… unvented cone… the vent..

Scott, that is contradictory. If the drivers have a vent — front or back — they are vented.

dave

The shiny bit is a plastic phase plug, the dull black ring is foam ring stuck to the cone and between the two in shadow that you can't see, is a gap, there is no dust cap. However what I had in mind is my HiVi M12 woofers Product information:M12 Bass-Midrange

Is that all I am to you?Scott, you are the Eikona man.

No reason why you should haveI knew you had woofers but never knew which ones and never thou much about them.

dave

I measure the OD of the SB23MFCL45-4 right at 9.25". This jives with the datasheet which spec's 234mm or 9.21".

I measure the ID of the schedule 80 10" PVC pipe at 9.5". This jives with the datasheet which spec's 9.492". This is .64" thick PVC!

That's a total gap of .28", or .14" around the sub frame. The guage wire I'm using is .16" thick with insulation. This can be squeezed to fit through the gap.

Today's goal is to continue to wire them, seal them and drill holes in the PVC for 8 speaker terminals. More pics soon.

Happy Holidays!

I measure the ID of the schedule 80 10" PVC pipe at 9.5". This jives with the datasheet which spec's 9.492". This is .64" thick PVC!

That's a total gap of .28", or .14" around the sub frame. The guage wire I'm using is .16" thick with insulation. This can be squeezed to fit through the gap.

Today's goal is to continue to wire them, seal them and drill holes in the PVC for 8 speaker terminals. More pics soon.

Happy Holidays!

Attachments

Last edited:

I gave up trying to seal them for now. It actually might be close enough to not be of much concern? Hopefully, they won't make noise. Very difficult to separate once it's all together. Might have to come up with a 'special tool' to push the 4 driver module out.

Attachments

Those are looking serious.

I have an idea for sealing them. It would take cutting the tubes in half. Later gluing on PVC rings at the ends to bolt them back together. Like the connections you see on large steel plumbing pipe.

That would be useful to gain access to the inner subs for mounting/ sealing them.

Instead of using threaded rod and dropping everything in as one unit I would be open to placing each driver inside individually. I wouldn't exclude the rods from the design, they can be bolted in after subs are placed. The rods would have to be halved. Running them through the sub flanges and new mounting points should add welcome strength.

Essentially you would be creating 2 halves that bolt to together and become 1x4 isobaric tube.

If PVC pipe is available with OD to match your tubes ID, there are the primary sub mounts. How to cut rings comes into question next. Some metal supply houses have band saws that will cut large PVC accurately.

My idea is more involved but will work if the correct sizes of PVC is available to make rings.

I have an idea for sealing them. It would take cutting the tubes in half. Later gluing on PVC rings at the ends to bolt them back together. Like the connections you see on large steel plumbing pipe.

That would be useful to gain access to the inner subs for mounting/ sealing them.

Instead of using threaded rod and dropping everything in as one unit I would be open to placing each driver inside individually. I wouldn't exclude the rods from the design, they can be bolted in after subs are placed. The rods would have to be halved. Running them through the sub flanges and new mounting points should add welcome strength.

Essentially you would be creating 2 halves that bolt to together and become 1x4 isobaric tube.

If PVC pipe is available with OD to match your tubes ID, there are the primary sub mounts. How to cut rings comes into question next. Some metal supply houses have band saws that will cut large PVC accurately.

My idea is more involved but will work if the correct sizes of PVC is available to make rings.

Last edited:

Here's my PVC source. I don't see anything that comes close.

An added note: They currently weigh 106lbs. 52lbs for the drivers, 54lbs for the PVC.

An added note: They currently weigh 106lbs. 52lbs for the drivers, 54lbs for the PVC.

Last edited:

Not giving up on sealing, but I'm aiming for a few listening tests first before disassembling again. I will need to make a special tool for sure. I'm recovering from a slight back injury.

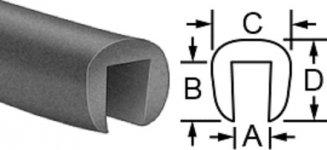

I've been looking at U channel rubber or plastics to run around the outer perimeter of each driver. I've found one made of Neoprene with dimensions that are very close to the .14" gap.

A) 3/8"

B)15/32"

C)11/16"

D)5/8"

B & D are the critical measurements and have a gap of 5/32" or .156". The gap present is .14". Neoprene rubber hopefully has some give to it, and it is oil resistant which is good as I was thinking of adding some lube for install.

I've been looking at U channel rubber or plastics to run around the outer perimeter of each driver. I've found one made of Neoprene with dimensions that are very close to the .14" gap.

A) 3/8"

B)15/32"

C)11/16"

D)5/8"

B & D are the critical measurements and have a gap of 5/32" or .156". The gap present is .14". Neoprene rubber hopefully has some give to it, and it is oil resistant which is good as I was thinking of adding some lube for install.

Attachments

They're wired internally now for operation. Cable management later...

I hope to listen today or tomorrow. I'm just waiting on a new remote for my 7.1amp. The sub output is currently disabled.

Any suggestions for 1st test config?

If you look closely on the 3rd pic, you can tell the PVC is not perfectly round. very close though... Another kink in the sealing equation.

I hope to listen today or tomorrow. I'm just waiting on a new remote for my 7.1amp. The sub output is currently disabled.

Any suggestions for 1st test config?

If you look closely on the 3rd pic, you can tell the PVC is not perfectly round. very close though... Another kink in the sealing equation.

Attachments

Last edited:

I was thinking of a silicone sealantIf you look closely on the 3rd pic, you can tell the PVC is not perfectly round. very close though... Another kink in the sealing equation.

How close are the tolerances between the outer flange and tube?

Maybe an adhesive of some kind in a syringe? Speaker repair adhesive popped into my mind.

The black glue these guys sell for repairs is pretty strong and it dries with a little give, not solid Speaker Repair Adhesive, Dust Caps, Lead-Wires, MI-2000

It should create a tight seal. How good it would be for that application? Having used the stuff I'd say pretty good. Rough up the contact areas before hand.

PCV comes in sheet form chances are you already know. And it can be cut on a CNC. If the right dimension of tube can't be found they can easily cut precise rings from sheet.

Maybe an adhesive of some kind in a syringe? Speaker repair adhesive popped into my mind.

The black glue these guys sell for repairs is pretty strong and it dries with a little give, not solid Speaker Repair Adhesive, Dust Caps, Lead-Wires, MI-2000

It should create a tight seal. How good it would be for that application? Having used the stuff I'd say pretty good. Rough up the contact areas before hand.

PCV comes in sheet form chances are you already know. And it can be cut on a CNC. If the right dimension of tube can't be found they can easily cut precise rings from sheet.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 8 subs and 2 tubes