Hi Brian

Made a frame of wood and drilled holes through the sides and put long screw's in.

Then I glue the frame to mylar.

I put a aluminum profile over the screw's and mount springs.

Attach the profile to the speaker mdf and now I can adjust the tension of the mylar.

Then I use aluminum tape 9mm wide from farnell for the conductors.

Rob

Made a frame of wood and drilled holes through the sides and put long screw's in.

Then I glue the frame to mylar.

I put a aluminum profile over the screw's and mount springs.

Attach the profile to the speaker mdf and now I can adjust the tension of the mylar.

Then I use aluminum tape 9mm wide from farnell for the conductors.

Rob

Henry, you are a maniac. In the best possible way.I marvel at all your work.

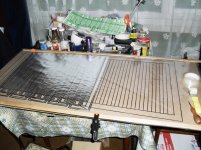

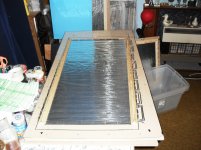

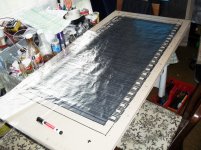

Some more for you to marvel at!! Finished latest design using 80 meters of 4.5 mm wide tape. The first 45 meters ran out before I realized. So the diaphragm is in 2 unequal parts which caused problems when wiring in parallel and the top half is louder than the bottom half. You live and learn. It is running with my first epsilon layout design (with the glued magnets) The small A4 sized design is my next rebuild.

Then I may finish my planar headphones next.

Then I may finish my planar headphones next.Attachments

-

SAM_0137.JPG857.7 KB · Views: 761

SAM_0137.JPG857.7 KB · Views: 761 -

SAM_0146.JPG759.1 KB · Views: 693

SAM_0146.JPG759.1 KB · Views: 693 -

SAM_0147.JPG713 KB · Views: 650

SAM_0147.JPG713 KB · Views: 650 -

SAM_0148.JPG734.1 KB · Views: 624

SAM_0148.JPG734.1 KB · Views: 624 -

SAM_0150.JPG823.8 KB · Views: 586

SAM_0150.JPG823.8 KB · Views: 586 -

SAM_0151.JPG760.4 KB · Views: 124

SAM_0151.JPG760.4 KB · Views: 124 -

SAM_0152.JPG716.4 KB · Views: 127

SAM_0152.JPG716.4 KB · Views: 127 -

SAM_0153.JPG905.7 KB · Views: 127

SAM_0153.JPG905.7 KB · Views: 127 -

SAM_0140.JPG817.3 KB · Views: 170

SAM_0140.JPG817.3 KB · Views: 170 -

SAM_0139.JPG808.8 KB · Views: 147

SAM_0139.JPG808.8 KB · Views: 147

MY A4 SIZE REBUILD.

Some more photos of my latest rebuild. The last but one is the old diaphragm, and the last photo is the new tape 2.25 mm wide to fit magnets on the rebuilt diaphragm using epsilon layout. I think it's called being obsessive.!! After this it's my planar headphones, to be finished. Then it's back to the rebuilds, all that tape cutting, about 300 meters.

I think it's called being obsessive.!! After this it's my planar headphones, to be finished. Then it's back to the rebuilds, all that tape cutting, about 300 meters.

Some more photos of my latest rebuild. The last but one is the old diaphragm, and the last photo is the new tape 2.25 mm wide to fit magnets on the rebuilt diaphragm using epsilon layout.

Attachments

-

SAM_0163.JPG703.2 KB · Views: 132

SAM_0163.JPG703.2 KB · Views: 132 -

SAM_0162.JPG680.5 KB · Views: 115

SAM_0162.JPG680.5 KB · Views: 115 -

SAM_0160.JPG675.5 KB · Views: 103

SAM_0160.JPG675.5 KB · Views: 103 -

SAM_0159.JPG779.1 KB · Views: 96

SAM_0159.JPG779.1 KB · Views: 96 -

SAM_0158.JPG682.9 KB · Views: 120

SAM_0158.JPG682.9 KB · Views: 120 -

SAM_0157.JPG729.6 KB · Views: 126

SAM_0157.JPG729.6 KB · Views: 126 -

SAM_0155.JPG735.8 KB · Views: 146

SAM_0155.JPG735.8 KB · Views: 146 -

SAM_0154.JPG777.7 KB · Views: 190

SAM_0154.JPG777.7 KB · Views: 190 -

SAM_0164.JPG526.4 KB · Views: 123

SAM_0164.JPG526.4 KB · Views: 123 -

SAM_0156.JPG737.6 KB · Views: 194

SAM_0156.JPG737.6 KB · Views: 194

Last edited:

Some more photos of my latest rebuild. The last but one is the old diaphragm, and the last photo is the new tape 2.25 mm wide to fit magnets on the rebuilt diaphragm using epsilon layout.I think it's called being obsessive.!! After this it's my planar headphones, to be finished. Then it's back to the rebuilds, all that tape cutting, about 300 meters.

Hi Henry

nice work!

What's the resistance of the small planars?

and, how does they sound? mine are a bit weak on bass... (size matters)

Regards

Pedro

I have stopped work on these at the moment as I ruined the diaphragm fitting it to the surround, and I have not heard it at this time. The resistance of the old diaphragm was 1.4 ohms, the new one is 4.4 ohms.Hi Henry

nice work!

What's the resistance of the small planars?

and, how does they sound? mine are a bit weak on bass... (size matters)

Regards

Pedro

Does anyone know what technique Analysis uses to solder to their aluminum conductors? In some thread I haven't yet found again there was a discussion of techniques for breaking through the aluminum oxide layer while soldering but that approach doesn't seem applicable to very thin (5.5 micron) aluminum foil.

Few

Few

Few,is this the one you were looking for?

http://www.diyaudio.com/forums/planars-exotics/197412-soldering-aluminium.html#post2725831

jer

http://www.diyaudio.com/forums/planars-exotics/197412-soldering-aluminium.html#post2725831

jer

One product that works is this:

An externally hosted image should be here but it was not working when we last tested it.

Hi Few

Just buy aluminium solder from Farnell Farnell Export

For aluminium foil it works perfect.

Rob

Just buy aluminium solder from Farnell Farnell Export

For aluminium foil it works perfect.

Rob

Thanks jer, that's the one I remembered. Unfortunately I don't think it's applicable to thin foils. I fear the mechanical scrubbing step would beat them up too much.

I'm a bit lost with the Farnell link but figured I'd make yet another attempt to find a promising source of solder for aluminum. KappAloy9 popped up but I haven't yet found a way to buy it.

Is that conventional Ersin multicore? I would have thought it would have the same problems with the oxide as other electronic solders. No?

I'm a bit lost with the Farnell link but figured I'd make yet another attempt to find a promising source of solder for aluminum. KappAloy9 popped up but I haven't yet found a way to buy it.

Is that conventional Ersin multicore? I would have thought it would have the same problems with the oxide as other electronic solders. No?

Thanks jer, that's the one I remembered. Unfortunately I don't think it's applicable to thin foils. I fear the mechanical scrubbing step would beat them up too much.

I'm a bit lost with the Farnell link but figured I'd make yet another attempt to find a promising source of solder for aluminum. KappAloy9 popped up but I haven't yet found a way to buy it.

Is that conventional Ersin multicore? I would have thought it would have the same problems with the oxide as other electronic solders. No?

The multicore solder works like a charm on foil!

The multicore solder works like a charm on foil!

Good to know. I'll give it a try. I can't quite tell from the photo you posted which variety of Ersin solder you've had success with. My searching suggests there are multiple varieties. Does it say anything that distinguishes it on the label?

I never use solder just a penny washer, works every time and lasts for years.

I may be doing something closer to the Analysis Epsilon approach than running a single conductor over the whole diaphragm. I'd rather be able to make solder connections at the top and bottom of each conductor than rely on tons of mechanical connections.

Thanks, all.

Few

Last edited:

I haven't got it right here at the moment but at my workshop.

But from one of our companies here in Sweden You get this information...

The major important thing here is the fluss in the core that is ERSIN 362.

https://www.elfa.se/elfa3~se_sv/elfa/init.do?query=ersin#filter=0:manu|0|:89738|4|466938,;

But from one of our companies here in Sweden You get this information...

The major important thing here is the fluss in the core that is ERSIN 362.

https://www.elfa.se/elfa3~se_sv/elfa/init.do?query=ersin#filter=0:manu|0|:89738|4|466938,;

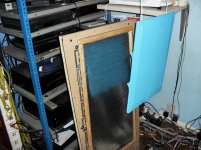

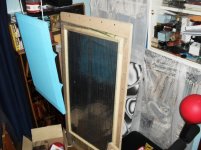

next project headphones 2 designs

The blue ones are my latest rebuilds, 7.1 Ohms. Then headphones 2 layouts see which is the best!

The blue ones are my latest rebuilds, 7.1 Ohms. Then headphones 2 layouts see which is the best!

Attachments

some more pics of rebuilds

A epsilon layout design using 5 separate layouts on 1 diaphragm, using 40 x 25 x 10 mm ferrites.

A epsilon layout design using 5 separate layouts on 1 diaphragm, using 40 x 25 x 10 mm ferrites.

Attachments

-

SAM_0205.JPG769.4 KB · Views: 109

SAM_0205.JPG769.4 KB · Views: 109 -

SAM_0204.JPG726 KB · Views: 94

SAM_0204.JPG726 KB · Views: 94 -

SAM_0203.JPG767.7 KB · Views: 97

SAM_0203.JPG767.7 KB · Views: 97 -

SAM_0202.JPG752.2 KB · Views: 59

SAM_0202.JPG752.2 KB · Views: 59 -

SAM_0201.JPG745.7 KB · Views: 67

SAM_0201.JPG745.7 KB · Views: 67 -

SAM_0200.JPG719.2 KB · Views: 75

SAM_0200.JPG719.2 KB · Views: 75 -

SAM_0198.JPG711.5 KB · Views: 83

SAM_0198.JPG711.5 KB · Views: 83 -

SAM_0195.JPG690.9 KB · Views: 89

SAM_0195.JPG690.9 KB · Views: 89 -

SAM_0197.JPG766.2 KB · Views: 83

SAM_0197.JPG766.2 KB · Views: 83 -

SAM_0196.JPG742.8 KB · Views: 114

SAM_0196.JPG742.8 KB · Views: 114

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- analysis epsilon