitting future removal of the tweeter should that ever prove necessary in the lifetime of the owner.

Of course, you would test that the tweeters were working correctly (lie cabinet on its back) before sealing them in place.

This is the type of product I would recommend for the task: https://www.halfords.com/motoring/p...LS*MTcxMzg5ODI4MS4xLjAuMTcxMzg5ODI4MS4wLjAuMA..

Check your auto shop for a similarly specified sealant.

You've nothing to lose by trying it as the Granville type sealant dries like rubber and can be peeled back off the tweeter.

Just a suggestion. Could save a lot of heartache and is reversible.

The owner is not technical and will never pull anything apart herself.

I'll work on a sound check first before attempting to glue.

I can also fit small screws in place to finish the aesthetics once the silicone has dried.

Do you advise against other commercially available silicones' which would be used in bathroom, tiling and other building applications?

Before gluing I'll need to fill the depression in the baffle which was routed to cater for the redundant square face plates.

I have Agnews multi purpose filler which dries hard and is sand able.

I'd then respray the baffle matt black before fitting the tweeters.

This product seems similar.Check your auto shop for a similarly specified sealant.

You've nothing to lose by trying it as the Granville type sealant dries like rubber and can be peeled back off the tweeter.

Just a suggestion. Could save a lot of heartache and is reversible.

https://www.jbweld.com/product/clear-silicone

I can also fit small screws in place to finish the aesthetics once the silicone has dried.

Good idea and will give additional support.

This product seems similar.

Yes, that's the same type of sealant as the Granville.

- Home

- Loudspeakers

- Multi-Way

- Assistance with Mordaunt Short Pageant Series 2