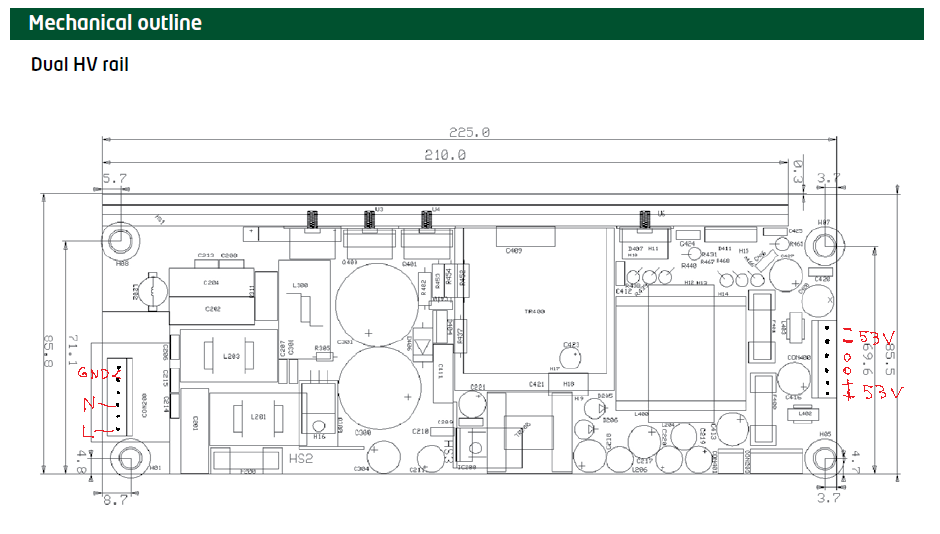

should be a bit better than "unabletec"could someone take a picture of that supply and show the plus and minus rail terminals? the pdf left me confused

They are quite a reputable Norwegian company, and the product seems solid.

The diagram is vague because the headers don't show where pin 1 is, but with a voltmeter/continuity meter I was able to determine which pins are which. But please double check with a continuity meter yourself to see where earth gnd is on AC line input. The after plugging in line input, use a voltmeter to find where + and - 53v and 5.5v and 7.5v are. This is not a project for a newbie with power supplies, you could get zapped.

Here is the pin diagram I used:

Attachments

the company that designed it Anaview/Abeltech is/was reputable but it appears to be built incorrectly by an Asian contractor. I bought several of them a year or so ago from PE and none came anywhere close to their medium and short term power specs and only some of them came close to the long term spec. I emailed both ABELTECH and Patrick asking for information that would allow them to be made to operate as designed and got no reply. PE provided replacements which performed in the same sub par way and then allowed return and refund. They hadn't tested them and apparently had purchased them from someone who realized that they did not perform as specified and dumped them. They will work at 100w level per output and be ok on typical music duty cycles except for subwoofer with sustained signals. A good value if used within their limitations

How do you like the LJM IRS2092?

Actually, I had only 1 IRS2092 (from LJM) so I can't compare to others

I can compare it with my TPA3116

my LJM 2092 is modded as it was described in this forum.

my TPA 3116 is the YJ blue board fully modded

as far I remember (it was 2 years ago), LJM 2092 sounds more HIFI than TPA3116, mainly in the highs.

But I don't know why, it is very hard to listen more than 1 hour with IRS 2092. very frustrating.

I still have my 2092, maybe I need another test, and upgrade with OSCAN caps.

interesting Capt. Grogg - would you think using only one IRS2092 module for bass guitar or drum machine to work reliably ? - - X - are the terminals marked "o" between the plus and minus pins not connected or are they the centertap? must there be some load to safely check the output pins?

Last edited:

that's what I was thinking, why they are so cheap E.g. US buyer bailed out after failed testing and or other things like no agency approvals on record.

how do they implement overload protection was my 1st concern (>800W can be easily into fire territory). shock hazards are DIY normal hazard but can be done better than shown.

how do they implement overload protection was my 1st concern (>800W can be easily into fire territory). shock hazards are DIY normal hazard but can be done better than shown.

Last edited:

interesting Capt. Grogg - would you think using only one IRS2092 module for bass guitar or drum machine to work reliably ? - - X - are the terminals marked "o" between the plus and minus pins not connected or are they the centertap? must there be some load to safely check the output pins?

0=center tap

the company that designed it Anaview/Abeltech is/was reputable but it appears to be built incorrectly by an Asian contractor. I bought several of them a year or so ago from PE and none came anywhere close to their medium and short term power specs and only some of them came close to the long term spec. I emailed both ABELTECH and Patrick asking for information that would allow them to be made to operate as designed and got no reply. PE provided replacements which performed in the same sub par way and then allowed return and refund. They hadn't tested them and apparently had purchased them from someone who realized that they did not perform as specified and dumped them. They will work at 100w level per output and be ok on typical music duty cycles except for subwoofer with sustained signals. A good value if used within their limitations

What were the values you tested at? Are you saying they are only capable of 100w continuous not 450watts? That is quite the difference. The sheet says sustained testing requires heatsink to be heat sinked externally. Did you do that ? What is troubling is that they claim they passed rigorous testing body standard for 5min duration to meet the higher 900 w rating.

a real image of the bottom sides would be good

invest in some decent hook up wires for twisted pairs , speaker wires are usually dubious sourced things ( the AWG size isn't reliable AND they probly aren't all real copper, Al plated strands in the wire is more and more common now ) They are pinching all the copper away for your savings. I reckon most ppl don't notice the nitty gritty details looking at price 1st. this wire problem is even worse in car audio and jumper cables.

invest in some decent hook up wires for twisted pairs , speaker wires are usually dubious sourced things ( the AWG size isn't reliable AND they probly aren't all real copper, Al plated strands in the wire is more and more common now ) They are pinching all the copper away for your savings. I reckon most ppl don't notice the nitty gritty details looking at price 1st. this wire problem is even worse in car audio and jumper cables.

Last edited:

Normally in Europe safety instructions come with open frame SMPS. Most likely here they would say to keep a clearance of 5 or 6mm, don't run cables over the SMPS, and maybe what kind of insulation sheets to use. Also most likely tell you to only use supplied or optional cabling designed for that SMPS I don't know if like 100strand 18ga cable if used is ok here, pvc insulation I feel isn't ok and dropping all cables you have on top of openframe SMPS isn't ok.

I don't know if like 100strand 18ga cable if used is ok here, pvc insulation I feel isn't ok and dropping all cables you have on top of openframe SMPS isn't ok.

indeed this isn't even a open frame its a "frame not included" clearly earth grounding needs to be looked at too. is the heat sink wired to ground? is the secondary common grounded? I would place warning signs and keep small children and pets away for sure.Normally in Europe safety instructions come with open frame SMPS. Most likely here they would say to keep a clearance of 5 or 6mm, don't run cables over the SMPS, and maybe what kind of insulation sheets to use. Also most likely tell you to only use supplied or optional cabling designed for that SMPSI don't know if like 100strand 18ga cable if used is ok here, pvc insulation I feel isn't ok and dropping all cables you have on top of openframe SMPS isn't ok.

Last edited:

BTW normal salesprice including VAT here in Europe for this Abletec SMPS is $299 ex shipping ALP0400-NB54

Yes, heatsink is connected to earth ground. This is in my speaker lab so no kids or pets and I unplug when not attended. I realize it's a high risk for anything but specialized testing. I'm surprised no one said anything about it being mounted to an xps foam insulation board.

BTW normal salesprice including VAT here in Europe for this Abletec SMPS is $299 ex shipping ALP0400-NB54

$19 here in US is a deal then

I think it was designed for mounting inside a metal frame or plate, you can tell by looking at the PCB wiring to the standoffs. (the documentation provided no guides?) I only wondered why you bothered to use wood under the amps but not the supply. otherwise your building / wiring materials and choices seem to be highly constrained. your insurance company investigator may ask why later onYes, heatsink is connected to earth ground. This is in my speaker lab so no kids or pets and I unplug when not attended. I realize it's a high risk for anything but specialized testing. I'm surprised no one said anything about it being mounted to an xps foam insulation board.

Last edited:

- Home

- Amplifiers

- Class D

- 200W IRS2092 Amp for $20