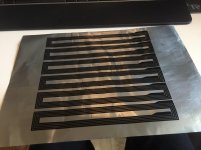

Ok i used my laminated foil for coils now, the foil i used was also a sample in this thickness.

so serg if you want some decent coils. look at these i did not try yet how small i can make them , i do know that 0.3 - 0.35 is somewhat the smallest gap in between the windings before the ink smears just enough to not etch nicely.

max size 280-290 mm so you would need 2 if you would want to use them. just glue them on with a glue that adheres to polyesther, use the flux to solder the leads to and to solder a bridge from one coil to the other

just my 2 cents i got the nomex is ç my previous attempt to get soem control of dispersion in this weird design failed. it keeps being a weird polar response, i do think it is the nature of the beast. but still i will try to make a nomex version

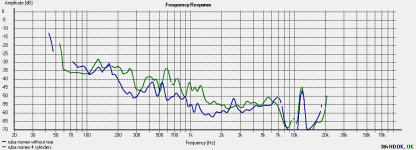

i got the nomex is ç my previous attempt to get soem control of dispersion in this weird design failed. it keeps being a weird polar response, i do think it is the nature of the beast. but still i will try to make a nomex version  starting with a normal rubanoide with 4 cylinders. although i am going to be annoyed by the dip and peak around 1 khz or so. even after damping it is visible. might not hear it but it is there !

starting with a normal rubanoide with 4 cylinders. although i am going to be annoyed by the dip and peak around 1 khz or so. even after damping it is visible. might not hear it but it is there !

so serg if you want some decent coils. look at these i did not try yet how small i can make them , i do know that 0.3 - 0.35 is somewhat the smallest gap in between the windings before the ink smears just enough to not etch nicely.

max size 280-290 mm so you would need 2 if you would want to use them. just glue them on with a glue that adheres to polyesther, use the flux to solder the leads to and to solder a bridge from one coil to the other

just my 2 cents

Attachments

Interesting my friend. Very interesting coils you got there. Still, i have to wait too long for the coils to arrive. I will try my best to make them by hand as neat as i can.

I think that before you stick the coil to the cils you have to laminate the coil on both sides to transfer to both of them the same quantity of sound .

I have tried smaller membr also and seen that the bigger/taller the cils the smaller the dip is and it moves to a lower region of the spectrum. It will be interesting to see a "Janus 70" respomse..

Cheers

Sergiu

I think that before you stick the coil to the cils you have to laminate the coil on both sides to transfer to both of them the same quantity of sound .

I have tried smaller membr also and seen that the bigger/taller the cils the smaller the dip is and it moves to a lower region of the spectrum. It will be interesting to see a "Janus 70" respomse..

Cheers

Sergiu

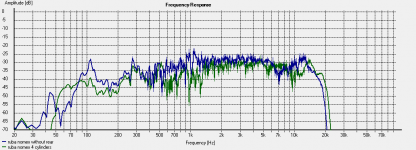

here a small test. goal to see the real diference

4 cylinders vs my open back 2 cylinder design.

same coil same nomex 410 0.17mm same motor same size.

first picture freq response second distortion

looks like 2 cylinders wins. i though i might have some disrtotion because of the fact both sides are not the same. but apparently the fact that 4 cylinders are working in tandem and sharing the space between them destroys more then it gains. no output no nothing except more distortion and less output even.

to minimize distortion , mostly present in the lower end of the sprctrum it would eb nice to have 2 complete ones above each other with one turned around and out of phase. so the distortion of the uneven balanced motor will cancel each other out. like they do in open baflle every now and then. another aspect is you could let the top one play fullrange and the bottom one only 500 and lower. this will increase low end output witch helps with the distortion. there is no need for more gain above 1khz

now i listen to them with some tweaks and a gain of 9 dB down 500 hz it is playing fullrange from 65 hz

it is playing fullrange from 65 hz  cant blast ofcourse and distortion down low is not where i would like to have it

cant blast ofcourse and distortion down low is not where i would like to have it  but casual listening he sounds pretty funny

but casual listening he sounds pretty funny  oef i noticed my coil being 1.6 ohm

oef i noticed my coil being 1.6 ohm  poor amplifier

poor amplifier

4 cylinders vs my open back 2 cylinder design.

same coil same nomex 410 0.17mm same motor same size.

first picture freq response second distortion

looks like 2 cylinders wins. i though i might have some disrtotion because of the fact both sides are not the same. but apparently the fact that 4 cylinders are working in tandem and sharing the space between them destroys more then it gains. no output no nothing except more distortion and less output even.

to minimize distortion , mostly present in the lower end of the sprctrum it would eb nice to have 2 complete ones above each other with one turned around and out of phase. so the distortion of the uneven balanced motor will cancel each other out. like they do in open baflle every now and then. another aspect is you could let the top one play fullrange and the bottom one only 500 and lower. this will increase low end output witch helps with the distortion. there is no need for more gain above 1khz

now i listen to them with some tweaks and a gain of 9 dB down 500 hz

Attachments

Last edited:

Interesting my friend. Very interesting coils you got there. Still, i have to wait too long for the coils to arrive. I will try my best to make them by hand as neat as i can.

I think that before you stick the coil to the cils you have to laminate the coil on both sides to transfer to both of them the same quantity of sound .

I have tried smaller membr also and seen that the bigger/taller the cils the smaller the dip is and it moves to a lower region of the spectrum. It will be interesting to see a "Janus 70" respomse..

Cheers

Sergiu

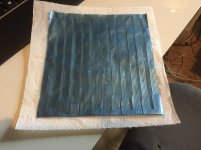

uh yeah you have to sandwich the coils within the paper. since you use 2 of them above each other its simple in series and your ready to rock. good thing is the coils is shielded from the metal may it ever hits it you wont short your amp and the rest.

i do this: paper coil paper. just impregnate the paper with epoxy, put the coil on solder leads, epoxy them and add the last paper. put it in a press to dry. i use a heat gun to get the epoxy viscosity down and brush it out while heated. this ensures it is getting soaked, and speeds up the dry time after.

Last edited:

Here is it playing some fullrange, you can hear the sort of compressed sound when over driven

https://youtu.be/eR3QRD2b6lM

https://youtu.be/eR3QRD2b6lM

That's very nice my friend. I love it. I wanted to buy a heat gun but wasnt shure if i needed it or not. I will see about it next month.

Considering the fact that your ruban is smaller i would use a thinner foil to get high impedance. Almost 2 ohms is not good for any amp. I made today two coils with 1mm with per trace and same for the space between them and got 15ohms. I can use thicker foil but at my final ruban. I just wanted to point out that if i get 15ohm from 50 cm coil you can get 7-8ohm dc with ease at 30 cm.

These two new rubans of mine will be bonded tomorrow and tested next week. One of them is covered totally in laqueur and the other 70% wax and 30%laq. Cant wait to see the results.

Can you post a pic so that i can see how much and how close to the coil you'ed cutted?

I love how your nomex ruban sounds. How would you compare it with paper?

Cheers

Sergiu

Considering the fact that your ruban is smaller i would use a thinner foil to get high impedance. Almost 2 ohms is not good for any amp. I made today two coils with 1mm with per trace and same for the space between them and got 15ohms. I can use thicker foil but at my final ruban. I just wanted to point out that if i get 15ohm from 50 cm coil you can get 7-8ohm dc with ease at 30 cm.

These two new rubans of mine will be bonded tomorrow and tested next week. One of them is covered totally in laqueur and the other 70% wax and 30%laq. Cant wait to see the results.

Can you post a pic so that i can see how much and how close to the coil you'ed cutted?

I love how your nomex ruban sounds. How would you compare it with paper?

Cheers

Sergiu

it sounds the same as paper, about the coil, i am gone make a overhung coil and slightly reduce trace width, so i can fit in few more winding and get higher impedance. my goal is 4 ohms, since there is no reason to make a 8ohm version , most amps can handle 4 ohms with ease. i also got thinner foil if needed.

as for now there is 1 cm sticking out from the coil former outwards on the back of the ruba. since my elastic bands are there i must have some meat. but i will cut of the middle part, it reduces weight and increases high end.

as for now there is 1 cm sticking out from the coil former outwards on the back of the ruba. since my elastic bands are there i must have some meat. but i will cut of the middle part, it reduces weight and increases high end.

Very interesting. I would not sugest overhung unless you have rounded edges steel plates for your motor. I tried overhung with this new magnetic motor (with straight edges) and i have lost some dB's and the sound isnt that open and relaxed anymore...  just 1:1 coil to plates ratio sounds best for the straight edges, if you go underhung the voices becomes thin and edgy (dont know why).

just 1:1 coil to plates ratio sounds best for the straight edges, if you go underhung the voices becomes thin and edgy (dont know why).

I also compared 4ohms vs 8ohms coils with 1:1 ratio and my conclusion was that the voice on the 8 ohm sounded more round, more relaxed, and had abit more bottom end (bass) on the same jlh 69@10w; an amp wich can eat these impedances on breakfast. I throw a 2.1 ohm dc coil at this tiny amp and didnt show a sweat.

After you cut the back and leave that 1cm just for the hinges, does the ruba has the same sound signature, or the voices gets thin and you have allot of hights?

I ask this because in case of filtering the ruba down to 200-300hz it has to reproduce the voices with very high fidelity and very high accuracy to be able to make a good pair with the bass...

I also compared 4ohms vs 8ohms coils with 1:1 ratio and my conclusion was that the voice on the 8 ohm sounded more round, more relaxed, and had abit more bottom end (bass) on the same jlh 69@10w; an amp wich can eat these impedances on breakfast. I throw a 2.1 ohm dc coil at this tiny amp and didnt show a sweat.

After you cut the back and leave that 1cm just for the hinges, does the ruba has the same sound signature, or the voices gets thin and you have allot of hights?

I ask this because in case of filtering the ruba down to 200-300hz it has to reproduce the voices with very high fidelity and very high accuracy to be able to make a good pair with the bass...

My smaller one never reached 200 without a form of eq, so I don't know , you can see it in the measurement , there is not less Bas it even fills in the gap under 1. kHz witch the true rubanoid created a big nasty dip. As you can hear in the video there is Bas's if I add , this thing is to small to play full range and move enough air as it is. But it can reproduce it but not as efficient

Last edited:

I like the ideea of the cutted back. The nomex seems to have the, at the end, the same propreties as the waxed paper: the nomex softens and bends when gets very wet and on the other side the paper bends and softens when waxed and remains with the desired form after the wax dryes only the nomex its definetly harder.

The waxing inpregnation procedure that i use is very simple: i impregnate the paper with laq only on the sides where the coil will be +1cm and add more laq only on the front side (about 5cm on each half cilinder) then i light a candle wax (parafine to mantain the collor of the paper) and pour the dots of melted wax on the paper and spread it with a piece of plastic and a hair drier till it inpregnates the paper.

Another aspect that i found after waxing the paper is that the paper doesnt wrinkle any more when bended hard.

Anyway i hope that wax is a good solution for paper and sounds good. Cant say nothing till next week when i hear it....

My friend i would sugest to use a bigger vers of ruban and to achieve this you cand do as i did: reinforce the the magnetic motor with thick U shaped steel and steel rods. The bigger vers will not dissapoint you believe me. I tried smaller membranes and bigger one but always loved the bigger membranes sound reproduction.

As for the buzzing i can barelly hear it. I watched the video with my phone.

I think that if you strech the cils too much to avoid the "peak" phenomena you will loose the wide dispersion of this beast and at the end you will have a 'ru ba bas'.

The pic atached bellow is the only one i can found this close. It seems that this ruba bas is composed by two regular rubas arranged in the same plane with a flat membr as you did a bass ruba last year.

Cheers

Sergiu

Attachments

Hi serg, well the biggest beneifit of the nomex is it is not paper. so when i make holes and attach the elastic bands. they wont rupture ever !! you cant tear the stuff. you need a very sharp knife to cut it ! so you can pull on these strings prety hard. i can even determene the resonance by pulling them. i tried 40 hZ 50hZ and 65 Hz @ 40 hZ the excursion is a bit to big for the poor thing. i might need to re draw the coils for that.

By the way watch the movie on a PC and good speakers with low end and you will notice how sickly low they can go.... well 45 Hz if you force them

if you force them

By the way watch the movie on a PC and good speakers with low end and you will notice how sickly low they can go.... well 45 Hz

Now i see. Hohoho. Just listened yesterday on pc. Pretty impressive. It looks that with nomex you can even make a bass ruban like the one from the pic posted above.

Nice stuff.

Unfortunatelly i didnt have time to bond mines this weekend so i will bond them today and will listen to them tomorrow.

Cheers

Sergiu

Nice stuff.

Unfortunatelly i didnt have time to bond mines this weekend so i will bond them today and will listen to them tomorrow.

Cheers

Sergiu

Well the bass is due to the membrane being made of foamboard, in a video of the ruba with all the colors I mentioned the paper is flapping at low frequency, there i sugested to use some stiffer material like foam board. When moulded in a 1/3 cylinder it seems to work, after some tweaking I got the 3rd harmonic distortion down 15-20 dB in the lower range.

I am. It sure if the gain of 11 dB from 350 now is needed because of the open bAfle design or the driver it self, creating a bAfle for such low frequencies need more then just 2 boards. And the design does not let itself being put in a box to cancel the baffle loss, also the box might be insanely big, depending on the ts parameters. So my best bet is to increase surface area. Thursday I will ge me some bigger metal bars to creat a version 2,5 times as big with the use of 2 coils above eCh other.

I also did some modeling in FEM an I noticed that using thinner bars did almost nothing to the field strength when using weak magnets. I also noticed that using thicker metal bars also lose almost nothing in field strength. That's good to know since I can then create a smaller coil that can ride into a 12 mm even magnetic field , when the coil is 6 mm wide it will be an underhung construction that has a linear x max of 3 mm to either direction. Sounds cool but if it all works out ?who knows, proof is in making a mess and see

but if it all works out ?who knows, proof is in making a mess and see

I am. It sure if the gain of 11 dB from 350 now is needed because of the open bAfle design or the driver it self, creating a bAfle for such low frequencies need more then just 2 boards. And the design does not let itself being put in a box to cancel the baffle loss, also the box might be insanely big, depending on the ts parameters. So my best bet is to increase surface area. Thursday I will ge me some bigger metal bars to creat a version 2,5 times as big with the use of 2 coils above eCh other.

I also did some modeling in FEM an I noticed that using thinner bars did almost nothing to the field strength when using weak magnets. I also noticed that using thicker metal bars also lose almost nothing in field strength. That's good to know since I can then create a smaller coil that can ride into a 12 mm even magnetic field , when the coil is 6 mm wide it will be an underhung construction that has a linear x max of 3 mm to either direction. Sounds cool

Last edited:

If i remember well in one of my old posts you will find a measurement for "big cuts" where i cutted allot of big holes in the back of the membrane (something aprox similar to your "back cut" vers). I did not cuted all the back because i wanted to to keep the membrane centered.

The conclusion was that this version had in measurements a bigger 1khz gap +another one near it wich where giving a thinner voice and insanelly high level of hights when listening to it compared to the smaller cuts from the classic version wich where very ok at that time.

My conclusion about femm is that it sucks. My opinion is that it doesnt quite simulate that good. We have allot of variables here. There is no explanation why the strenght in the gap almost doubles at 3mm gap (10mm+3mm gap+10mm=23mm) and does almost nothing when i aproach the magnets more to 20mm (8+4mm gap+8) . It makes no sense. These things needs a dedicated measuring tool. I doubt the sims are ok.

The conclusion was that this version had in measurements a bigger 1khz gap +another one near it wich where giving a thinner voice and insanelly high level of hights when listening to it compared to the smaller cuts from the classic version wich where very ok at that time.

My conclusion about femm is that it sucks. My opinion is that it doesnt quite simulate that good. We have allot of variables here. There is no explanation why the strenght in the gap almost doubles at 3mm gap (10mm+3mm gap+10mm=23mm) and does almost nothing when i aproach the magnets more to 20mm (8+4mm gap+8) . It makes no sense. These things needs a dedicated measuring tool. I doubt the sims are ok.

Last edited:

well big companys use FEMM, im pretty sure it is correct. about the Nomex if we know what thickness we would like they are willing to send me some offcut. but it all depend on the width we need, as of now i only use it as coil former so i dont need a huge width. but i will first try the 0.13. since i used 0.17 so far.

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind