I have some experience with dhts in line and power applications and a filament CCS makes life considerably easier ime. I previously used Ronan style filament regulators which worked well. I'm currently using Rod Coleman's filament regulator boards (CCS and gyrator) to heat the GM70s in my amps, quite happy with their performance and they're reasonably priced. I do use LT1084 as pre-regulators which can be problematic because of the behavior of their current limiting as well as the sorts of issues Frank mentions. Keeping the noise out of the amplifier with 100dB + efficient speakers that get down into the low 30s is a serious problem.

Hi,

Yep.

That's the other end of the stick, errr, spectrum.

Both extremes are "problematic" but also o so educational.

Hence my interest in low noise, low interference (in every sense of the word) heater supplies for idht valves as well.

Rod et all, you have yourselves a market niche.

Best,

Keeping the noise out of the amplifier with 100dB + efficient speakers that get down into the low 30s is a serious problem.

Yep.

That's the other end of the stick, errr, spectrum.

Both extremes are "problematic" but also o so educational.

Hence my interest in low noise, low interference (in every sense of the word) heater supplies for idht valves as well.

Rod et all, you have yourselves a market niche.

Best,

Last edited:

One should keep in mind, that there are different sounding 845 examples, as well as GM70 examples (various manufacturers and plate materials).

My experience, is that trash priced GM70 sound also trash. But those old examples by Foton plant, and also copper plate and "metal" plate, sound very good.

My experience, is that trash priced GM70 sound also trash. But those old examples by Foton plant, and also copper plate and "metal" plate, sound very good.

I was not aware that there are so many different copper versions...which is your favourite ? I saw only versions from the 80s..

on the 845: I have found all kind of nice reviews on the metal plate, especially the Shuguang nobleman etc when kt comes to chinese. Interesting is, that in 2014 a significant update/upgrade took place, but I did not find a lot about user reviews: Shuguang 845C Iron plate, factory matched PAIR - HiFi Triodes,

" upgrade 05-2014

845C Iron Plate now with increased 95 watts max. plate dissipation

the socket is made out of pure copper. beside the great screening the copper does tend to oxidate to a vintage appearance which is normal

The new anode has been increased in strength and length to handle more power with ease compared to the earlier versions.

Toshiba specially-made thorium tungsten cathode vacuum tube 845 is with more anode dissipation power. The cathode material with very strong electron emitting capacity helps to avoid distortion with a strong signal inputting. The distance between anode and grid leading wires has been increased to 35mm which improves the insulation greatly and at the same time reduces the medium loss of stem glass to resolve the problem of stem blown and air leak from stem. The new designed tubes 845B/845C are evacuated supremely for a long lifespan and stable performance. The tube is based with a pure copper base which is beautiful and has very good shelter to outside electricity field.

To sum up, the vacuum tube 845B/845C has an outstanding performance both in stability and sound."

on the 845: I have found all kind of nice reviews on the metal plate, especially the Shuguang nobleman etc when kt comes to chinese. Interesting is, that in 2014 a significant update/upgrade took place, but I did not find a lot about user reviews: Shuguang 845C Iron plate, factory matched PAIR - HiFi Triodes,

" upgrade 05-2014

845C Iron Plate now with increased 95 watts max. plate dissipation

the socket is made out of pure copper. beside the great screening the copper does tend to oxidate to a vintage appearance which is normal

The new anode has been increased in strength and length to handle more power with ease compared to the earlier versions.

Toshiba specially-made thorium tungsten cathode vacuum tube 845 is with more anode dissipation power. The cathode material with very strong electron emitting capacity helps to avoid distortion with a strong signal inputting. The distance between anode and grid leading wires has been increased to 35mm which improves the insulation greatly and at the same time reduces the medium loss of stem glass to resolve the problem of stem blown and air leak from stem. The new designed tubes 845B/845C are evacuated supremely for a long lifespan and stable performance. The tube is based with a pure copper base which is beautiful and has very good shelter to outside electricity field.

To sum up, the vacuum tube 845B/845C has an outstanding performance both in stability and sound."

Stay away from Chinese sockets they do not stand up much heat, they are not indicated to 6C33 (80W heat) much less for a huge GM70 (180W heat).I am thinking of making a GM70 push pull amps.

Are the Chinese sockets OK?

Thanks

Phil

Sometimes on ebay there is some Polish Teflon GM70 sockets, in last case I have a pair I can send to you.

Fullrangeman how many GM70 amps you made??? i made 3 SE and the only one with teflon socket made me swear, teflon just disintegrate when pin move and one PP GM70. these amps run every day from years and never get problems

of course could have different stuff. i take sockets from german bay store "classic_component". so they sell good china quality

of course could have different stuff. i take sockets from german bay store "classic_component". so they sell good china quality

Last edited by a moderator:

Maybe you live in a cold area or its chinese Teflon too, over the years I have read many reports of these bad sockets they all use this awful claw system:Fullrangeman how many GM70 amps you made??? <snip>

My current SE 6C33 amp used chinese sockets from Tube Depot after 1 winter and 1 summer I had to change it due loose pins and false contacts, but it dont compare to your first hand builder experience. However here is not properly a cold area, also these claw pins stress the tube pins/glass seal which not good of course.

This below is an Teflon socket from Poland used by Marcin SE GM70:

This other below also Teflon are from your nice construction SE GM70 amp:

http://monsite.woopic.com/383/p/claudiomas/img/10aaaee3eb6079c491dd6f44ed94f2bb.jpg

well should be careful with teflon sockets brass pins screwed can destroy teflon, GM70 glass bulb its far away from pins so they do not become very hot like 6C33. i think you can solder 1.3 inch /3.5cm GM70 base on 6C33 !!! img from bay urss store , i do not support him, just for check construction

Attachments

If the socket pins are spring loaded no problem. If not, you can destroy teflon/ceramic and the tube pins! I´m using following ones and finally found manufacturer for cheap teflon manufacturing:

KONTEC - Hochstrombuchse HLB

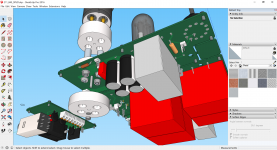

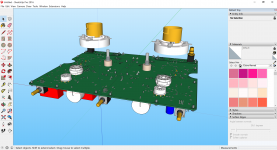

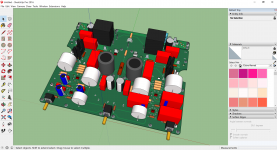

First some prototype before proposing GB in 2018.

JP

KONTEC - Hochstrombuchse HLB

First some prototype before proposing GB in 2018.

JP

i do not like teflon sockets for big triodes, mechanically too fragile. look UX4 for 866A and four pin GM70, if you do not solder the screws can get loose, so soldering or fastening metal in teflon its very critical. no heavy duty, so i prefer ceramic, any way these large base tubes do not get very hot a the pins

zoom from larger img.:

zoom from larger img.:

Attachments

For the 833C in my Midlife Crisis amps I could not find a sturdy socket that looked the way I wanted, so I made my own from teflon bar stock and Home Depot electrical fittings. Holds the tube very firmly and fits snugly inside the pyrex cylinder enclosing the tube.

Attachments

Last edited:

Don´t stress mechanically teflon. Teflon is only isolator. Attached a view of what I´m thinking about but never found cheap manufacturer (and I don´t have own CNC machine).

In my last 12BH7/7027/845/LL1691 I´m using standard Jumbo ceramic socket.

JP

In my last 12BH7/7027/845/LL1691 I´m using standard Jumbo ceramic socket.

JP

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- 845 vs GM70