Dear Arul,

nice to see a single sided pcb variant of the initial input stage of the SA2014 release (old name was SA2013). A better, safer and extremely stable version can be found reading the index (first post) and use the schematics from the links provided in step

nice to see a single sided pcb variant of the initial input stage of the SA2014 release (old name was SA2013). A better, safer and extremely stable version can be found reading the index (first post) and use the schematics from the links provided in step

A) SA2014 (200W@8R, 400W@4R)

BR, Toni

Dear Arul,

nice to see a single sided pcb variant of the initial input stage of the SA2014 release (old name was SA2013). A better, safer and extremely stable version can be found reading the index (first post) and use the schematics from the links provided in stepA) SA2014 (200W@8R, 400W@4R)BR, Toni

Ok.Thank's sir.

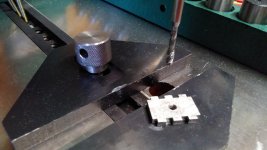

case preparation - tools

... after several years of searching I found a simple hand tapping machine which saves me a lot of time (19 kg; up to 190mm wide so I can prepare metal plates which are up to 380mm wide).

BR, Toni

... after several years of searching I found a simple hand tapping machine which saves me a lot of time (19 kg; up to 190mm wide so I can prepare metal plates which are up to 380mm wide).

BR, Toni

Attachments

... after several years of searching I found a simple hand tapping machine

Link?

I've tried just about every tapping machine available over the years and still prefer a good quality cordless drill. If absolute precision is needed I use a tapping head in a milling machine but a cordless drill is tall enough to give you an excellent perspective of squareness.

Google "hand tapping machine"

You said it took you "several years"! Couldn't you just give us a link instead of teasing

I've tried just about every tapping machine available over the years and still prefer a good quality cordless drill....

The small part I showed above is stainless steel 3mm thick. I have done a few with my li-on power drill but never got it exactly 90 degree...

Using a cordless drill oder li-on power drill for M3 is a nightmare because you can easy destroy your M3 tapping drill and therefore convert your expensive heatsink to cheap metal waste.

Last edited:

You said it took you "several years"! Couldn't you just give us a link instead of teasing

Sorry! I've never seen such a machine before but often searched for a simple tool. Sometimes you don't know the correct words to search for ...

I've bought it here:

https://www.zujeddeloh.de/produkte/...chneiden_--366/gewindebohrapparat--_5621.html

and found it here too:

https://www.amazon.com/Grizzly-G874...ref=sr_1_2?s=hi&keywords=Hand+Tapping+Machine

BR, Toni

... after several years of searching I found a simple hand tapping machine which saves me a lot of time (19 kg; up to 190mm wide so I can prepare metal plates which are up to 380mm wide).

BR, Toni

How well does that work with small threads, such as M3?

I currently use a T bar tapper as shown in the attached picture. That works fine although you need to be careful to tap straight into the hole.

Attachments

Sorry! I've never seen such a machine before but often searched for a simple tool. Sometimes you don't know the correct words to search for ...

I've bought it here:

https://www.zujeddeloh.de/produkte/...chneiden_--366/gewindebohrapparat--_5621.html

and found it here too:

https://www.amazon.com/Grizzly-G874...ref=sr_1_2?s=hi&keywords=Hand+Tapping+Machine

BR, Toni

Thanks!

How well does that work with small threads, such as M3?

...

I have the same tool and after tapping about 25 x M3 for my quad channel SA2014 I started to be tired and broke the M3 tapping drill ... heatsink useless ...

The small part I showed above is stainless steel 3mm thick. I have done a few with my li-on power drill but never got it exactly 90 degree...

Using a cordless drill oder li-on power drill for M3 is a nightmare because you can easy destroy your M3 tapping drill and therefore convert your expensive heatsink to cheap metal waste.

I do M3 in heatsinks all the time with no issues. There are a couple key things needed to be successful though. The heatsink needs to be real aluminum (T6063-t6) not the Ebay crap with all the garbage in it and it needs to be drilled with a sharp drill bit with coolant so the aluminum doesn't get hot and anneal.

The problem is not the heat. I too use a special drill lubricant.

The problem is the exact 90 degree angle and trembling fingers of an "old" man ... crack ... drill bit is gone ... heatsink too...

BTW: I do not use cheap heatsinks. They are made by cooltec and length cutted by them exactly for my needs! Best you can get!

The problem is the exact 90 degree angle and trembling fingers of an "old" man ... crack ... drill bit is gone ... heatsink too...

BTW: I do not use cheap heatsinks. They are made by cooltec and length cutted by them exactly for my needs! Best you can get!

I use a base drill and then,after drilling,a hand tool for tapping.The problem is not the heat. I too use a special drill lubricant.

The problem is the exact 90 degree angle and trembling fingers of an "old" man ... crack ... drill bit is gone ... heatsink too...

BTW: I do not use cheap heatsinks. They are made by cooltec and length cutted by them exactly for my needs! Best you can get!

Yes isn't an easy way for 90 degree angle perfect tapping.

I guess this depends on how often you tap holes. This is a daily thing for me for 25+ years. I can tap perfectly straight (or straighter than the threads on the fastener) with a Milwaukee cordless drill. It I try to use one of those crappy T-handle tap wrenches I get it crooked just about every time. The extra length of the drill allows me to judge the angle a lot easier.

This is the "poor man's"  version for hand tapping 90 degree ...

version for hand tapping 90 degree ...

https://www.zujeddeloh.de/produkte/werkzeuge_+_zubehoer/gewindeschneiden_--366/gewindebohrvorrichtung--_6351.html

https://www.zujeddeloh.de/produkte/werkzeuge_+_zubehoer/gewindeschneiden_--366/gewindebohrvorrichtung--_6351.html

Yes Jeff, your guess is right!I guess this depends on how often you tap holes. This is a daily thing for me for 25+ years. I can tap perfectly straight (or straighter than the threads on the fastener) with a Milwaukee cordless drill. It I try to use one of those crappy T-handle tap wrenches I get it crooked just about every time. The extra length of the drill allows me to judge the angle a lot easier.

My first attempt for tapping was some years ago.

... frontpanel is inserted ... easy removeable ... all parts fit so far ... puuuh

A very-very well done diy enclosure!

- Home

- Amplifiers

- Solid State

- 2stageEF high performance class AB power amp / 200W8R / 400W4R