I've used Wakefield 637-20ABP on multiple designs, including 300B heating with very good, cool results. These can handle 5W dissipation under chassis with some breathing holes above for airflow. PCB mounting is very convenient and compact. Cheap, too.

They also make a 63mm high version, but it's not typically in stock. I also use a skinnier version for TO-220 rectifier and power resistor mounting.

My preference is to stay off the direct-to-chassis mounting of semi's, but to each his own.

Thanks Kurt, that's useful.

The Wakefield Heatsink version is available from Mouser.

Also available in Europe, the Avid Thermally SW50 (8.8K/W) and SW63(6K/W) appear to be mechanically compatible, with a PCB footprint of 12.5mm x 34.5mm, with 2.5mm (.098") pins on 25.4mm (1") centres.

The drawing for the 63mm high version is here:

Standard Board Level Heat Sinks

This design has good power handling, easy PCB integration, low price, wide availability - I better adopt it for the board design!

Does the 50mm or 63mm height give anyone a problem?

I use 2U rack parts for my chassis, so my chassis height is 88mm. I think visually speaking the best solution for serious heatsinks is the time honoured practice of bolting them on the back plate. They're out of the way and this looks satisfying to me - you can use a fancy front, wood sides etc. I tend to put the connectors and knobs on the top plate since they're easier to plug in and out and you get the whole circuit on one plate.

So for me, it would be something like this, with 75mm height. It comes in various widths.

FISCHER ELEKTRONIK|SK 47/75 SA|HEAT SINK, 75MM, 0.45 - 1.05°C | Farnell United Kingdom

Andy

So for me, it would be something like this, with 75mm height. It comes in various widths.

FISCHER ELEKTRONIK|SK 47/75 SA|HEAT SINK, 75MM, 0.45 - 1.05°C | Farnell United Kingdom

Andy

Hi Andy,

very good idea!

I will try to use the Caddock MP9100 10 Ohm:

http://www.caddock.com/Online_catalog/Mrktg_Lit/AEN0102.pdf

And a bigger <1 K/W heatsink

KR Hauke

very good idea!

I will try to use the Caddock MP9100 10 Ohm:

http://www.caddock.com/Online_catalog/Mrktg_Lit/AEN0102.pdf

And a bigger <1 K/W heatsink

KR Hauke

http://uk.farnell.com/fischer-elektronik/sk-42-75-sa/heat-sink-75mm-1-2-c-w/dp/4621955?Ntt=4621955

Cheaper version. Actually my 75mm "height" which is the height of the back plate, is listed as Depth. Height is how far it projects back from the rear wall when mounted vertically on it, as it should be.

Andy

Cheaper version. Actually my 75mm "height" which is the height of the back plate, is listed as Depth. Height is how far it projects back from the rear wall when mounted vertically on it, as it should be.

Andy

Last edited:

Just an update on the 10y in filament bias. I got some chokes - 280mH at 2.7A. I'm currently listening to a Thurlby bench supply going through these smoothing chokes into the 10Y.

Sound is exceptionally clear - in complex passages you can hear the discrete sounds of instruments more clearly. That's the predominant effect.

The chokes are moderately big beasts. Will have to work out where to put everything on the chassis for a more definitive build.

I know this is a 26 thread, but all this design would work for the 26 if you substituted a LL1660/5mA for the Hammond 126c I'm using. Hammond do suitable filament chokes as well.

I'm really enjoying all this!

Andy

Sound is exceptionally clear - in complex passages you can hear the discrete sounds of instruments more clearly. That's the predominant effect.

The chokes are moderately big beasts. Will have to work out where to put everything on the chassis for a more definitive build.

I know this is a 26 thread, but all this design would work for the 26 if you substituted a LL1660/5mA for the Hammond 126c I'm using. Hammond do suitable filament chokes as well.

I'm really enjoying all this!

Andy

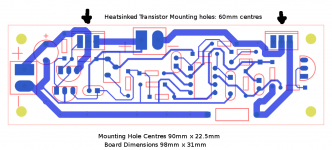

Tried to lay out the design with the PCB-mounted heatsinks AND keep it compatible with bigger chassis mounted types. This did not work out, and since some bigger filaments need bigger sinks, I've stuck to those, and left out the PCB versions.

The Board is ready to go out...

Here's the dimensions and hole positions - how do these work out on your chassis??

The Board is ready to go out...

Here's the dimensions and hole positions - how do these work out on your chassis??

Attachments

Member

Joined 2006

Hi,

i could not get rid of my hum, probably produced by my heater supply.

2*16V AC heater trannies, followed by MUR820 diodes and 15000uF then a reg circuit with L200, 15mH choke and then a LT1084 board:

And here is a photo of my 26 signal board:

What should i do?

KR Barossi

i could not get rid of my hum, probably produced by my heater supply.

2*16V AC heater trannies, followed by MUR820 diodes and 15000uF then a reg circuit with L200, 15mH choke and then a LT1084 board:

An externally hosted image should be here but it was not working when we last tested it.

And here is a photo of my 26 signal board:

An externally hosted image should be here but it was not working when we last tested it.

What should i do?

KR Barossi

If the hum is from your filament supply, you could try adding a common mode choke.

I made a Ronan Reg based filament supply (2 voltage regs followed by a current reg) for a 1LE3 linestage and the amount of cr** that got through was incredible. A change of filament transformer and addition of a CMC made quite a remarkable difference.

However, all that exposed unshielded wiring has got me wondering whether the primary cause may lie elsewhere.

I made a Ronan Reg based filament supply (2 voltage regs followed by a current reg) for a 1LE3 linestage and the amount of cr** that got through was incredible. A change of filament transformer and addition of a CMC made quite a remarkable difference.

However, all that exposed unshielded wiring has got me wondering whether the primary cause may lie elsewhere.

The transformers are susceptible to local ac magnetic fields, and the 26 is extremely susceptible to electro-static pick up. (Anything closer than 1 meter may interfere) Putting everything in a metal chassis or even just use some copper or AL foil to shield around (under) the circuitry may help. The foil must be grounded to your audio ground to be effective.

Member

Joined 2006

Member

Joined 2006

Hi,

i could not get rid of my hum, probably produced by my heater supply.

2*16V AC heater trannies, followed by MUR820 diodes and 15000uF then a reg circuit with L200, 15mH choke and then a LT1084 board:

An externally hosted image should be here but it was not working when we last tested it.

And here is a photo of my 26 signal board:

An externally hosted image should be here but it was not working when we last tested it.

What should i do?

KR Barossi

Most of the hum issues got resolved in my 26 pre after correctly configuring the grounding. It is worth to check.

Anyone could an idea how to improve bass response with the 26 pre? (or rather explain ways to fine tune bass.)

Possibly assuming that other system issues are not responsible it may be time for a really good quality plate to line transformer..No one who has built one of the several versions of my transformer coupled line stage has ever complained about bass response. The low source impedance so provided will allow you to drive any power amplifier well - at the expense of gain of course.

Otherwise you should post your current design and let us have a look.. And tell us what is being used with it in as much detail as is reasonably possible..

An RC or CCS loaded 26 will have a source impedance of about 8K which is not particularly good for driving a solid state amp, nor any amp with an input impedance of less than 75K.. The size of the coupling capacitor plays a role as does any HPF that may be present at the input of your amp, which IIRC is solid state..

Other factors may play a role here, do you have another pre-amp that performs better in this regard? Speaker design, placement, listening position, and many other things may contribute here. What are your speakers - and do they need/use BSC (baffle step compensation)?

Possibly assuming that other system issues are not responsible it may be time for a really good quality plate to line transformer..No one who has built one of the several versions of my transformer coupled line stage has ever complained about bass response. The low source impedance so provided will allow you to drive any power amplifier well - at the expense of gain of course.

Otherwise you should post your current design and let us have a look.. And tell us what is being used with it in as much detail as is reasonably possible..

An RC or CCS loaded 26 will have a source impedance of about 8K which is not particularly good for driving a solid state amp, nor any amp with an input impedance of less than 75K.. The size of the coupling capacitor plays a role as does any HPF that may be present at the input of your amp, which IIRC is solid state..

Other factors may play a role here, do you have another pre-amp that performs better in this regard? Speaker design, placement, listening position, and many other things may contribute here. What are your speakers - and do they need/use BSC (baffle step compensation)?

Perhaps parafeed output (CCS + step down ungapped transformer), .. at the expense of some gain ...

- Home

- Amplifiers

- Tubes / Valves

- #26 pre amp