I have been trying to very slowly gather parts to have an outdoor cinema for me to share with others. I originally wanted to build a TH221 clone. That would offer me everything I would want in one easy to move cabinet. LOL easy to move.

So I started simulating other designs and realized that the Othorn might be a better option for my wants. It was tuned higher but did have quite a bit more spl because of that. I think the Othorn is about 27hz tuned.

So thats what I was aiming at with my design. At home at lesser voltage I wont have a Hpass at all. And at home in my backyard the low end will be noticeable. Now when out with a pair of these FLH's and Hpasses in place I might not notice the 20hz at all because of the rest of the BW being so much louder.

SO I wanted to have high 25hz SPL when Hpassed outdoors. And I feel both the Othorn and my design do this just fine.

113db's at 20hz and 125dbs at 25hz seems to me be reasonable when Hpasses are put in place.

So I started simulating other designs and realized that the Othorn might be a better option for my wants. It was tuned higher but did have quite a bit more spl because of that. I think the Othorn is about 27hz tuned.

So thats what I was aiming at with my design. At home at lesser voltage I wont have a Hpass at all. And at home in my backyard the low end will be noticeable. Now when out with a pair of these FLH's and Hpasses in place I might not notice the 20hz at all because of the rest of the BW being so much louder.

SO I wanted to have high 25hz SPL when Hpassed outdoors. And I feel both the Othorn and my design do this just fine.

113db's at 20hz and 125dbs at 25hz seems to me be reasonable when Hpasses are put in place.

Last edited:

Hi Josh,

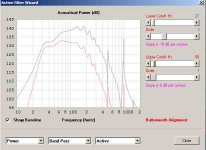

Capturing the Maximum SPL chart and then comparing the result against the Acoustical Power chart calculated at different values of Eg, should give you what you want, without the need for another chart in Hornresp.

To illustrate, the attached screenprint shows the default record Maximum SPL response (grey trace) compared against the Acoustical Power response calculated at Eg = 30 volts (black trace). The Acoustical Power response exceeds the specified displacement / power limits at those frequencies where the grey trace is lower than the black trace. As you can see, for a constant input of 30 volts, Xmax is exceeded up to about 60Hz, and Pmax is exceeded (just slightly) from about 600Hz to 1000Hz.

The Acoustical Power response can be calculated for any given value of Eg, and the captured Maximum SPL response quickly superimposed by pressing F4.

Kind regards,

David

Thanks for the reply David. You are correct of course and that is quite useful but I find myself doing a lot of comparison between different systems and there is no way to get all of this data for 2 designs onto one graph for quick assessment. You have to load the voltage sensitivity for one design, capture and compare, then switch to the max spl graph capture and compare.

I'm just curious of the reason for having the max spl graph be linked to constant input power and excursion, rather than constant voltage and excursion which is how modern amplifiers and speakers behave for the most part?

Hi chrapladm,

Here is another fold for the 21SW152 FLH.

I started w/ a simulation that looked OK. Then I picked the side view size by cutting a 5'x5' sheet of plywood in half (on paper). The internal width I set @ a 4'x8'sheet cut in half lengthwise. I stuffed the driver into a corner @ 45°. As you can see this is all very scientific. I had calculated the "optimum" throat area to be ~360cm^2, so I didn't change the S2=389 from the simulation (still looks tight to me, I hope somebody w/ experience in building FLH subwoofers chimes in on this).

I had calculated the "optimum" throat area to be ~360cm^2, so I didn't change the S2=389 from the simulation (still looks tight to me, I hope somebody w/ experience in building FLH subwoofers chimes in on this).

The next step was to export the horn flare for the constant internal width of 60.80cm from the Schematic window in Hornresp, and to enter this into the AutoCAD drawing. The fold flowed down and around from S2 checking the horn length to the corners, and picking the horn height from the exported flare (that way we'll get Par individual sections adding up to an Exp flare).

As you can see the final horn is still a little short, and S5 is larger than simulated. The next try might be adding 6" to the depth (29.938 + 6). That would make the horn path ~45cm longer (longer=lower), that would also be the time to optimize the simulation again.

I'll attach the original simulation (#4), the Schematic Export file , the simulation derived from the drawing, a quick SPL simulation and the drawing.

Hope this will help getting you started. Like so many other things: folding is 5% inspirations and 95% perspiration.

Regards,

Here is another fold for the 21SW152 FLH.

I started w/ a simulation that looked OK. Then I picked the side view size by cutting a 5'x5' sheet of plywood in half (on paper). The internal width I set @ a 4'x8'sheet cut in half lengthwise. I stuffed the driver into a corner @ 45°. As you can see this is all very scientific.

The next step was to export the horn flare for the constant internal width of 60.80cm from the Schematic window in Hornresp, and to enter this into the AutoCAD drawing. The fold flowed down and around from S2 checking the horn length to the corners, and picking the horn height from the exported flare (that way we'll get Par individual sections adding up to an Exp flare).

As you can see the final horn is still a little short, and S5 is larger than simulated. The next try might be adding 6" to the depth (29.938 + 6). That would make the horn path ~45cm longer (longer=lower), that would also be the time to optimize the simulation again.

I'll attach the original simulation (#4), the Schematic Export file , the simulation derived from the drawing, a quick SPL simulation and the drawing.

Hope this will help getting you started. Like so many other things: folding is 5% inspirations and 95% perspiration.

Regards,

Attachments

You know you could make a lot of money if you made one that was a bit more flexible and could handle other fold styles and include chambers too, right? People don't seem to like folding.

LOL, that's way past my Excel-fu level

I'm just curious of the reason for having the max spl graph be linked to constant input power and excursion

Hi Josh,

The purpose of the Maximum SPL chart is to show the maximum output that can be achieved without exceeding either the specified Pmax or Xmax limit of the driver. In effect, it shows the "performance envelope" of the driver in a given system.

Kind regards,

David

Last edited:

A bit confused on what your external dimensions were? 48" x 30" x 24"?Hi chrapladm,

Here is another fold for the 21SW152 FLH.

I started w/ a simulation that looked OK. Then I picked the side view size by cutting a 5'x5' sheet of plywood in half (on paper). The internal width I set @ a 4'x8'sheet cut in half lengthwise. I stuffed the driver into a corner @ 45°. As you can see this is all very scientific.I had calculated the "optimum" throat area to be ~360cm^2, so I didn't change the S2=389 from the simulation (still looks tight to me, I hope somebody w/ experience in building FLH subwoofers chimes in on this).

The next step was to export the horn flare for the constant internal width of 60.80cm from the Schematic window in Hornresp, and to enter this into the AutoCAD drawing. The fold flowed down and around from S2 checking the horn length to the corners, and picking the horn height from the exported flare (that way we'll get Par individual sections adding up to an Exp flare).

As you can see the final horn is still a little short, and S5 is larger than simulated. The next try might be adding 6" to the depth (29.938 + 6). That would make the horn path ~45cm longer (longer=lower), that would also be the time to optimize the simulation again.

I'll attach the original simulation (#4), the Schematic Export file , the simulation derived from the drawing, a quick SPL simulation and the drawing.

Hope this will help getting you started. Like so many other things: folding is 5% inspirations and 95% perspiration.

Regards,

I was thinking 48 x 48 but then you said depth of 30" + 6 more. I still need to check out your attachments and go from there.

For me I am going to try and stick with a vertical mounted driver also. Not sure how yours was going to be mounted at a 45 degree angle as you mentioned.

Also S2 at 389 is optimum?

Why is that?

That would be a 4.3 compression. Is this optimal for the enclosure you mean and not optimum for the driver?

Just a bit confused. BUT as usual thanks a bunch for having a look and suggesting some more great ideas. I look forward to your ideas about how to get more length added on also. I have 18mm at 29hz with your Hpass and 107v.

BUT saying that your simulation is not very far off of mine for low end. 45cm addition will probably make it the same for low end or better. BUT after saying this did you say that your simulation did not fit into your fold?

Last edited:

Posts #203 and 206

Hi chrapladm,

To answer some of your questions:

I'm assuming that you have not looked at the drawing yet, but as I said in #203: "...I picked the side view size by cutting a 5'x5' sheet of plywood in half...The internal width I set @ a 4'x8'sheet cut in half lengthwise...". That gives a H5'x D2.5' x Wint2' box.

The throat calculation is from the formula: St=(2*pi*fs*Qts*Vas)/c (sources oppenberg, Melhuish, Edgar (Edgar uses Qes) and others); where St=horn throat, c=speed of sound. St=350.69cm^2 (at least that's what I get, often you'll see Ah used instead of St). The final value in the drawing of the fold was from using the sliders in Hornresp. Also, see link in Post #163. If that is too small or not I cannot evaluate, Josh Ricci should be able to help with all of his practical experience with this driver.

oppenberg, Melhuish, Edgar (Edgar uses Qes) and others); where St=horn throat, c=speed of sound. St=350.69cm^2 (at least that's what I get, often you'll see Ah used instead of St). The final value in the drawing of the fold was from using the sliders in Hornresp. Also, see link in Post #163. If that is too small or not I cannot evaluate, Josh Ricci should be able to help with all of his practical experience with this driver.

Mainly, I thought this was a good example to show you how to go from an Exp simulation in Hornresp to multiple Par section in the fold in a drawing. When converting from a simulation to a drawing (or to wood, in the end the wood is always right!) you'll often find that the final in the drawing will not quite meet up w/ the simulation, then you can adjust either your drawing, e.g.: by making the overall size larger or smaller, or adjust the simulation. Usually I end up adjusting both. If I were to take another swing at this one I would start w/ a side view of 5' x 3' (or: H60" x D36"), and an internal width of 2' (Wint24"). The temptation is to squeeze the size as much as possible, but that pushes the compromise in the wrong direction; then it would be better to go w/ a TH, a TQWT or even a BR.

As to the 45° mounting angle, it looked like an easy way to get the approximate back chamber volume, and sufficient access panels to hoist that monster into the box. By the way, my calculations for the driver give me a driver displacement of ~15.36litres, Hornresp shows net volumes.

Regards,

Hi chrapladm,

To answer some of your questions:

I'm assuming that you have not looked at the drawing yet, but as I said in #203: "...I picked the side view size by cutting a 5'x5' sheet of plywood in half...The internal width I set @ a 4'x8'sheet cut in half lengthwise...". That gives a H5'x D2.5' x Wint2' box.

The throat calculation is from the formula: St=(2*pi*fs*Qts*Vas)/c (sources

Mainly, I thought this was a good example to show you how to go from an Exp simulation in Hornresp to multiple Par section in the fold in a drawing. When converting from a simulation to a drawing (or to wood, in the end the wood is always right!) you'll often find that the final in the drawing will not quite meet up w/ the simulation, then you can adjust either your drawing, e.g.: by making the overall size larger or smaller, or adjust the simulation. Usually I end up adjusting both. If I were to take another swing at this one I would start w/ a side view of 5' x 3' (or: H60" x D36"), and an internal width of 2' (Wint24"). The temptation is to squeeze the size as much as possible, but that pushes the compromise in the wrong direction; then it would be better to go w/ a TH, a TQWT or even a BR.

As to the 45° mounting angle, it looked like an easy way to get the approximate back chamber volume, and sufficient access panels to hoist that monster into the box. By the way, my calculations for the driver give me a driver displacement of ~15.36litres, Hornresp shows net volumes.

Regards,

Huge thanks for this TB46. I calculated a roughly 600liter net cabinet size when using 60 x 30" x 24". 60 x 36 x 24" maybe nets to 720l. These are not exact numbers just guestimates. The net values are for a simple square cabinet using 3/4" wood(19mm). Ans then subtracting a bit more for internal panels. Just a guess.

BUT all this changes on which plywood is available to me. I will be trying to use the cheapest I can find for the first build. That will most likely be 19mm. BUT in the end when I have something that I am happy with I will use 18mm.

18mm Marine ply cost about 120 a sheet. 1220 x 2440mm

19mm Econo ply cost about 80 a sheet. 1200 x 2400mm

12mm nonstructural ply cost 34 a sheet. 1220 x 2440

So most of my builds I use Marine ply if they are finalized like the Othorn. Fot first attempts I us the cheaper ply. When trying to use any other type of BB ply or A/A grade regular ply it is 150 dollars or even more for BB. SO I use marine.

And your compression is the main concern. I think it would probably be fine but not sure. I know Ricci used 400 on S2 in the Othorn and people always commented on that. Saying that it was high but the 21" is a special driver so it was fine. Not sure the 21IPAL has a stronger cone or not but I think, think Ricci is pushing that driver harder in compression that the Othorn in another design of his own.

And regarding your mention of 4 x8 cut in half I was thinking 2 x 4. So thats why I was confused. And yes it is all clear about what your doing after seeing your drawing. And amazingly enough to me after looking at the dual 18" BC218 the 21" FLH here is about equal with the DSL. Meaning it is more than half the size but it does use a 21" not a 18". So we seem to be on the right track for size. Not that that matters at all.

Either way this will be one big horn.

BUT all this changes on which plywood is available to me. I will be trying to use the cheapest I can find for the first build. That will most likely be 19mm. BUT in the end when I have something that I am happy with I will use 18mm.

18mm Marine ply cost about 120 a sheet. 1220 x 2440mm

19mm Econo ply cost about 80 a sheet. 1200 x 2400mm

12mm nonstructural ply cost 34 a sheet. 1220 x 2440

So most of my builds I use Marine ply if they are finalized like the Othorn. Fot first attempts I us the cheaper ply. When trying to use any other type of BB ply or A/A grade regular ply it is 150 dollars or even more for BB. SO I use marine.

And your compression is the main concern. I think it would probably be fine but not sure. I know Ricci used 400 on S2 in the Othorn and people always commented on that. Saying that it was high but the 21" is a special driver so it was fine. Not sure the 21IPAL has a stronger cone or not but I think, think Ricci is pushing that driver harder in compression that the Othorn in another design of his own.

And regarding your mention of 4 x8 cut in half I was thinking 2 x 4. So thats why I was confused. And yes it is all clear about what your doing after seeing your drawing. And amazingly enough to me after looking at the dual 18" BC218 the 21" FLH here is about equal with the DSL. Meaning it is more than half the size but it does use a 21" not a 18". So we seem to be on the right track for size. Not that that matters at all.

Either way this will be one big horn.

Last edited:

18mm Marine ply cost about 120 a sheet. 1220 x 2440mm

19mm Econo ply cost about 80 a sheet. 1200 x 2400mm

12mm nonstructural ply cost 34 a sheet. 1220 x 2440

18 mm OSB costs $18 a sheet here.

It's good for throw away test boxes.

So we seem to be on the right track for size. Not that that matters at all.

Either way this will be one big horn.

If you want to fairly compare the alignments, comparing a 400 liter tapped horn to a 700 liter flh isn't really fair. No more fair than using different drivers in different horns and trying to compare.

As I mentioned way back, size is a choice. Something as small as 264 liters can work. It clearly won't be as efficient as your newest designs which are almost 3x larger and you probably know that, but sometimes when the sim keeps looking better and better when the horn is bigger and bigger things get carried away and you lose focus of the original goal. Remember telling me you wanted it between 500 and 600 liters?

You can do whatever you want of course and bigger IS better, but I'm just reminding you that size IS a choice and you are way outside of your original goal at this point.

Thanks for the reminder. I am not 19 anymore and fully understand how big these cabinets are getting. I also realize that this is a 21" driver and I dont want to cram it in a sealed box of about 2cuft. Large enough that were near rated RMS to hit Xmax would be good but lets not go higher than were already are at 680l.18 mm OSB costs $18 a sheet here.

It's good for throw away test boxes.

If you want to fairly compare the alignments, comparing a 400 liter tapped horn to a 700 liter flh isn't really fair. No more fair than using different drivers in different horns and trying to compare.

As I mentioned way back, size is a choice. Something as small as 264 liters can work. It clearly won't be as efficient as your newest designs which are almost 3x larger and you probably know that, but sometimes when the sim keeps looking better and better when the horn is bigger and bigger things get carried away and you lose focus of the original goal. Remember telling me you wanted it between 500 and 600 liters?

You can do whatever you want of course and bigger IS better, but I'm just reminding you that size IS a choice and you are way outside of your original goal at this point.

I dont like in Canada but thanks for the OSB price.

And like I said I thought about building a FLH with the same size as the Othorn. BUT then I dont tend to throw away any designs I have built. I have quite a few empty horns in my shed. So thats where size started to get more relaxed. Sure Othorn size would be nice for the comparison but as we went through you were forced to use a lot more power. So this became more of a good design using a 21" in a FLH. Not really going to compare it to the Othorn for sheer "this is better because."

I will have eventually four cabinets with a 21SW152 in each. For small pack space Othorn will do. For more space the FLH will do.

So thats how I am seeing the main differences between the two cabinets. Both do the same BW well and will have plenty of SPL. YES it is larger but if you are tight on space build the Othorn. I have the liberty that space is not a big deal for me. So lets bring on the FLH.

Ok, if a fair comparison is not the #1 goal then bigger is always better as long as you can move it if you have to.

I thought a fair comparison was the main goal and small size a close second based on your comments, that's why I started off showing an extremely small flh. This whole thing started because you were talking about buying an 18 inch driver because you didn't think a horn for a 21 would be a reasonable size.

Anyway, no matter where you live, if OSB is available it should always be cheaper than any decent void free plywood by a factor of at least 2 and probably quite a bit more than that.

I thought a fair comparison was the main goal and small size a close second based on your comments, that's why I started off showing an extremely small flh. This whole thing started because you were talking about buying an 18 inch driver because you didn't think a horn for a 21 would be a reasonable size.

Anyway, no matter where you live, if OSB is available it should always be cheaper than any decent void free plywood by a factor of at least 2 and probably quite a bit more than that.

Ya I will have a look and see if I can bind OSB.If not form ply is cheaper also but not sure by how much.Ok, if a fair comparison is not the #1 goal then bigger is always better as long as you can move it if you have to.

I thought a fair comparison was the main goal and small size a close second based on your comments, that's why I started off showing an extremely small flh. This whole thing started because you were talking about buying an 18 inch driver because you didn't think a horn for a 21 would be a reasonable size.

Anyway, no matter where you live, if OSB is available it should always be cheaper than any decent void free plywood by a factor of at least 2 and probably quite a bit more than that.

And yes I know this started off as a friendly comparison. BUT I will just use what I have and go from there. Other wise it was going to cost me another 450 dollars to do the FLH with an 18. And if anything I would love to build a BC218. So moving on we are going to be just happy and fine with the FLH 21.

I dont think I will be able to make a portable concrete wall.

Last edited:

Is volume the only way to get better performing 25-45hz performance in this FLH?

I have looked at all the versions so far and with Hpasses in place to keep everything from going over 14mm they are all pretty close to each other but the larger versions have a much better 25-45. They are around 130db at 30hz with about 122 at 25hz. But as soon as we get smaller some simulations do 122db at 25hz but never get to 130db until 45hz. Or the simulations do much less at 25hz but 130db at 30hz.

The closest to do 122 @ 25 and 130 @30hz was TB's first sim using ND and it was about 630 liters.

And yes I know I can push the 21" past 14mm it was just a number I stuck with in all the simulations for comparing.

I have looked at all the versions so far and with Hpasses in place to keep everything from going over 14mm they are all pretty close to each other but the larger versions have a much better 25-45. They are around 130db at 30hz with about 122 at 25hz. But as soon as we get smaller some simulations do 122db at 25hz but never get to 130db until 45hz. Or the simulations do much less at 25hz but 130db at 30hz.

The closest to do 122 @ 25 and 130 @30hz was TB's first sim using ND and it was about 630 liters.

And yes I know I can push the 21" past 14mm it was just a number I stuck with in all the simulations for comparing.

Volume or a different driver. You could use one of those car audio high xmax drivers that are popular now. Probably wouldn't even need a hpf if you have 30 mm or more xmax. But then you have to carefully consider inductance.

All else being equal (driver, tuning, etc), volume dictates max potential.

All else being equal (driver, tuning, etc), volume dictates max potential.

And ya inductance is always a problem. I dont know fully what it would do in a measured design outdoors with high inductance verse one very low. But Ricci likes very low so I will stick with that for now.

And the best woofer I can think of for this FLH from car audio is the Mach 5 UXL. It has 34mm Xmax and does better than the 21". In one of the larger designs the UXL needs about 4000watts and 26hz 2nd order Hpass to hit Xmax.

115db @ 20hz

125db @ 25hz

132db @ 30hz

Wow only 713 liter design.

And the best woofer I can think of for this FLH from car audio is the Mach 5 UXL. It has 34mm Xmax and does better than the 21". In one of the larger designs the UXL needs about 4000watts and 26hz 2nd order Hpass to hit Xmax.

115db @ 20hz

125db @ 25hz

132db @ 30hz

Wow only 713 liter design.

Last edited:

Everybody likes low inductance if there's a choice, it's not just Ricci. The problem is that low inductance is not cheap. UXL and TC Sounds (LMS Ultra maybe?) measure pretty close except for inductance. The inductance causes inductance hump(s) and a seriously rolled off top end. Depending on the application this may or may not be a huge problem. But the cost of the lower inductance driver is about 2x more - and lower inductance is just about the only benefit.

I know pretty much what high inductance will do, I fudge it into my sims. Within the next year or so I hope to be able to test the accuracy of my inductance tweaks, but I'm pretty sure it going to measure extremely close to my fudged sim based on a bunch of comparisons to real world measurements (mostly Ricci's measurements because he's one of the very few people I trust to measure properly).

UXL is nice but I've got something a bit different in mind for mine.

I know pretty much what high inductance will do, I fudge it into my sims. Within the next year or so I hope to be able to test the accuracy of my inductance tweaks, but I'm pretty sure it going to measure extremely close to my fudged sim based on a bunch of comparisons to real world measurements (mostly Ricci's measurements because he's one of the very few people I trust to measure properly).

UXL is nice but I've got something a bit different in mind for mine.

I wont ever be using a UXL in my designs. Just cost too much for me. Costs more than the SW152. I'd rather buy a 21 IPAL instead.

I understand it doesnt outperform a 30mm excursion car audio driver. I just have been itching for a reason to buy one is all. But not this time.

Would very interested in what your going to use also. And yes I do trust Ricci's numbers so thats what I go by on most drivers.

I would most likely use a woofer from Nick(SI) if I was going to select a car audio like driver.

I understand it doesnt outperform a 30mm excursion car audio driver. I just have been itching for a reason to buy one is all. But not this time.

Would very interested in what your going to use also. And yes I do trust Ricci's numbers so thats what I go by on most drivers.

I would most likely use a woofer from Nick(SI) if I was going to select a car audio like driver.

Last edited:

WOW.....Thanks JAG!!!!

Got me looking at some other sub types now and the 18HST in my v5 of my own design at 670l beats everything above 25hz. BAD thing is this driver wants a much larger design. It takes a Hpass at 23hz 3rd to hit Xmax around 24hz. AND it wants 4500watts to do so.

My biggest worry about a driver like the HST would be the surround is very soft. I am used to normal car audio stuff where it is very stiff but does those do have a higher Fs.

No Hpass needed at all

Got me looking at some other sub types now and the 18HST in my v5 of my own design at 670l beats everything above 25hz. BAD thing is this driver wants a much larger design. It takes a Hpass at 23hz 3rd to hit Xmax around 24hz. AND it wants 4500watts to do so.

My biggest worry about a driver like the HST would be the surround is very soft. I am used to normal car audio stuff where it is very stiff but does those do have a higher Fs.

No Hpass needed at all

WOW.....Thanks JAG!!!!

Got me looking at some other sub types now and the 18HST in my v5 of my own design at 670l beats everything above 25hz. BAD thing is this driver wants a much larger design. It takes a Hpass at 23hz 3rd to hit Xmax around 24hz. AND it wants 4500watts to do so.

My biggest worry about a driver like the HST would be the surround is very soft. I am used to normal car audio stuff where it is very stiff but does those do have a higher Fs.

No Hpass needed at all

Yeah, the no hpf required is pretty neato, eh? Gains you 3 to 6 db at the low end for free (same price as the pro drivers).

The two things to look out for here are power handling and inductance. These car audio drivers are rated for a LOT more power than the pro drivers and I'm not sure how realistic that is considering they have a 3 inch VC. Tests on data-bass show they are pretty robust and can take a heap of power, at least for a 24 second sweep. So I'm not sure if they are using thicker VC wire, more layers, or what, but I'm a bit concerned about their power ratings, although Ricci's tests indicate I might not have to be that concerned.

Inductance is the other big one. Things will NOT measure the way they sim when inductance get higher than Re (higher than a 1:1 ratio). Here's LTD02's Submaximus measured vs simulated, green line is measured black is the sim. This sim is NOT my sim and inductance is not accounted for, so naturally it's not even close to the measurement.

I know what to do about this, when I sim this horn with my inductance tweak I get VERY close results. So I know how to fudge it into the sim to get a realistic sim but this is the ONLY horn I've found with a high inductance driver and a good measurement. My inductance tweak works really well with sealed sims vs measurements and I'm excited to find out how well it works with horns other than this one shown.

Would very interested in what your going to use also. And yes I do trust Ricci's numbers so thats what I go by on most drivers.

I would most likely use a woofer from Nick(SI) if I was going to select a car audio like driver.

IMO Jakob (Sundown) is the brains and Nick is really just riding his coattails. I don't think he really know too much about what he does, what he does know comes from Jakob. He can't really hold a technical conversation and he's into ludicrous marketing claims that don't make a lot of sense. There's also loads of posts about him being extremely rude, not answering calls or emails, etc, and losing a lot of business because of it. Based on N8DOGG's experience it doesn't look like he's very good at honoring his warranties either.

So... I'd deal with Jakob / Sundown in a heartbeat and steer well clear of Nick. Jakob's drivers are going to be a lot more suited to horn use anyway (especially flh but also tapped horn).

I'll send you some info on my musings for my upcoming project if you like but I'm not posting about it. I can't send any attachments through PM so if you want to see what I'm cookin send me an email or at least a PM with your email address.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Any good plans out for FLH's?