Well I asked someone to get me the 6J52P and he has already bought it. So I will have something interesting to do !

Does anyone know if the web site Tubes-Store.com - Vacuum tubes, capacitors, nixie tubes, sockets. Wholesale & retail trade. Worldwide shipping. shows different tube pricing depending on the country ( by checking the IP address ) ?

Thanks.

Does anyone know if the web site Tubes-Store.com - Vacuum tubes, capacitors, nixie tubes, sockets. Wholesale & retail trade. Worldwide shipping. shows different tube pricing depending on the country ( by checking the IP address ) ?

Thanks.

thanks!

My amplifier has a 1 meg input impedance. If I ran the 6v6 into a 1:1 instead of the RC circuit on the output, will that be okay? I only thought of this because the best coupling caps are actually in some cases more expensive than a nice transformer.

My amplifier has a 1 meg input impedance. If I ran the 6v6 into a 1:1 instead of the RC circuit on the output, will that be okay? I only thought of this because the best coupling caps are actually in some cases more expensive than a nice transformer.

Last edited:

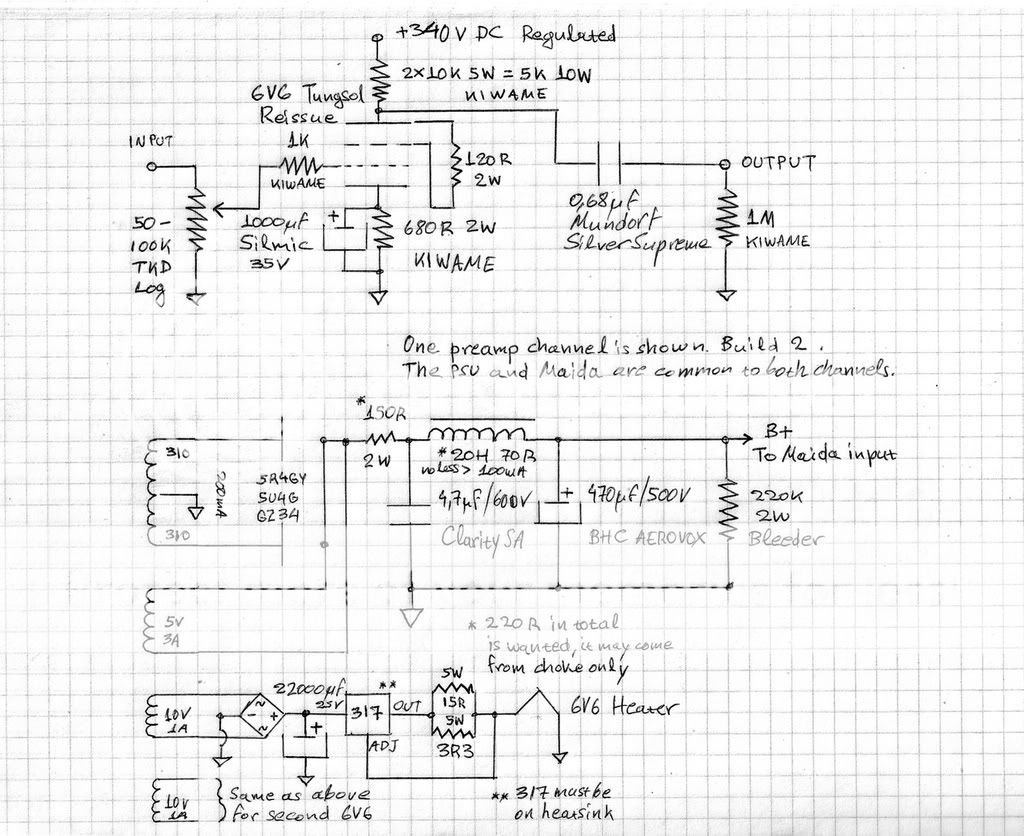

It was always there at the bottom left of the hand drawn original schematic

Hi Salas, no time long see

Can you please explain the CCS circuit for heaters?

I calculate 10V ac X 1.41 ~ 14V less 1.2 V drop across diodes, and Vref from LM317 CCS another 1.2 V. Doesn't that mean we are applying 11.6 V to a 6.3 V heater?

Also we don't know what the variations are in different models/batches, so they may drop more or less voltage at the CCS current. I would think its safer, more consistent to use an LM317 to regulate current not voltage.

Hi Salas, no time long see

Can you please explain the CCS circuit for heaters?

I calculate 10V ac X 1.41 ~ 14V less 1.2 V drop across diodes, and Vref from LM317 CCS another 1.2 V. Doesn't that mean we are applying 11.6 V to a 6.3 V heater?

Also we don't know what the variations are in different models/batches, so they may drop more or less voltage at the CCS current. I would think its safer, more consistent to use an LM317 to regulate current not voltage.

Not Salas here but it is regulating current, not voltage in this config. LM317 needs some 4-5 V overhead for proper regulation.

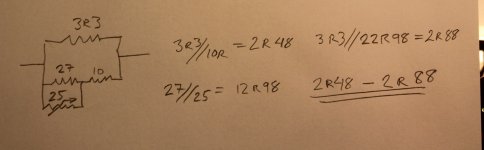

Then, according to my experience, the settings resistor varies alot due to the amount of current needed to drop 6,1 or whatever prefered volts over the heater differs alot on different 6V6 species. I made a variable one.

There is the brands and batches tolerance in actual filament current, then not all LM317 samples have exactly same internal Vref voltage, but 6.3V is nominal with 5.8V-6.8V allowance. Will work with many with no danger, then it can be worked out for preferred tube pair. Better calculate current sourcing with 1.245V LM317 Vref in mind due to it drops with temp. 2-3V Vi-Vo should suffice for non dropping out avoiding some dissipation. We usually allow more Vi (raw DC) for mains variability. But see 2V Vi-Vo as bottom mains spec input DC acceptable.

I like the idea of using a pot here, so if you change the tubes it can be readjusted. Where do you get these high power pots from?

Salas, i remember reading on this forum that 6.3V should not be exceeded, and best to keep it a bit lower for tube life. Anyway, it should be easy with a pot to dial the CCS to get a 6.3V drop across the heaters.

Salas, i remember reading on this forum that 6.3V should not be exceeded, and best to keep it a bit lower for tube life. Anyway, it should be easy with a pot to dial the CCS to get a 6.3V drop across the heaters.

Salas, i remember reading on this forum that 6.3V should not be exceeded, and best to keep it a bit lower for tube life. Anyway, it should be easy with a pot to dial the CCS to get a 6.3V drop across the heaters.

Yes, its good to keep it bit low in the long term but the tubes brands and batches filament current tolerances are unlikely to make that originally shown 317 CCS scheme hit completely out of the ballpark for try outs and destroy some tube or make it work wrongly I meant.

Those are used as inrush limiters in voltage source filament supplies I presume. In the case of CCS filament supplies we see a slow rise of filament voltage though as it heats up. In other words the nominal IF CCS is a current limiter. Will the NTCs still have something to offer?

i saw a comparative study between a constant voltage, constant current, and resistor in the filament circuit of a tube.....http://www.john-a-harper.com/FilamentHeating/

Very nice article that will help members see the different approaches workings better. Thanks.

P.S. I should maybe remind at this point that I did not originally choose the constant current scheme for this preamp on easy warm up grounds but mainly because I liked it better.

P.S. I should maybe remind at this point that I did not originally choose the constant current scheme for this preamp on easy warm up grounds but mainly because I liked it better.

- Home

- Amplifiers

- Tubes / Valves

- 6V6 line preamp