Eldam & others:

Owning or having access to a 3d printer is nice and a great new technology that will evolve over time. Most are small and still fairly expensive. Some people have actually made a working gun using a 3d printer !!!!!

A horn system can get expensive but you can do like I did and buy the drivers and horns/waveguides a piece at a time as your budget allows. I made my mid bass horns and it was the best time/money investment I ever spent in audio. You have to look at this as long term gratification. Buying many different speaker systems over time can be very expensive.

When you look at Physics aspect of speakers NO cone driver can keep up with the speed and control of a good compression driver due to the very low moving mass and powerful motor of the compression driver. Most good compression drivers have flat frequency and impedance curves which makes them easy to drive.

Joe

I would have to disagree that compression drivers sound best in horns. Look at recent work by myself and Weltersys. A cone loaded horn has lower harmonic distortion than a compression driver in the mods mids for same SPL.

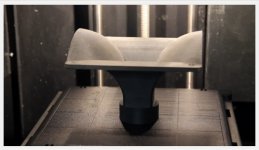

The Stratasys FDM 3D Printer from Eminence with 8" x 8" x 12" (203 x 203 x 305 mm) build envelope and ABSplus-P430 thermoplastic filament.

About Dimension Elite 3D Printer | Stratasys

Dimension 3D Printers

Stratasys Dimension Elite - Office 3D Printer

FDM Technology, About Fused Deposition Modeling | Stratasys

Eminence Speakers are designed and assembled in the USA | Eminence Speaker

About Dimension Elite 3D Printer | Stratasys

Dimension 3D Printers

Stratasys Dimension Elite - Office 3D Printer

FDM Technology, About Fused Deposition Modeling | Stratasys

Eminence Speakers are designed and assembled in the USA | Eminence Speaker

Attachments

I would have to disagree that compression drivers sound best in horns. Look at recent work by myself and Weltersys. A cone loaded horn has lower harmonic distortion than a compression driver in the mods mids for same SPL.

In some respects, we're making our own compression drivers.

AFAIK, if you have a conventional driver firing into a compression chamber, then you just made your own compression driver.

But this gets tricky when you consider "compression drivers" like the BMS 4540ND and the JBL D2. Those "compression drivers" actually don't have a compression chamber; the duct expands constantly, from the diaphragm all the way out to the mouth of the horn.

BTW, I know this is completely splitting hairs

In my experiments with using conventional tweeters on waveguides, I found that conventional tweeters frequently had lower distortion. I'm guessing that the reason for this is that compression drivers have very very little xmax, whereas conventional tweeters have a surround.

I am using dome tweeters in most of my waveguides nowadays.

Last edited:

Ive been drawing up ideas for a easy way to build a conical, or elliptical synergy/tractrix horn, and been looking at the idea of 3D printing the entry for the 1" driver and the tricky mounting of the 4 other drivers.

Shapeways now offers porcelain as an option, and the early ideas have these coming in at about £75.

Now I just need to learn SolidWorks as Sketchup is rubbish for this sort of thing...

I like 123D. I've heard good things about Fusion 360 too. Here's the set I'm currently working on for my Mazda, from the thread here : One Horn to Rule Them All - Car Audio | DiyMobileAudio.com | Car Stereo Forum

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.