... I'm thinking too about a sort of 3D printable Bunny ,,,,

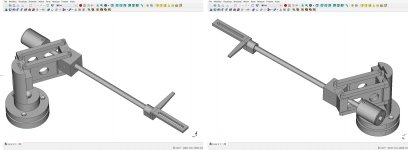

Something like this: a Doug's double pivot using quite the same geometry of the Rabbit (small differences: levers behave a bit differently from pulleys).

Very simple, sturdy construction: just 8 3D printed parts needed; all the articulations on ballpen tips. Design still to improve

carlo

Something like this: a Doug's double pivot using quite the same geometry of the Rabbit (small differences: levers behave a bit differently from pulleys).

Very simple, sturdy construction: just 8 3D printed parts needed; all the articulations on ballpen tips. Design still to improve

carlo

Attachments

I have been trying to see one of these in action. But even dealers who carry Schroder arms say, "We deal in 'real' Schroeder arms, the LT is made by Steve Dobbins." Is that really so? Not that it really matters...

The arm is not produced by Schroeder, although he's the inventor. Xact Audio is licensed to make the arm. You can contact them.

What I really wanted to see was what happens to the magnet / magnet guide proximity if the arm is yanked quickly? I presume the magnet loses track of the guide and later need to be re-aligned. The newer pictures show a different arrangment that may not allow such separation.

The magnetic guide is just a path with a curved steel rod above and a moving magnet below so there's a non-contact gap in between. Based on its arrangement, there's really no "separation" from the guiding path. It's similar to Birch but it's closer in geometry to Doug's four point cantilever. You can of course check out its patent or the video. Most of this stuff has been covered in this thread so feel free to browse.

Schroder LT

Thank you. I had been looking for a video but sometimes it is difficult to find them, thank you again for pointing me to it.

I studied the patent carefully in the past. I mostly understood how it works except for the part that the arm’s path is prescribed by a magnet following an arc made of magnetic or ferrous material.

As I expected — and visible in the video — there is wobbliness (or oscillation) around the magnetic “joint.” I would think that in normal record play (and as long as the record center hole is not seriously eccentric) that oscillation would stop quickly and not be an issue with the very gradual inward pull of the grooves.

I have several linear tracking turntables of the 70s and 80s (Harman/Kardon Rabco, ReVox, Technics (vertical), Beograms of various vintages as well as an air bearing arm mounted on a Luxman 444). What I have found is that with servo-controlled ones (especially the Revox and Technics), there is a very audible “thump” each time the servo corrects the arm’s perpendicularity. This does not happen with the Beograms for reasons I cannot fathom, or with the Rabco’s ingenious arrangement.

This new batch of Thales circle based arms coming out feels long overdue...as a teenager I used to wonder if it could be done. The answer is of course yes.

The magnetic guide is just a path with a curved steel rod above and a moving magnet below so there's a non-contact gap in between. Based on its arrangement, there's really no "separation" from the guiding path. It's similar to Birch but it's closer in geometry to Doug's four point cantilever. You can of course check out its patent or the video. Most of this stuff has been covered in this thread so feel free to browse.

Thank you. I had been looking for a video but sometimes it is difficult to find them, thank you again for pointing me to it.

I studied the patent carefully in the past. I mostly understood how it works except for the part that the arm’s path is prescribed by a magnet following an arc made of magnetic or ferrous material.

As I expected — and visible in the video — there is wobbliness (or oscillation) around the magnetic “joint.” I would think that in normal record play (and as long as the record center hole is not seriously eccentric) that oscillation would stop quickly and not be an issue with the very gradual inward pull of the grooves.

I have several linear tracking turntables of the 70s and 80s (Harman/Kardon Rabco, ReVox, Technics (vertical), Beograms of various vintages as well as an air bearing arm mounted on a Luxman 444). What I have found is that with servo-controlled ones (especially the Revox and Technics), there is a very audible “thump” each time the servo corrects the arm’s perpendicularity. This does not happen with the Beograms for reasons I cannot fathom, or with the Rabco’s ingenious arrangement.

This new batch of Thales circle based arms coming out feels long overdue...as a teenager I used to wonder if it could be done. The answer is of course yes.

Carlo,

Welcome back. And with a very interesting project, too. I hope you make it happen. There are a couple of features I really like including the dove tail support column. I'm curious about the geometry. With the nearly equal length arms, it looks like a parallelogram. Does the slight bearing offset of the guide arm change that? Do you have a plan view drawing of the arm's motion? I think you may have invented something new - again. Is the mass carried by both sets of inboard bearings?

If you might be interested, there is a suggestion from Frank Schroeder in post 944 on pg 95 and drawings by Frank and me at posts 954 and 958, both on pg 96.

Consty,

I was able to convert your files and to also download algodoo. Can you explain the math you used a bit more? I've used paper and pencil drawings for a long time and would like to try other approaches.

DD,

Thanks for the GIF conversion at 1746.

toptip,

I checked for photos of a new version of Frank's PLT, but didn't find anything. Can you post photos or links? I really appreciate being able to see it.

WalterWalter,

I think you mentioned you are working on a PLT in another thread. Is that right? And if you are, will you be posting about it here?

The Bunny has been out of service for a while so I could make a couple of changes, including a way of locking the belt. A small furniture tack locks the belt to the pivoting pulley and a small clamp locks it to the other pulley after the arm has been adjusted. I hope to get it back on a table this week.

Welcome back. And with a very interesting project, too. I hope you make it happen. There are a couple of features I really like including the dove tail support column. I'm curious about the geometry. With the nearly equal length arms, it looks like a parallelogram. Does the slight bearing offset of the guide arm change that? Do you have a plan view drawing of the arm's motion? I think you may have invented something new - again. Is the mass carried by both sets of inboard bearings?

If you might be interested, there is a suggestion from Frank Schroeder in post 944 on pg 95 and drawings by Frank and me at posts 954 and 958, both on pg 96.

Consty,

I was able to convert your files and to also download algodoo. Can you explain the math you used a bit more? I've used paper and pencil drawings for a long time and would like to try other approaches.

DD,

Thanks for the GIF conversion at 1746.

toptip,

I checked for photos of a new version of Frank's PLT, but didn't find anything. Can you post photos or links? I really appreciate being able to see it.

WalterWalter,

I think you mentioned you are working on a PLT in another thread. Is that right? And if you are, will you be posting about it here?

The Bunny has been out of service for a while so I could make a couple of changes, including a way of locking the belt. A small furniture tack locks the belt to the pivoting pulley and a small clamp locks it to the other pulley after the arm has been adjusted. I hope to get it back on a table this week.

Attachments

Thanks, but it's not a new project, Doug: it's exactly your dual pivot.

What I wanted to do was to avoid the use of ball bearings that never brought me to really good sounding results: so slowly I went back where I started from to invent the Rabbit's pulleys.

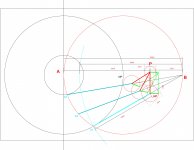

The model is only a first sketch and this is the geometry (attachment)

Now I'm playing with the 3d CAD (it's never too late) and trying to understand the secrets of 3D printing: I would like to make a simple PLT arm, a plastic toy that anyone can simply assemble with 2 cents and no effort, to begin to see directly the real problems of PLTs (geometry the last): hopefully to to find new solutions.

carlo

What I wanted to do was to avoid the use of ball bearings that never brought me to really good sounding results: so slowly I went back where I started from to invent the Rabbit's pulleys.

The model is only a first sketch and this is the geometry (attachment)

Now I'm playing with the 3d CAD (it's never too late) and trying to understand the secrets of 3D printing: I would like to make a simple PLT arm, a plastic toy that anyone can simply assemble with 2 cents and no effort, to begin to see directly the real problems of PLTs (geometry the last): hopefully to to find new solutions.

carlo

Attachments

Pardon me. From pictures it looks like you have already done that.Hi Doug,

if you dont want to make hole in belt to keep it in place you can make tiny 'L' shaped clamp (Like this) to keep it in place and if seen from above it will also indicate position of pulleys.

Regards

Regards

Printable Twin P - some steps

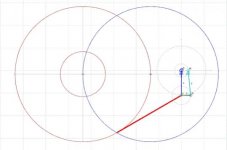

*.gif - geometry verified with linkage2, not so bad.

*.zip - Freecad 3d model converted to *.step format - editable with many free 3dcads and viewers.

problem: too rigid horizontal articulation (eccentric LPs)

next steps:

1 - compensations for shrinking? beveling?

2 - conversion to mesh, slicing, print settings .....test printing

completely unknown territory, for me

carlo

*.gif - geometry verified with linkage2, not so bad.

*.zip - Freecad 3d model converted to *.step format - editable with many free 3dcads and viewers.

problem: too rigid horizontal articulation (eccentric LPs)

next steps:

1 - compensations for shrinking? beveling?

2 - conversion to mesh, slicing, print settings .....test printing

completely unknown territory, for me

carlo

Attachments

Thanks DD, but let's wait to see if it's correctly 3d printable, and if it works ...

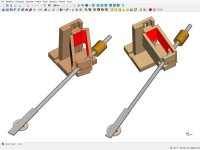

It could also be done this way, old-style: all wood. with articulations made with a ribbon of thin fabric glued with vinyl. (highlighted in red). Hoping that my friend Doug will like it, and Nanook too...

Simplifying is the real fun.

Carlo

It could also be done this way, old-style: all wood. with articulations made with a ribbon of thin fabric glued with vinyl. (highlighted in red). Hoping that my friend Doug will like it, and Nanook too...

Simplifying is the real fun.

Carlo

Attachments

According to what my friend tells me, the problems is not that much in the printer's precision (even less than 0.1 mm) as for the various materials, subject to thermal shrinkage and deformations related to the shapes and thickness used. Since a 2 - 5% shrinking is normal, it is used a test print for measuring, and then make corrections. I have planned to put just pilot holes, and then do the drilling for the ballpen tips (those axes are the only really critical measures) using a metal guide.

skating: you're right - this is only a compact version of a Birch based tonearm.

But the question is more complex, I had posted an hypothesis (#1733) on the forces that act on the Rabbit -arm, hoping that some expert would discuss those evident problems that maybe affect all the PLT tonearms.

Crucial issues imho, but nobody seemed to be interested.

Really strange.

carlo

skating: you're right - this is only a compact version of a Birch based tonearm.

But the question is more complex, I had posted an hypothesis (#1733) on the forces that act on the Rabbit -arm, hoping that some expert would discuss those evident problems that maybe affect all the PLT tonearms.

Crucial issues imho, but nobody seemed to be interested.

Really strange.

carlo

Hi all.

I tried several times to analyze the tracking forces of a Birch, unfortunately my school memories are so confused that I think my graphic analysis is full of errors. So i'm posting this, hoping that some friend will want to correct or even better to redo completely. I believe that the relationship between the forces that move these arms (thales, birch, and so on) should be investigated deeply, going beyond the "simple" skating problem

Carlo

skating: you're right - this is only a compact version of a Birch based tonearm.

But the question is more complex, I had posted an hypothesis (#1733) on the forces that act on the Rabbit -arm, hoping that some expert would discuss those evident problems that maybe affect all the PLT tonearms.

Crucial issues imho, but nobody seemed to be interested.

Really strange.

carlo

Carlo,

Nobody interested in skating? I'm interested in skating. Internet audio forums are awash with posts on problems with skating, how to determine the proper amount of anti-skating, and the if all else fails bury-your-head-in-the-sand arguments that the issue of skating is overblown and you don’t need to worry about it anyway. I have followed this thread since its inception and have read every post. Many commercial PLT designs were manufactured over the years, and many are available now. Many ingenious ideas have been presented on this thread. To answer your last question up front, I will put on my flame-proof suit and proclaim that all (with maybe one possible exception, the Klaudio) PLT tonearms will skate and, if a particular PLT doesn’t appear to exhibit skating tendencies, it’s likely because the linkage pivots are saddled with excessive friction. This is the bargain that you make with the devil when you go with a PLT design. I myself consider the negative side-effects of skating and bad bearings to be worse than tracking error.

Another concern with PLT’s, such as the Rabbit, is that the arm moves forward as it arcs toward the record center. I submit that this has a multiplying effect on skating force and that makes the skating effect greater than that seen on a conventional pivoted arm for which skating force is calculated by offset angle and overhang. Calculating skating forces on multi-linkage arm movements is not as simple. Plus, this forward component of motion will exaggerate wow effects due to off-center disks.

This is why I proposed my “String Test” as a Litmus Test for answering the question “will it skate”? The string test is easy to perform, the results are easy to observe and understand, and the observer can come to intelligent conclusions. Deep mathematical investigation could be done, but mathematically modeling forces in a multi-linkage arm is above my station. I’d be interested in the results, though.

Ray K

Klaudio

Angling for 90° - tangential pivot tonearms

String Test:

Angling for 90° - tangential pivot tonearms

Angling for 90° - tangential pivot tonearms

Thanks for your intervention Ray, I know your important contribution on these topics.

Your posts, like those of other experts of this thread have taught me a lot and convinced that it is almost impossible to design a PLT without skating. Only the Klaudio and the Schroeder are said to be immune - the first I do not understand (incredible quality build) how can it move with that cam and a dozen bearings, for the second are mentioned "trade secrets" that I can not even imagine.

If we are working on PLTs, it is to avoid tracking error and skating. Building PLTs, doing your test, and practically measuring the very weak forces that can move them, I realized that the situation is more complex than I could think. Not only we have skating, but tracking forces (side force + stylus drag) are composed in variable way from outer to inner grooves. Problems that -imho- put serious doubts on the research itself.

That's why I had abandoned the practical experimentation and posted that graphic analysis (maybe wrong). hoping that those experiments would develop a profitable debate among the experts:

Knowing that these arms skate is not enough, we need to know how and how much it is generated, if we want to design better ones.

thanks again - carlo

Smart question, as always, Hiten

Your posts, like those of other experts of this thread have taught me a lot and convinced that it is almost impossible to design a PLT without skating. Only the Klaudio and the Schroeder are said to be immune - the first I do not understand (incredible quality build) how can it move with that cam and a dozen bearings, for the second are mentioned "trade secrets" that I can not even imagine.

If we are working on PLTs, it is to avoid tracking error and skating. Building PLTs, doing your test, and practically measuring the very weak forces that can move them, I realized that the situation is more complex than I could think. Not only we have skating, but tracking forces (side force + stylus drag) are composed in variable way from outer to inner grooves. Problems that -imho- put serious doubts on the research itself.

That's why I had abandoned the practical experimentation and posted that graphic analysis (maybe wrong). hoping that those experiments would develop a profitable debate among the experts:

Knowing that these arms skate is not enough, we need to know how and how much it is generated, if we want to design better ones.

thanks again - carlo

Smart question, as always, Hiten

Last edited:

Skating force is the vector component of stylus drag force pointing to the center of record. The other vector component is pointing to the arm pivot point. If the drag force varies, the skating force varies, too. But I don't see any relation with offset error.For a typical 9 inch gimbal bearing tonearm with offset headshell, is the skating force same across the record ? What happens at two null points ?

Thanks and regards.

Carlo,

I myself consider the negative side-effects of skating and bad bearings to be worse than tracking error.

This is why I proposed my “String Test” as a Litmus Test for answering the question “will it skate”? The string test is easy to perform, the results are easy to observe and understand, and the observer can come to intelligent conclusions. Deep mathematical investigation could be done, but mathematically modeling forces in a multi-linkage arm is above my station. I’d be interested in the results, though.

Ray

Yes, and stiff tonearm wires, too. It seems nobody discusses those issues

As to string test, I somehow missed description. May you post a link, please?

Currently I'm using a flat non-modulated record for that purpose. It allows anyone to see, how skating force works on different groves, and I would recommend it to anyone, who owes a turntable.

Last edited:

I mean flat naked record with no grooves at all, so the stylus able to slide inside, if a skating force is there, or outside, if anti-skating set too much. If your arm has no skating force - stylus will stay in any part of record, there you put it.

If you possess a substantial record collection, usually there are some records with a naked side.

And, yes, I know about limitations of that method.

If you possess a substantial record collection, usually there are some records with a naked side.

And, yes, I know about limitations of that method.

Thanks lcsaszar. So Main causes of skating are stylus drag and position of cartridge-stylus with respect to pivot. From other thread I read Lucky Dog's observation that after few plays the groove walls smoothen and there is less friction (Pictures of that were also there in the thread) so a light weight high compliance cartridge would exhibit less skating force I presume.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms