Yesterday I did a lot of reading around on cabinet/baffle materials and construction. I've pretty much come to the conclusion that thick, void-free birch ply will be the best choice for me. I've never really liked anything made from MDF and all the things I thought about it have been commented on by others with much more experience... so I'll be avoiding it this time around. The stiffness and natural tone of ply will be a good starting point for best sound.

Sound aside, I won't have to finish it (bare MDF is ugly) and it's readily available. The only downside is it's a little harder to work with and many times the price for the best stuff.

I might pop in to my local timber merchant for some quotes.

I'm considering buying stuff with a veneer on, as that would look pretty... but then if I make any mistakes they'll stand out like a sore thumb!!!!

Simon

Sound aside, I won't have to finish it (bare MDF is ugly) and it's readily available. The only downside is it's a little harder to work with and many times the price for the best stuff.

I might pop in to my local timber merchant for some quotes.

I'm considering buying stuff with a veneer on, as that would look pretty... but then if I make any mistakes they'll stand out like a sore thumb!!!!

Simon

Hi Simon i can tell you that the felt I mentioned a while ago works well on a steel mid frame, don't forget the duct seal around the magnet - frame junction either, I still reckon you should try some of these cheap Jaycar woofers, HINT HINT You can always add mass to the ones you have.

Are the Skytronics paper?? If paper is it plain or treated?? i cannot remember so many threads so few brain cells remaining

Are the Skytronics paper?? If paper is it plain or treated?? i cannot remember so many threads so few brain cells remaining

Felt and duct seal, got it Ted  Just need to source those over here. Did you put that felt on the inside of the frame?

Just need to source those over here. Did you put that felt on the inside of the frame?

The Skytronics are plastic, unfortunately, not exactly ideal but they're what I could afford and I feel the lack of stiffness won't be a big issue in a dipole (due to the lack of cabinet pressurisation).

Simon

The Skytronics are plastic, unfortunately, not exactly ideal but they're what I could afford and I feel the lack of stiffness won't be a big issue in a dipole (due to the lack of cabinet pressurisation).

Simon

Well ; ( thinks out loud ) you can always use superglue and the felt buttons upholsterers use on mattresses. That would add at least 5 grams per button, perhaps some-one could work out for us what adding 30 grams of mass would do to T/S parameters

I used both the stiff felt pads, long thin and the soft felt in 2 layers on the inside spokes of the frame.

waste of time for woofers, worked on the mid-ranges

I used both the stiff felt pads, long thin and the soft felt in 2 layers on the inside spokes of the frame.

waste of time for woofers, worked on the mid-ranges

I could always trial added mass using coins and hot-melt glue... I think hot glue could be removed from a poly cone without ragging it to pieces. Perhaps I need to experiment on my current speakers!! These have lower Qts and Fs than the Skytronics so would be a good candidate for experimentation and education.

In the same way I could try cutting the dustcap off my little Audax mids (which sound slightly wrong to my ears) and doing EnABLe to them.

Someone e-mailed me today with some quite serious suggestions. I don't know if he wishes not to participate in the forum any longer but he is well known. He suggested a "butt cheek" horn for the tweeter, putting certain damping or deflecting panels behind the mid and running one of the 12inchers sealed with EQ and active XO. He also said side wings are bad and the baffle should be wider. This is a lot of work and doesn't fit in with what my room or abilities will take, but I want to understand the reasoning and use any of it that I can.

I could make the baffle a little wider (literally a few cms) and reduce and taper the wings to try and stay away from strong U-frame colourations. I do hear colour in my bass currently and am always thinking about how to reduce this droning (heard on certain music). An even bigger series coil might work.... better make an order!

Simon

In the same way I could try cutting the dustcap off my little Audax mids (which sound slightly wrong to my ears) and doing EnABLe to them.

Someone e-mailed me today with some quite serious suggestions. I don't know if he wishes not to participate in the forum any longer but he is well known. He suggested a "butt cheek" horn for the tweeter, putting certain damping or deflecting panels behind the mid and running one of the 12inchers sealed with EQ and active XO. He also said side wings are bad and the baffle should be wider. This is a lot of work and doesn't fit in with what my room or abilities will take, but I want to understand the reasoning and use any of it that I can.

I could make the baffle a little wider (literally a few cms) and reduce and taper the wings to try and stay away from strong U-frame colourations. I do hear colour in my bass currently and am always thinking about how to reduce this droning (heard on certain music). An even bigger series coil might work.... better make an order!

Simon

Hi Simon,

building your own loudspeakers is all about compromises and preferences. What will work in one aspect may make things worse for another aspect. And the sound that appeals to one man may make the next one run away.

So there is no need to obey anyone - its worse: For any one question you will get two divergent answers (at least). And you have to decide which one to choose. How about throwing dice?

Slanting the side wings is such a compromise. It could reduce a resonance, if you hear one. And it will reduce the bass level, but may be you don´t need that much. I believe this is a classic cardbord area: Try with cheap material what happens and decide for yourself.

I never experienced "strong U frame colourations" from my own dipole bass constructions, but I always made sure to avoid real resonance peaks (what your U frame does too) and crossed over low enough.

WRT a wider baffle I have just posted my thoughts at the Audiocircle OB forum. It would not make sense to repeat myself in this thread. And it concentrates on midrange and treble issues, which you already have nicely covered. I just mention it because the issue came up.

BTW: I never use MDF, because I simply don´t like the look and feel. Ply is what I prefer too. My local dealer has "silk screen ply". Don´t ask why it is called like that, but it is a much cheaper ply version that doesn´t care as much for looks as regular baltic birch ply.

Rudolf

building your own loudspeakers is all about compromises and preferences. What will work in one aspect may make things worse for another aspect. And the sound that appeals to one man may make the next one run away.

So there is no need to obey anyone - its worse: For any one question you will get two divergent answers (at least). And you have to decide which one to choose. How about throwing dice?

Slanting the side wings is such a compromise. It could reduce a resonance, if you hear one. And it will reduce the bass level, but may be you don´t need that much. I believe this is a classic cardbord area: Try with cheap material what happens and decide for yourself.

I never experienced "strong U frame colourations" from my own dipole bass constructions, but I always made sure to avoid real resonance peaks (what your U frame does too) and crossed over low enough.

WRT a wider baffle I have just posted my thoughts at the Audiocircle OB forum. It would not make sense to repeat myself in this thread. And it concentrates on midrange and treble issues, which you already have nicely covered. I just mention it because the issue came up.

BTW: I never use MDF, because I simply don´t like the look and feel. Ply is what I prefer too. My local dealer has "silk screen ply". Don´t ask why it is called like that, but it is a much cheaper ply version that doesn´t care as much for looks as regular baltic birch ply.

Rudolf

Hi Rudolf,

Great thread you have going there, very informative, and nice to see a link to Jamo R909 measurements - an impressive speaker.

FWIW I suspect Jamo made the baffle wide all the way up for looks and maybe simplicity of construction, more than sound.

I'm not sure how easy it will be to test wings vs no wings - maybe I'll need a very simple test baffle, not necessarily made the from final material - and add boards - maybe just card - to that.

Some open baffle design approaches certainly do contradict one another, so I need to think about what I can personally achieve, what I like and what I've actually heard / experienced myself.

I've just made the order for various coils and caps from my good friend Lee at www.diyhi-fi.co.uk. Progress is still steady..

Simon

Great thread you have going there, very informative, and nice to see a link to Jamo R909 measurements - an impressive speaker.

FWIW I suspect Jamo made the baffle wide all the way up for looks and maybe simplicity of construction, more than sound.

I'm not sure how easy it will be to test wings vs no wings - maybe I'll need a very simple test baffle, not necessarily made the from final material - and add boards - maybe just card - to that.

Some open baffle design approaches certainly do contradict one another, so I need to think about what I can personally achieve, what I like and what I've actually heard / experienced myself.

I've just made the order for various coils and caps from my good friend Lee at www.diyhi-fi.co.uk. Progress is still steady..

Simon

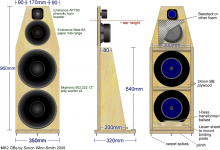

Because of advice from guys here and Thorsten Loesch via e-mail I've decided to taper the wings quite a bit to hopefully reduce their audible degradations.

To (very slightly) make up for the reduced side wings I've made the baffles as wide as possible for my room - 35cm.

Also as per Thorsten's recommendations I will add some Basotect or foam with similar acoustic properties behind the mid driver to reduce excessive rear output. Being close to the rear wall necessitates this, I'm told.

I will be researching materials to experiment with behind the woofers to increase their effective Qts, as suggested by Graham Maynard. I'll try this on my current speakers (Qts = 0.40) first. I found through experimentation that increasing effective Q by inserting series resistance (in the low-pass coil) actually REDUCES apparent deep bass output, by some mechanism I don't well understand. With a lower DCR coil there is deeper, tighter, punchier bass.

I've now decided on 24mm baltic birch ply or maybe 24mm spruce ply to construct these from, which my newest diagram factors in.

Check it out, attached.

To (very slightly) make up for the reduced side wings I've made the baffles as wide as possible for my room - 35cm.

Also as per Thorsten's recommendations I will add some Basotect or foam with similar acoustic properties behind the mid driver to reduce excessive rear output. Being close to the rear wall necessitates this, I'm told.

I will be researching materials to experiment with behind the woofers to increase their effective Qts, as suggested by Graham Maynard. I'll try this on my current speakers (Qts = 0.40) first. I found through experimentation that increasing effective Q by inserting series resistance (in the low-pass coil) actually REDUCES apparent deep bass output, by some mechanism I don't well understand. With a lower DCR coil there is deeper, tighter, punchier bass.

I've now decided on 24mm baltic birch ply or maybe 24mm spruce ply to construct these from, which my newest diagram factors in.

Check it out, attached.

Attachments

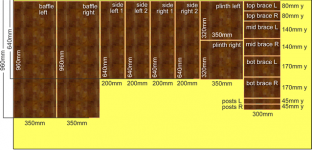

In case anyone's wondering how neatly that can be cut from a 2.4 x 1.2m sheet of plywood, here it is (accurate scale). It's something like £70+vat for a sheet from Arnold Laver!! I think it will be worth it though.

Oh and my Monacor spikes arrived yesterday, cheap and cheerful, they work and are adjustable so I can put in a slight tilt if I want.

Oh and my Monacor spikes arrived yesterday, cheap and cheerful, they work and are adjustable so I can put in a slight tilt if I want.

Attachments

Gosh, it's been three weeks, but I've not been standing still!

In the last few days I've received or gone and bought:

* M5 t-nuts and lovely black allen bolts

* initial crossover experimental parts

* the 24mm plywood, cut

* PVA glue

* Kimber Kwik-16 speaker cable (for woofer connections)

I'm arranging or awaiting delivery of:

* duct seal (to mould on the Beta 8 frames)

* EnABL kit from EdLafontaine to treat Beta8 cone

* single binding posts for Beta 8A frames - to earth them

Already lying around:

* quality CMC binding posts

* Eminence Beta PA midwoofer 8A x2

* Eminence APT-80 (C/W small screw-on horn)

* 500VA Airlink toroids for T-bass implementation

Simon

In the last few days I've received or gone and bought:

* M5 t-nuts and lovely black allen bolts

* initial crossover experimental parts

* the 24mm plywood, cut

* PVA glue

* Kimber Kwik-16 speaker cable (for woofer connections)

I'm arranging or awaiting delivery of:

* duct seal (to mould on the Beta 8 frames)

* EnABL kit from EdLafontaine to treat Beta8 cone

* single binding posts for Beta 8A frames - to earth them

Already lying around:

* quality CMC binding posts

* Eminence Beta PA midwoofer 8A x2

* Eminence APT-80 (C/W small screw-on horn)

* 500VA Airlink toroids for T-bass implementation

Simon

Attachments

I bought the 24mm Baltic Birch (Latvian) plywood from Arnold Laver. They couldn't really tell me much about it and were stunned themselves at how much it costs but it's simply stunning! I paid £80 including cutting, which I think is reasonable. There was a lot of cutting to do, and those guys did a terrific job.

Although not specifically sold as void-free, it doesn't have any real gaps at the edges, and the knots have been machined out and plugged with wood.

Here's a pic of all the main parts for one speaker.

Although not specifically sold as void-free, it doesn't have any real gaps at the edges, and the knots have been machined out and plugged with wood.

Here's a pic of all the main parts for one speaker.

Attachments

It has something like 17 plys and the finish on top is wonderful, I won't be putting anything on it at all - this is a bonus with this design as there's not much woodworking (other than what any timber merchants will do for you) and no painting or varnishing (I find varnish ugly).

Here's one speaker standing aided by nothing more than gravity.

Here's one speaker standing aided by nothing more than gravity.

Attachments

Here's a printout from the Excel spreadsheet someone provided on the "Geddes on Waveguides" thread elsewhere on here (will find link and credit later).

As per the instructions, I set the parameters in the spreadsheet to give it a 1" throat size and just under 8" overall diameter. It looks like it's only going to need three sheets of plywood to achieve the correct depth.

I want to use a waveguide to better match the dispersion characteristics of the midrange unit and lower distortion. Most importantly, Thorsten said I need one!

As per the instructions, I set the parameters in the spreadsheet to give it a 1" throat size and just under 8" overall diameter. It looks like it's only going to need three sheets of plywood to achieve the correct depth.

I want to use a waveguide to better match the dispersion characteristics of the midrange unit and lower distortion. Most importantly, Thorsten said I need one!

Attachments

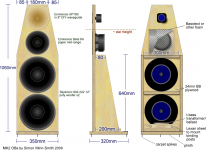

Here's a very rough mock-up of how it will look with the waveguides in place. Out of necessity it's quite a tall speaker now.

Depending on where the acoustic centre of each driver is determined to be in relation to the listening / ear height, the waveguide may protrude from the baffle slightly. This being the case, it could potentially overlap the mid driver a little - if this is deemed to be wise.

Your thoughts gentlemen.

Simon

Depending on where the acoustic centre of each driver is determined to be in relation to the listening / ear height, the waveguide may protrude from the baffle slightly. This being the case, it could potentially overlap the mid driver a little - if this is deemed to be wise.

Your thoughts gentlemen.

Simon

Attachments

Simon, thanks for posting this. I am about to start a much simpler OB based on the Alpha 15 and fostex FE103E, and I can learn from your experiences. Tell me, where did you source the inductors and caps? everywhere I look they are silly money! I too plan on using BBply, maybe with a veneer, not cheap as you say.

Looks like you are in for some serious smiling when they are finished!

Steve

Looks like you are in for some serious smiling when they are finished!

Steve

Hi Steve,

Thanks for your encouraging comments. I think you too will be smiling when you hear your Alpha 15. I'm not sure about Fostex drivers but done like this I think you must be onto a winner!

I get my caps and coils from my good friend Lee @ http://www.diyhi-fi.co.uk/

I'll ask him to show his face here, you'll need to contact him directly to get access to the full range of coils and caps - he can order anything from Mundorf (but they are a bit slow - WELL worth the wait of course). And bear in mind if you order elsewhere in the UK (I've tried at a couple of places) you'll also wait a long time because nobody (AFAIK) keeps stock of a wide range of Mundorf or other quality coils and large bipolar caps.

Simon

Thanks for your encouraging comments. I think you too will be smiling when you hear your Alpha 15. I'm not sure about Fostex drivers but done like this I think you must be onto a winner!

I get my caps and coils from my good friend Lee @ http://www.diyhi-fi.co.uk/

I'll ask him to show his face here, you'll need to contact him directly to get access to the full range of coils and caps - he can order anything from Mundorf (but they are a bit slow - WELL worth the wait of course). And bear in mind if you order elsewhere in the UK (I've tried at a couple of places) you'll also wait a long time because nobody (AFAIK) keeps stock of a wide range of Mundorf or other quality coils and large bipolar caps.

Simon

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- 3 way open baffle with Eminence and Skytronic