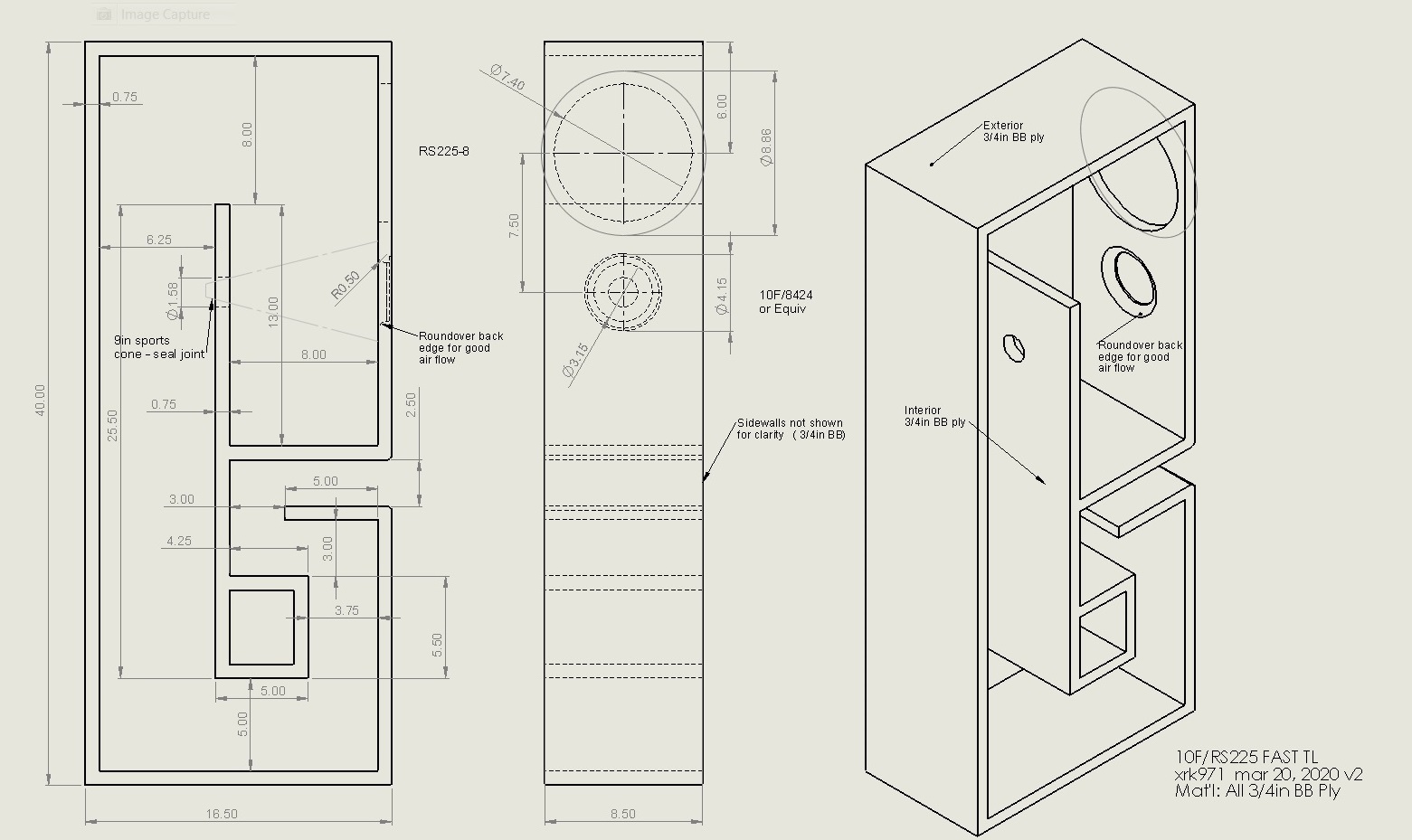

Here is the all 3/4in BB plywood plans.

That's a pretty easy build, from a quick look over. I might have to give this one a try later this spring. Neck deep in house re-model at the moment.

As 1/2" (12mm) BB is easily available to me, but 18mm is at least an hour drive each way, I might try to build them in ~25.4mm. I would keep the TL internal dimensions the same, of course, and likely chamfer the vertical sides and top edge.

Since the internal span isn't that great, do you think making the top/bottom/baffle/rear and sides from ~25mm, and the internal TL panels from ~12mm would work? I could always line the internal TL panels with some noico cld material or similar.

Hi Pcgab,

Your plan to double up the exterior pieces to 1in and leave internal 1/2in is fine. Make sure your route round overs for driver cutouts to breathe easy. The double panel opens up CLD possibilities too maybe use a softer adhesive like latex based sub floor glue. Lining with Noico auto sound damping is a good idea too. Especially large spans that can be drum like. The 2 layer CLD panels probably won’t need Noico.

Your plan to double up the exterior pieces to 1in and leave internal 1/2in is fine. Make sure your route round overs for driver cutouts to breathe easy. The double panel opens up CLD possibilities too maybe use a softer adhesive like latex based sub floor glue. Lining with Noico auto sound damping is a good idea too. Especially large spans that can be drum like. The 2 layer CLD panels probably won’t need Noico.

Hi Pcgab,

Your plan to double up the exterior pieces to 1in and leave internal 1/2in is fine. Make sure your route round overs for driver cutouts to breathe easy. The double panel opens up CLD possibilities too maybe use a softer adhesive like latex based sub floor glue. Lining with Noico auto sound damping is a good idea too. Especially large spans that can be drum like. The 2 layer CLD panels probably won’t need Noico.

That's what I was thinking. Thank you X!

Did some digging.

The 10f is impressive, expensive, but that last 10% can cost 400% more sometimes !!!!

I’ve had fiberglass weave cones (slightly scratchy sounding but otherwise good), but these are also coated and a squeak of Kevlar with the paper pulp for stiffening ?

I do like morel cones, poly stiffened with talc powder.

Think I’m getting some 10f for my birthday in a few weeks.

The 10f is impressive, expensive, but that last 10% can cost 400% more sometimes !!!!

I’ve had fiberglass weave cones (slightly scratchy sounding but otherwise good), but these are also coated and a squeak of Kevlar with the paper pulp for stiffening ?

I do like morel cones, poly stiffened with talc powder.

Think I’m getting some 10f for my birthday in a few weeks.

Last edited:

Try TC9FD then. Just reduce the padding on the tweeter resistors as it’s 2dB less than 10F. Only $10 and sounds quite good. Has a non round bezel though which is a pain.

Other ones to try: 3FE22 or 3FE25, RS100-8, FR58EX, PS95-8, FF85WK. They will all work with some resistor adjustments. Just choose your flavor. The PS95-8 is particularly “exciting” and “fun” sounding. 3FE22 is detailed and smooth. RS100 has good balance and nice highs.

Other ones to try: 3FE22 or 3FE25, RS100-8, FR58EX, PS95-8, FF85WK. They will all work with some resistor adjustments. Just choose your flavor. The PS95-8 is particularly “exciting” and “fun” sounding. 3FE22 is detailed and smooth. RS100 has good balance and nice highs.

Try TC9FD then. Just reduce the padding on the tweeter resistors as it’s 2dB less than 10F. Only $10 and sounds quite good. Has a non round bezel though which is a pain.

Other ones to try: 3FE22 or 3FE25, RS100-8, FR58EX, PS95-8, FF85WK. They will all work with some resistor adjustments. Just choose your flavor. The PS95-8 is particularly “exciting” and “fun” sounding. 3FE22 is detailed and smooth. RS100 has good balance and nice highs.

I can vouch for the FF85WK, they sound fantastic in this configuration.

I'm hoping to try TC9 soon as well, I have a few on hand so why not.

I would like to try 4FE35's since I have some, but I'm not sure they'll work....

Yes, FF85WK is a nice sounding driver. It can’t take much power though.

Very true.

On the other hand that driver would be be high passed so much of the power would be diverted to the woofer. Also you would not need much excursion either, so the only consideration would be heating the voice coil through sustained loud music. Classical music typically does not have high long term power requirements, only peaks due to crescendoes.

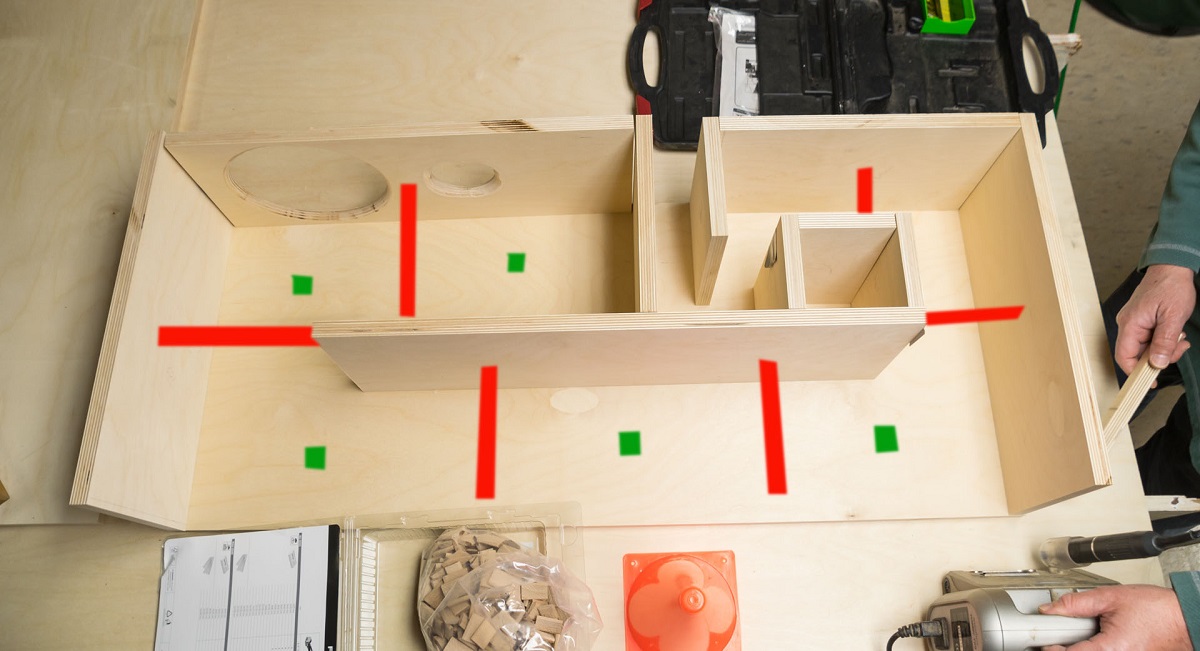

Some progress on the BB ply 10F/RS225 FAST TL build by a couple of collaborators working with me in Northern Virginia.

Cutting holes for the driver and adding round overs on the backside for good air flow:

Bracing plan:

Dryfit test:

We are about ready for gluing up the first one today.

Cutting holes for the driver and adding round overs on the backside for good air flow:

Bracing plan:

Dryfit test:

We are about ready for gluing up the first one today.

Attachments

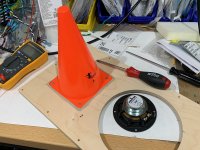

After getting some motivation from Zman01 on his impending B80/RS225 build, I decided to get cracking on mine. I have had these baffles cutout for almost 2 years now. Finally got around to gluing the sports cone to the baffle for the Dagger rear chamber. I used Loctite PL500 adhesive and 4 wood screws. I will test it out with the stock crossover with maybe less padding and see how it works out.

Attachments

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor