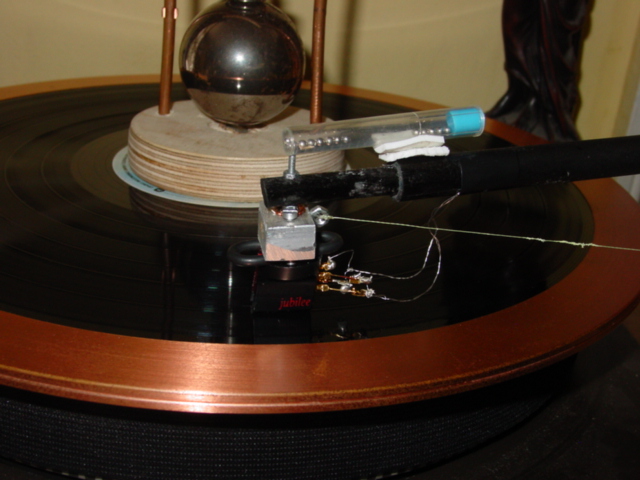

The tonearm I have is made by myself and it is a hybrid between Schroeder and the Well Tempered with a length of 60 cm. The wire is 2 meter long. I found out that it becomes better this way.

Care to tell us more about your DIY tonearm? It appears the headshell pivot point is not above the stylus.

.

Hi Frank!

I have one question for you. If I understand it correctly, there is no anti skating device on your tone arm. So, I assume that there is no skating force exists.

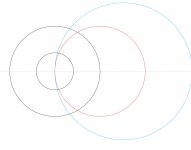

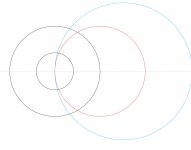

Please see the drawing. As I understand, if the stylus travels on the red line, there is no skating force. If the stylus travels on blue line, skating force doese exist although it is smaller than the skating force on regular pivot arm.

Regards,

Jim

I have one question for you. If I understand it correctly, there is no anti skating device on your tone arm. So, I assume that there is no skating force exists.

Please see the drawing. As I understand, if the stylus travels on the red line, there is no skating force. If the stylus travels on blue line, skating force doese exist although it is smaller than the skating force on regular pivot arm.

Regards,

Jim

Hi Jim,

The stylus(assuming the cart was mounted in a LT arm) travels neither on the blue nor on the red line(if I interpret your drawing correctly).

It is not correct, that there is no skating force present if it were to travel on the red line only.

If I could imbed a video here, I could show what I demoed a few times at the High End Show in Munich last weekend with a blank test disc...

Cheers,

Frank

The stylus(assuming the cart was mounted in a LT arm) travels neither on the blue nor on the red line(if I interpret your drawing correctly).

It is not correct, that there is no skating force present if it were to travel on the red line only.

If I could imbed a video here, I could show what I demoed a few times at the High End Show in Munich last weekend with a blank test disc...

Cheers,

Frank

Skating forces happens because the arm, or the cartridge is mounted with an offset angle, thus the friction has an "arm" respective to the horizontal pivot point of the tone arm. The Thales "easy" has skating forces that changes from positive to negative as it plays the record.

BTW the tracking error on the 9" Thales is not too much better than what you can do with a 10" "normal" tonearm.

BTW the tracking error on the 9" Thales is not too much better than what you can do with a 10" "normal" tonearm.

Frank,Hi Jim,

The stylus(assuming the cart was mounted in a LT arm) travels neither on the blue nor on the red line(if I interpret your drawing correctly).

It is not correct, that there is no skating force present if it were to travel on the red line only.

If I could imbed a video here, I could show what I demoed a few times at the High End Show in Munich last weekend with a blank test disc...

Cheers,

Frank

Thanks for replying!

Can you provide an external link for the video?

Regards,

Jim

the tracking error on the 9" Thales is not too much better than what you can do with a 10" "normal" tonearm.

Good point. That's why I am disappointed to see the Easy arm not using the Simplicity arm's Garrard Zero type of geometry, instead they opted to use a Burne-Jones arrangement. I think the Easy's goal is more about reducing skating force than about tangential accuracy. I really like the Easy arm's elegant construction over the Simplicity. It's also visually more pleasing to me.

I guess the manufacture does not want to created a marketing conflict of the two arms if they are too similar in design. It might even be possible the Easy can outperform the Simplicity if both use the SAME geometry! It would be interesting how the Easy would implement an antiskating scheme. I can foresee them maybe coming up with a model priced right in between the Simplicty ($9200) and Easy ($5800), perhaps a $7500 arm combining Easy's construction with Simplicity's geometry of .006º tracking error.

I also noticed they have just discontinued the Original model that allows zero tracking error so that infers its complexity is not worth the hassle and not enough sales to justify its production.

.

The image link to the WKarlson tonearm disappeared in post#544 so I am reposting it so one can compare it to the Schuchtronic tonearm.

Still not sure if the Karlson arm is a tangential tracking arm and information is limited.

Still not sure if the Karlson arm is a tangential tracking arm and information is limited.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Finally, the Thales EASY tonearm in action, short video and long video.

Last edited:

Attachments

Last edited:

birch approach

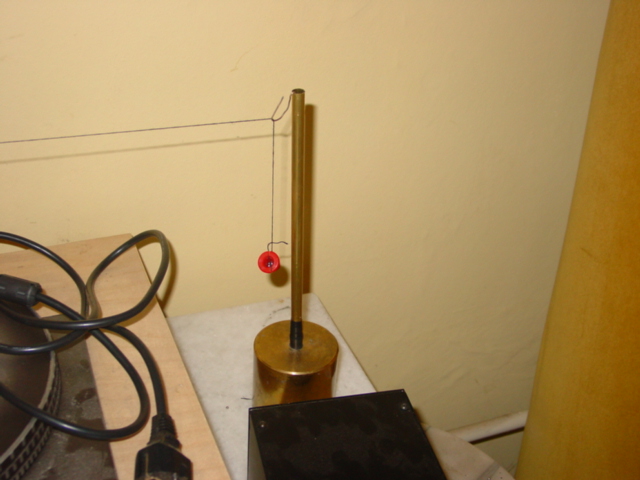

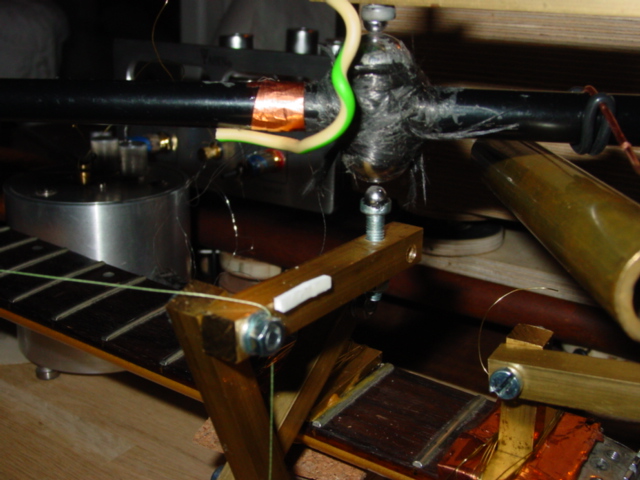

I've just been testing this arm. It's based on my understanding the Thales-Birch alignment DD posted and, obviously, in part on Frank Schroeder's LT. I also waded as best I was able through Mark Kelly's math thicket to glean what I could. They are both blameless for the results. The posts from Frank, Mark, and DD between pages 21 and 27 of this thread were very helpful

I've been fascinated by Frank's pivoted LT for several years and wanted to attempt something similar that wouldn't infringe on patents or otherwise step on toes.

The arm works and with an M44-G/N44ED @ 3 gr produces pretty good sound, very detailed. As the photos show, it maintains fairly accurate tangency across the record and doesn't mis-track. When everything is correctly adjusted, the stylus is centered in the cartridge and doesn't hunt at all.

The point B pivot is a Heim joint. I know there's gonna be flak for that, but it does deal with all the functions of that point and operates smoothly. There are a multitude of options for implementing point B, some not involving a point B at all - the Heim joint was just simplest. Since the weight of the tube is carried by the primary pivot arm, the joint can be adjust so the tube barely touches the hole it rides in.

I've just been testing this arm. It's based on my understanding the Thales-Birch alignment DD posted and, obviously, in part on Frank Schroeder's LT. I also waded as best I was able through Mark Kelly's math thicket to glean what I could. They are both blameless for the results. The posts from Frank, Mark, and DD between pages 21 and 27 of this thread were very helpful

I've been fascinated by Frank's pivoted LT for several years and wanted to attempt something similar that wouldn't infringe on patents or otherwise step on toes.

The arm works and with an M44-G/N44ED @ 3 gr produces pretty good sound, very detailed. As the photos show, it maintains fairly accurate tangency across the record and doesn't mis-track. When everything is correctly adjusted, the stylus is centered in the cartridge and doesn't hunt at all.

The point B pivot is a Heim joint. I know there's gonna be flak for that, but it does deal with all the functions of that point and operates smoothly. There are a multitude of options for implementing point B, some not involving a point B at all - the Heim joint was just simplest. Since the weight of the tube is carried by the primary pivot arm, the joint can be adjust so the tube barely touches the hole it rides in.

Attachments

I have not been able to follow this completely, but am I right in assuming that it is ony stylus friction that moves / keeps the stylus at the optimum point ???? What type and quality are the bearings?

BTW- nice execution, interesting .. if only time will permit me...... Oh well, some time....

BTW- nice execution, interesting .. if only time will permit me...... Oh well, some time....

AuroraB,

Thanks for your reply. Yes, the stylus does the work. Currently, the pivot arm bearings are a mix of two small hybrid ceramic and two larger stainless steel. The steel bearings are working well enough, but I've ordered hybrid ceramic replacements and I expect them to be significantly better. A critical factor is pre-loading the bearings. The vertical plane bearings are tiny flanged air tool bearings.

This isn't an easy DIY, but can be done with a modest shop like mine.

I really hope someone else takes a shot at this so we can compare notes.

Thanks for your reply. Yes, the stylus does the work. Currently, the pivot arm bearings are a mix of two small hybrid ceramic and two larger stainless steel. The steel bearings are working well enough, but I've ordered hybrid ceramic replacements and I expect them to be significantly better. A critical factor is pre-loading the bearings. The vertical plane bearings are tiny flanged air tool bearings.

This isn't an easy DIY, but can be done with a modest shop like mine.

I really hope someone else takes a shot at this so we can compare notes.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms