Carlo,

Congratulations on your latest version. Beautiful work as always. I think the twin arm arrangement is a major improvement and I also like the many small details you've included.

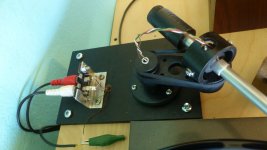

Here's my completed effort at the Bunny.

Congratulations on your latest version. Beautiful work as always. I think the twin arm arrangement is a major improvement and I also like the many small details you've included.

Here's my completed effort at the Bunny.

Attachments

Last edited:

Well done Doug, exactly what I like the best: for me the real challenge is to find simple solutions to complex problems, not the opposite. How do you say, mouse trap technology? For many it's hard to accept that a round rod in a square hole can be a much more precise fit than a lapped one, accurately matched in oilite bushing. Or that a cheap swatch, using 1/3 of gears, works exactly like a patek.

Apparently you're already listening your arm: are there differences with your previous achievements? problems with the infamous belt? Frankly the only advantage of a Rabbit version it's for set up ease*. Or to have a nicer conversation piece in the living room.

Seems that Rabbit is - la scoperta dell'acqua calda - the discovery of hot water, as we say here. Of course there are arms that seem to use belts for strange geometries (e.g. renderings on #937), but I was hoping that was the first using a belt to guide a Birch (angles relationship). Amen, after all even the string tonearm of the great Bill Firebaugh was somehow done before.

# 28 DIY tensioned string suspended tonearm

carlo

* hint: put some marks on pulleys to realign them to the crank, if inadvertently you slide the belt

Apparently you're already listening your arm: are there differences with your previous achievements? problems with the infamous belt? Frankly the only advantage of a Rabbit version it's for set up ease*. Or to have a nicer conversation piece in the living room.

Seems that Rabbit is - la scoperta dell'acqua calda - the discovery of hot water, as we say here. Of course there are arms that seem to use belts for strange geometries (e.g. renderings on #937), but I was hoping that was the first using a belt to guide a Birch (angles relationship). Amen, after all even the string tonearm of the great Bill Firebaugh was somehow done before.

# 28 DIY tensioned string suspended tonearm

carlo

* hint: put some marks on pulleys to realign them to the crank, if inadvertently you slide the belt

Last edited:

This arm is maybe a Bunny plus two. It has four bearings instead of two, but really not that much more complicated.

As far as I can tell, when set up right, it tracks accurately and there is no visible stylus distortion or hunting. The cartridge is a high compliance, low VTF Shure M91, which I thought would be a good challenge.

How does it sound? I think maybe it doesn't have a sound. I think it does very well at getting out of the way of the cartridge and just letting it do it's job. I am enjoying what I'm hearing.

Pulley/belt slippage when the arm is handled is a nuisance and I'm working on ways to prevent that without gluing. I saw the index marks on the new Rabbit, but I have no place to put them so I made the arm rest in the photo. If the arm is aligned in the rest, it is aligned for the record.

Oh, I almost forgot: It failed the string test.

As far as I can tell, when set up right, it tracks accurately and there is no visible stylus distortion or hunting. The cartridge is a high compliance, low VTF Shure M91, which I thought would be a good challenge.

How does it sound? I think maybe it doesn't have a sound. I think it does very well at getting out of the way of the cartridge and just letting it do it's job. I am enjoying what I'm hearing.

Pulley/belt slippage when the arm is handled is a nuisance and I'm working on ways to prevent that without gluing. I saw the index marks on the new Rabbit, but I have no place to put them so I made the arm rest in the photo. If the arm is aligned in the rest, it is aligned for the record.

Oh, I almost forgot: It failed the string test.

Attachments

Last edited:

Thanks for the good news, Doug: an arm that does not sound is exactly what I'm always looking for.

I was anxious to have a competent opinion because I do not trust myself at all: to judge my arms I count on good friends, but even more on "not so good" ones. So after you, I hope that this arm will be built by those who think it's just a toy because it can be done with 4 cents of bearings, and not spending 10 grands. I speak for myself of course: Altmann and Nanook unipivots changed completely my point if view.

Compliance: I feel that these arms are suitable for high compliance - low VTF cartridges (light short arm, little counterweight etc) but I only know how to calculate approximately the eff. mass of a normal arm, and this is very different.

Four bearings is the way to go, i had noticed that thickness, and the aligning arm rest is really clever, i'll copy for sure. Let me know how you'll hold the belt: I had seen that gluing must be done just in a little dot (not reliable) otherwise the rotation is no longer uniform

ciao - carlo

string test: someday i'll post the vector breakdown for this arm: maybe completely wrong, but maybe the occasion for interesting contributions of experts

I was anxious to have a competent opinion because I do not trust myself at all: to judge my arms I count on good friends, but even more on "not so good" ones. So after you, I hope that this arm will be built by those who think it's just a toy because it can be done with 4 cents of bearings, and not spending 10 grands. I speak for myself of course: Altmann and Nanook unipivots changed completely my point if view.

Compliance: I feel that these arms are suitable for high compliance - low VTF cartridges (light short arm, little counterweight etc) but I only know how to calculate approximately the eff. mass of a normal arm, and this is very different.

Four bearings is the way to go, i had noticed that thickness, and the aligning arm rest is really clever, i'll copy for sure. Let me know how you'll hold the belt: I had seen that gluing must be done just in a little dot (not reliable) otherwise the rotation is no longer uniform

ciao - carlo

string test: someday i'll post the vector breakdown for this arm: maybe completely wrong, but maybe the occasion for interesting contributions of experts

Here some photos, thank for your attention, Walter. Since I had already talked about the behavior of the test-Bunny I thought useless to post this. Does it sound better than the Bunny? yes, but certainly not 10 times, which is the time needed to build it. Usually I don't speak of sound, leaving it gladly to those who have something to sell, or to prove.

disclaimer -- even if it can be done in a weekend or 2 and with a few tools, I can not recommend the Bunny as a first time arm: measures must be rigorous, axes perfectly parallel and setup simply maniacal (just a small leveling error leads to non-uniform rotation). Doug, who has a lot of experience in Birch-type arms may be more exhaustive than me

Reinventing the belt

Since Schroeder talked about, I did a little search on this thread (a deep gold-mine, thanks Dd) and elsewhere, and found this:

# 349 - japanese stringed rotating headshell tonearm -- # 352 - A. Wolff 1985 - stringed rotating headshell tonearm (nearer to polygon type - Garrard zero & Co - than to what we're dealing)

# 365 - G. Guy 1952 - pulley Thales (rotating stylus - interesting, but almost useless with modern cartridges)

# 937 - Miib - 2015 - strange reversed geometry "compass" arm. (I noticed it, but did not understand how it worked (??) or that it had pulleys)

US4580258A - Phonograph - Google Patents (1986 - Servo assisted - off topic; non Birch geometry, not explicited)

No info (except that video) found on that Schroeder arm. From what I can see from (not so clear) photos seems that the pivot fixed to the plinth is the one in front, which would make it look more like the Miib than a Birch.

As I said many time ago, after a century and 1500 types of commercial tonearms around is unlikely to invent something really new. Just little mods, useful if possible.

ciao a tutti - carlo

disclaimer -- even if it can be done in a weekend or 2 and with a few tools, I can not recommend the Bunny as a first time arm: measures must be rigorous, axes perfectly parallel and setup simply maniacal (just a small leveling error leads to non-uniform rotation). Doug, who has a lot of experience in Birch-type arms may be more exhaustive than me

Reinventing the belt

Since Schroeder talked about, I did a little search on this thread (a deep gold-mine, thanks Dd) and elsewhere, and found this:

# 349 - japanese stringed rotating headshell tonearm -- # 352 - A. Wolff 1985 - stringed rotating headshell tonearm (nearer to polygon type - Garrard zero & Co - than to what we're dealing)

# 365 - G. Guy 1952 - pulley Thales (rotating stylus - interesting, but almost useless with modern cartridges)

# 937 - Miib - 2015 - strange reversed geometry "compass" arm. (I noticed it, but did not understand how it worked (??) or that it had pulleys)

US4580258A - Phonograph - Google Patents (1986 - Servo assisted - off topic; non Birch geometry, not explicited)

No info (except that video) found on that Schroeder arm. From what I can see from (not so clear) photos seems that the pivot fixed to the plinth is the one in front, which would make it look more like the Miib than a Birch.

As I said many time ago, after a century and 1500 types of commercial tonearms around is unlikely to invent something really new. Just little mods, useful if possible.

ciao a tutti - carlo

Attachments

Last edited:

As I said many time ago, after a century and 1500 types of commercial tonearms around is unlikely to invent something really new. Just little mods, useful if possible.

Carlo, it is extremely difficult and challenging, however still not impossible. Shroeder TL with magnetic guide is a real breakthrough, and at the same time it is simple, reasonable and completely applicable design. IMO deserves something like Noble Prize in the field of vinyl reproduction.

As to your arm, beautiful piece of work. I think three point angle adjustment of base could help to solve leveling troubles. And I'm kind of jealous as to your access to lathe.

Carlo, it is extremely difficult and challenging, however still not impossible. Shroeder TL with magnetic guide is a real breakthrough, and at the same time it is simple, reasonable and completely applicable design. IMO deserves something like Noble Prize in the field of vinyl reproduction.

As to your arm, beautiful piece of work. I think three point angle adjustment of base could help to solve leveling troubles. And I'm kind of jealous as to your access to lathe.

Yes, not impossible, unlikely. Of Schroeder Tl i think exactly the same , i said just that quite every arm has his ancestors.

Leveling: you may note that the arm base has 3 screws for that. in drawings you may see how it works.

lathe: a chinese lathe costs a fraction of a good arm, and is much more fun. I bought one long time ago to make spares and mods for the view cameras used in our studio

ciao - carlo

Leveling: you may note that the arm base has 3 screws for that. in drawings you may see how it works.

lathe: a chinese lathe costs a fraction of a good arm, and is much more fun. I bought one long time ago to make spares and mods for the view cameras used in our studio

ciao - carlo

Hi all.

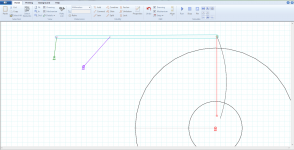

I tried several times to analyze the tracking forces of a Birch, unfortunately my school memories are so confused that I think my graphic analysis is full of errors. So i'm posting this, hoping that some friend will want to correct or even better to redo completely. I believe that the relationship between the forces that move these arms (thales, birch, and so on) should be investigated deeply, going beyond the "simple" skating problem

Carlo

With this chart, dear friends, I end my active diyer presence in this thread, which - rightly - deals more with theoretical problems than with practical solutions. I feel that i'm driving off road.

I thank all who have kindly followed my trials and my errors, and in particular Direct driver with his influential observations, Doug with his experience and smart solutions, 2wice with his remarkable mathematical skills.

I remain of the idea that the problem of these arms lays in the driving mechanisms and the management of the small tracking forces. My little attempt was, both for Thales and Birch types, to take care of angles relationship instead of guiding paths, as it was previously done. And I hope this would be further investigated with greater capacity than mine. I will obviously continue to follow your research, from which I have learned so much.

I tried several times to analyze the tracking forces of a Birch, unfortunately my school memories are so confused that I think my graphic analysis is full of errors. So i'm posting this, hoping that some friend will want to correct or even better to redo completely. I believe that the relationship between the forces that move these arms (thales, birch, and so on) should be investigated deeply, going beyond the "simple" skating problem

Carlo

With this chart, dear friends, I end my active diyer presence in this thread, which - rightly - deals more with theoretical problems than with practical solutions. I feel that i'm driving off road.

I thank all who have kindly followed my trials and my errors, and in particular Direct driver with his influential observations, Doug with his experience and smart solutions, 2wice with his remarkable mathematical skills.

I remain of the idea that the problem of these arms lays in the driving mechanisms and the management of the small tracking forces. My little attempt was, both for Thales and Birch types, to take care of angles relationship instead of guiding paths, as it was previously done. And I hope this would be further investigated with greater capacity than mine. I will obviously continue to follow your research, from which I have learned so much.

Attachments

Hi all,

I have also studied carefully Shroder's LT and I could not be at peace with his guided path approach. Not that it doesn't work. It does but it's too much for us, normal DIY-ers.

The main problem here is that the paths involved are not circles but cardioids. It had to be a way to do it using simple linkage. And it is!

The good news is that for a limited range of angles and carefully chosen sizes and proportions, those cardioids can be approximated with circles!

This is how I created a linkage2 contraption that works great. Check the attachments. Look for the red line crossing at all times the spindle almost perfectly through its center

In case you also use linkage2, I can share the simulation file too.

What do you think?

I have also studied carefully Shroder's LT and I could not be at peace with his guided path approach. Not that it doesn't work. It does but it's too much for us, normal DIY-ers.

The main problem here is that the paths involved are not circles but cardioids. It had to be a way to do it using simple linkage. And it is!

The good news is that for a limited range of angles and carefully chosen sizes and proportions, those cardioids can be approximated with circles!

This is how I created a linkage2 contraption that works great. Check the attachments. Look for the red line crossing at all times the spindle almost perfectly through its center

In case you also use linkage2, I can share the simulation file too.

What do you think?

Attachments

Thanks Walter for your flattering comment.

Especially coming after Carlo's #1730 quoted by you in #1731

I'm not an intellectual property expert but it's hard to believe that there is any mechanical device that was not yet invented since the industrial revolution onward.

As for the cardioid (see the attachment), I tried by all means to avoid it due to the hurdles faced for implementing it. Carlo's tonearm looks terrific but I wouldn't want to be in the position to set it up or especially to maintain that set up due to permanent risk of slippage.

Someone here even suggested using a gear but it's hard to make a gear that poses a friction force in the realm of milligrams as requested for a really good tonearm.

Especially coming after Carlo's #1730 quoted by you in #1731

I'm not an intellectual property expert but it's hard to believe that there is any mechanical device that was not yet invented since the industrial revolution onward.

As for the cardioid (see the attachment), I tried by all means to avoid it due to the hurdles faced for implementing it. Carlo's tonearm looks terrific but I wouldn't want to be in the position to set it up or especially to maintain that set up due to permanent risk of slippage.

Someone here even suggested using a gear but it's hard to make a gear that poses a friction force in the realm of milligrams as requested for a really good tonearm.

Attachments

Toothed or timing belts are ideal for the slippage issue but are awful at friction. These belts are mainly designed for transferring a considerable deal of force with precise positional consistency as needed in printers, scanners, 3D printers, etc.

It would be the same as using a bicycle chain in a clockwork

It would be the same as using a bicycle chain in a clockwork

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms