Some more pics

Some more pics to help any body contemplating building FRP.

Some more pics to help any body contemplating building FRP.

Attachments

-

SAM_0589.JPG624.2 KB · Views: 924

SAM_0589.JPG624.2 KB · Views: 924 -

SAM_0591.JPG885.6 KB · Views: 848

SAM_0591.JPG885.6 KB · Views: 848 -

SAM_0592.JPG603.2 KB · Views: 759

SAM_0592.JPG603.2 KB · Views: 759 -

SAM_0593.JPG194.4 KB · Views: 716

SAM_0593.JPG194.4 KB · Views: 716 -

SAM_0594.JPG160.2 KB · Views: 701

SAM_0594.JPG160.2 KB · Views: 701 -

SAM_0517.jpg508.1 KB · Views: 121

SAM_0517.jpg508.1 KB · Views: 121 -

SAM_0521.JPG204.2 KB · Views: 91

SAM_0521.JPG204.2 KB · Views: 91 -

SAM_0519.JPG224.2 KB · Views: 93

SAM_0519.JPG224.2 KB · Views: 93 -

SAM_0518.JPG249 KB · Views: 93

SAM_0518.JPG249 KB · Views: 93 -

SAM_0522.JPG191.1 KB · Views: 111

SAM_0522.JPG191.1 KB · Views: 111

Some more pictures of my work.

Here we go again there will be more pictures when I can reduce the sizes

Here we go again there will be more pictures when I can reduce the sizes

Attachments

-

SAM_0522.JPG198.6 KB · Views: 112

SAM_0522.JPG198.6 KB · Views: 112 -

SAM_0524.JPG386.8 KB · Views: 85

SAM_0524.JPG386.8 KB · Views: 85 -

SAM_0527.JPG198.4 KB · Views: 85

SAM_0527.JPG198.4 KB · Views: 85 -

SAM_0530.JPG400.3 KB · Views: 88

SAM_0530.JPG400.3 KB · Views: 88 -

SAM_0529.JPG231.9 KB · Views: 87

SAM_0529.JPG231.9 KB · Views: 87 -

SAM_0528.JPG169.3 KB · Views: 88

SAM_0528.JPG169.3 KB · Views: 88 -

SAM_0532.JPG698.6 KB · Views: 89

SAM_0532.JPG698.6 KB · Views: 89 -

SAM_0533.jpg452.1 KB · Views: 138

SAM_0533.jpg452.1 KB · Views: 138 -

SAM_0535.JPG157.8 KB · Views: 131

SAM_0535.JPG157.8 KB · Views: 131 -

SAM_0536.jpg490.7 KB · Views: 95

SAM_0536.jpg490.7 KB · Views: 95

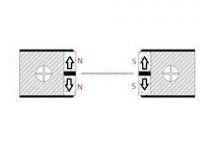

tinitus - Good advice on the magnets. The site lists them as having nearly 55 lbs of pulling force. I'm able to get them apart by sliding them apart and twisting the magnet so it is at a 90 degree angle to it's neighbor. Then I can pull them apart.

FYI, the ribbon is basically the same as my original prototype (attached) except the magnets are twice the thickness and the frame is also bigger stock.

BTW: I got my ferrite toroids today but I just found out the steel is back ordered so I don't know how much longer it will be. I won't be making much progress until it gets here.

Denis,

Did you ever get this driver up? How did it compare to your first effort?

I finally going to finish my ribbon twetter too!!

I got some vids from they!

Diy Ribbon Tweeter prototype - YouTube

Diy Ribbon Tweeter prototype2 - YouTube

Diy Ribbon Tweeter prototype 3 - YouTube

I hope u enjoy!

I got some vids from they!

Diy Ribbon Tweeter prototype - YouTube

Diy Ribbon Tweeter prototype2 - YouTube

Diy Ribbon Tweeter prototype 3 - YouTube

I hope u enjoy!

I finally going to finish my ribbon twetter too!!

I got some vids from they!

Diy Ribbon Tweeter prototype - YouTube

Diy Ribbon Tweeter prototype2 - YouTube

Diy Ribbon Tweeter prototype 3 - YouTube

I hope u enjoy!

Nice. It looks like that you run your ribbon on the 3rd video full range - not really as a tweeter. You don't use corrugations on your third prototype. More details would be welcome.

Sorry, but the 3rd video is from the first prototype!

U can see more details of entire speaker in the brazilian forum: Line Array com Ribbon Tweeter

or using google translator: Google Tradutor

U can see more details of entire speaker in the brazilian forum: Line Array com Ribbon Tweeter

or using google translator: Google Tradutor

ABJensen, i drew and paid a lathe to make it in a milling machine, it cost arround 80usd, and he gave me eight gears, and i distributes between some my friends that are making smaller ribbon tweeters, and i still got two spares!

It has square edges, but with a small knife i will scrape de nylon and round it.

It has square edges, but with a small knife i will scrape de nylon and round it.

Hi everibody, I´m new in the forum.... I dont konw how to do for some help with my DIY loudspeaker project.....

I just made a pair of 60cms. ribbon´s tweetters; that´s appear in this danish website

Byggbeskrivning för den neodymiumbestyckade band (realy good tutorial)

the ribbon cut of 400hz (works in meddle a high freqency) and the sound is amazing!!

but, Now I want to do a woofer that works good with the ribbons and down of the 400hz!!!, ......cut you please give me a hand with it, some alternatives? ...wich kind (close, open box, TL)??... frequency crossover?? 6,5 or 8"?? realy i dont know

I just made a pair of 60cms. ribbon´s tweetters; that´s appear in this danish website

Byggbeskrivning för den neodymiumbestyckade band (realy good tutorial)

the ribbon cut of 400hz (works in meddle a high freqency) and the sound is amazing!!

but, Now I want to do a woofer that works good with the ribbons and down of the 400hz!!!, ......cut you please give me a hand with it, some alternatives? ...wich kind (close, open box, TL)??... frequency crossover?? 6,5 or 8"?? realy i dont know

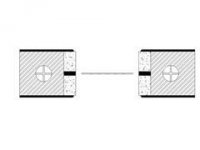

They are facing each other. In other words all the magnets on one side (one bar) are facing the same way and that is towards the other bar of magnets.

As You can see, each bar holds 2 rows of magnets. These rows are just sitting side by side and facing the same way regarding magnet flux.

Otherwise it would not work too well. hehe

As You can see, each bar holds 2 rows of magnets. These rows are just sitting side by side and facing the same way regarding magnet flux.

Otherwise it would not work too well. hehe

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Another DIY Ribbon thread