well without doing a structure analysis I cant say for sure. My gut tells me that you may be beyond point of diminished return here. Beam height is where the stiffness is. adding a bunch of material ,reguardless of shape, to a given space really doesnt add a lot of stifness and you have a serious amount of force to overcome.

I supose you can give it a shot and see BUT if I were you I would try to find or make some U channel to fit those magnets into. Ive even made such a thing from wood in past.

The magnet pull force is somthing like 1/ distance to the 4th power. As they get close to each other the force really takes off.

I supose you can give it a shot and see BUT if I were you I would try to find or make some U channel to fit those magnets into. Ive even made such a thing from wood in past.

The magnet pull force is somthing like 1/ distance to the 4th power. As they get close to each other the force really takes off.

Attachments

Last edited:

new principle speaker

Hi, all

I am making new principle speaker now.

ultrasonic non-directional speaker

please tell me your comment.

thank you,

Hi, all

I am making new principle speaker now.

ultrasonic non-directional speaker

please tell me your comment.

thank you,

Hi, all

I am making new principle speaker now.

ultrasonic non-directional speaker

please tell me your comment.

thank you,

Very interesting ! tell us more

Hi,

Thank you for comment.

I am kit maker. I am making parametric speaker kit from 2008.

in this few month, I develop high quality sound parametric speaker.

I could make good sound parametric speaker one month ago.

I had heard the sound of parametric speaker long time every days.

I noticed a sound to hear voices of the vocals very well.

traditional speaker have cone, magnet, dumper. these components produce sound including distortion. sounds mixes on corn. this is limitation of traditional speaker.

but principle of parametric speaker is non-linear characteristic of air. there is no limitation such as cone and magnet. The separation of the sound source is very good. So vocal is heard vividly..

But this method can not produce under about 100Hz. low frequency sound become distortion. I think subwoofer is needed for lower frequency.

also there is problem that is headache when hearing supersonic at long time. I make long tube for delete ultrasound. directional sound is gone. but good audible sound is left.

Thank you for comment.

I am kit maker. I am making parametric speaker kit from 2008.

in this few month, I develop high quality sound parametric speaker.

I could make good sound parametric speaker one month ago.

I had heard the sound of parametric speaker long time every days.

I noticed a sound to hear voices of the vocals very well.

traditional speaker have cone, magnet, dumper. these components produce sound including distortion. sounds mixes on corn. this is limitation of traditional speaker.

but principle of parametric speaker is non-linear characteristic of air. there is no limitation such as cone and magnet. The separation of the sound source is very good. So vocal is heard vividly..

But this method can not produce under about 100Hz. low frequency sound become distortion. I think subwoofer is needed for lower frequency.

also there is problem that is headache when hearing supersonic at long time. I make long tube for delete ultrasound. directional sound is gone. but good audible sound is left.

back to basics

sergiu, i hope you are solving your magnet bar stiffness. magnets are strong, and it must be hard to keep steel straight over such a long distance if the bars are narrower....

with my own speakers, i have finally given up on 3 part membranes and 1 part membranes and have made some "normal" 2 part rubanoids. they are great!!!

i have made one in carbon fibre and one in orange paper to compare. they sound very similar weirdly, the carbon fibre is a little louder, and the paper sounds warmer and softer. i like the paper better, probably because it is orange.

i used copper coils i wound from 0.2mm enamelled wire on formers i take out after setting with epoxy. pretty light, and easy for me.

the adjustment for the membrane position is easy using a simple setup with screws and clamping the edge of the membrane.

these are crossed over at 200hz to woofers below. at first they sounded weird to me - so strangely open, a little sibilance in female vocals (mostly gone now, or i am used to it!), and so much space. very airy. and clear. it is a very different sort of sound (reminds me when i first listened to electrostatic headphones), and now i am used to it after an hour, i like it so much i am going to build 4 proper panels and have 2 per side like is sometimes done....

you can hear the instruments playing, and the player's breath and fingers. it is very involving. i am listening more to the music and less to the speaker, and this is what i want - after i have made these i want to have a hobby of listening to music, not building speakers. : )

thanks again, especially to sergiu and wrine, you generous bastards. you guys are inspiring with your perseverance and telling us all your thoughts and making.... it inspired me to make these and have fun. : )

sergiu, i hope you are solving your magnet bar stiffness. magnets are strong, and it must be hard to keep steel straight over such a long distance if the bars are narrower....

with my own speakers, i have finally given up on 3 part membranes and 1 part membranes and have made some "normal" 2 part rubanoids. they are great!!!

i have made one in carbon fibre and one in orange paper to compare. they sound very similar weirdly, the carbon fibre is a little louder, and the paper sounds warmer and softer. i like the paper better, probably because it is orange.

i used copper coils i wound from 0.2mm enamelled wire on formers i take out after setting with epoxy. pretty light, and easy for me.

the adjustment for the membrane position is easy using a simple setup with screws and clamping the edge of the membrane.

these are crossed over at 200hz to woofers below. at first they sounded weird to me - so strangely open, a little sibilance in female vocals (mostly gone now, or i am used to it!), and so much space. very airy. and clear. it is a very different sort of sound (reminds me when i first listened to electrostatic headphones), and now i am used to it after an hour, i like it so much i am going to build 4 proper panels and have 2 per side like is sometimes done....

you can hear the instruments playing, and the player's breath and fingers. it is very involving. i am listening more to the music and less to the speaker, and this is what i want - after i have made these i want to have a hobby of listening to music, not building speakers. : )

thanks again, especially to sergiu and wrine, you generous bastards. you guys are inspiring with your perseverance and telling us all your thoughts and making.... it inspired me to make these and have fun. : )

Last edited:

Hei Orangealpaca,

I have told you my ideeas about the sibilance and confusing sound when playing cmplex music on the other thread of yours .

.

I'm glad you like these speakers and enjoy the sound.

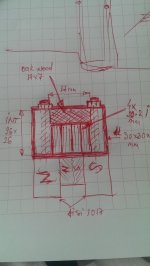

I have leaved the ideea of all Al tensionning frame, and now trying reinforcing with Al and oak wood as spacers and magnetic field insulators and 5mm U shaped steel. Will try these things this week.. i just finished drilling the 5mm steel for just one ruban in a couple of hours yesterday... Its very hard to drill a hole straight without proper tools .

.

I have to find a sollution for my bending issue.

Now i have the same prob as you: i love the sound comming from these speakers but cannot hear them anymore. Believe me once you hear them singing its hard to not hear that sound again. In my case its a frustrating situation especially because my wife heard them allot of times a couple of monts ago and now calls my old sealed speakers garbage and wants to hear the rubans again and fast.

"thanks again, especially to sergiu and wrine, you generous bastards. you guys are inspiring with your perseverance and telling us all your thoughts and making.... it inspired me to make these and have fun. : )"

Hehe

I'm glad we inspired you and hope we inspire others to come with new ideeas and excell where we did wrong.

I'm glad we inspired you and hope we inspire others to come with new ideeas and excell where we did wrong.

I'm still searching for a 120gr/sqm (rice, cotton, banana pulp, washy paper or other exotics) to play with but found none; maybe others will find these things and test them and post here some impressions and measurements.

Till then i hope that others will build this speaker at least as it is and love it as we did.

Cheers

Sergiu

I have told you my ideeas about the sibilance and confusing sound when playing cmplex music on the other thread of yours

I'm glad you like these speakers and enjoy the sound.

I have leaved the ideea of all Al tensionning frame, and now trying reinforcing with Al and oak wood as spacers and magnetic field insulators and 5mm U shaped steel. Will try these things this week.. i just finished drilling the 5mm steel for just one ruban in a couple of hours yesterday... Its very hard to drill a hole straight without proper tools

I have to find a sollution for my bending issue.

Now i have the same prob as you: i love the sound comming from these speakers but cannot hear them anymore. Believe me once you hear them singing its hard to not hear that sound again. In my case its a frustrating situation especially because my wife heard them allot of times a couple of monts ago and now calls my old sealed speakers garbage and wants to hear the rubans again and fast.

"thanks again, especially to sergiu and wrine, you generous bastards. you guys are inspiring with your perseverance and telling us all your thoughts and making.... it inspired me to make these and have fun. : )"

Hehe

I'm still searching for a 120gr/sqm (rice, cotton, banana pulp, washy paper or other exotics) to play with but found none; maybe others will find these things and test them and post here some impressions and measurements.

Till then i hope that others will build this speaker at least as it is and love it as we did.

Cheers

Sergiu

Nice work !!!! Glad you enjoy them !! But please do measure them it's all to easy to ge used to way to much top end and going back is hard. It also contributes to the feeling of detailed sound although you are listening to an overkill of details. I don't want to be a party pooper just try to not let you fall for the same thing I fell for couple of years back with Esl's unfiltered use gave me so much detailed but when measured you see why and when listening to a straight curve was boring

But well done anyways !!! Makes my hands itch again stop it !!!! I'm not finished yet with other projects !

But well done anyways !!! Makes my hands itch again stop it !!!! I'm not finished yet with other projects !

Hello my friend Wrine!

I'm back, and this time with good news. It seems that my ruban needed a different aproach, this time with U shape 5mm thick steel. It is a total succes! Now the plates doesnt bend anymore and the distance between the plates and the reinforcement is sufficient so that they dont get magnetised. I need to add some insulators to the screws because they are made from iron now instead of olc steel...

The magnetic gap is 4mm now instead of 3mm as before. The reinforcement resists at 3mm gap (tested) but i need to eliminate the square Al pipes from the top of the U frame, thing that i dont want. The 4 mm gap seems more convenient when centering the coils so i'll leave it as it is. I need to drill the steel for the other channel but will leave this for tomorrow.

Bellow i atached some pics with the results (4mm gap).

Cheers

Sergiu

I'm back, and this time with good news. It seems that my ruban needed a different aproach, this time with U shape 5mm thick steel. It is a total succes! Now the plates doesnt bend anymore and the distance between the plates and the reinforcement is sufficient so that they dont get magnetised. I need to add some insulators to the screws because they are made from iron now instead of olc steel...

The magnetic gap is 4mm now instead of 3mm as before. The reinforcement resists at 3mm gap (tested) but i need to eliminate the square Al pipes from the top of the U frame, thing that i dont want. The 4 mm gap seems more convenient when centering the coils so i'll leave it as it is. I need to drill the steel for the other channel but will leave this for tomorrow.

Bellow i atached some pics with the results (4mm gap).

Cheers

Sergiu

Attachments

Just to make things even more interesting... It took me a couple of hours to saw the special treated laminated oak. Cant wait to test them tomorrow and compare them, and measure. It seems that hard wood is very good too for spacers. The gap remained the same as yesterday when assembled.

Cheers

Sergiu

Cheers

Sergiu

Attachments

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind