Ian, thanks for this report.

I take away several key points:

1. Your system sounds better with 80C PTC's installed

2. 80C PTCs make for a hassle free oven

3. power and grounding tips

4. insulation from ambient air

I did not know about PTC's. I see they are readily available. I see this as an easy diy project, or even easier if you decide to kit it.

On Andrea's 45MHz crystal I certainly saw a SQ difference with the oven installed. But the oven was a pain to get right as heat was set with a constant resistive load. The self regulating PTC is a win for me. It will be easy for me to try as I built the new clock into its own little thermally stable environment where it is constantly powered. Win! I only need a $10 PTC and a 12v reg.

I take away several key points:

1. Your system sounds better with 80C PTC's installed

2. 80C PTCs make for a hassle free oven

3. power and grounding tips

4. insulation from ambient air

I did not know about PTC's. I see they are readily available. I see this as an easy diy project, or even easier if you decide to kit it.

On Andrea's 45MHz crystal I certainly saw a SQ difference with the oven installed. But the oven was a pain to get right as heat was set with a constant resistive load. The self regulating PTC is a win for me. It will be easy for me to try as I built the new clock into its own little thermally stable environment where it is constantly powered. Win! I only need a $10 PTC and a 12v reg.

@wlowes

You are one of the few people in this community who have experienced oven in the system. My feels are similar to yours.

An oven can not only insulate the changing of the environmental temperature, but also at temperature around the turn point, make the SC-CUT crystal has less temperature coefficient against the dynamic temperature change.

Please go ahead if you want to try the PTC ovens and let us know if you have new updates.

https://www.diyaudio.com/forums/dig...mate-weapon-fight-jitter-714.html#post6764589

Regards,

Ian

You are one of the few people in this community who have experienced oven in the system. My feels are similar to yours.

An oven can not only insulate the changing of the environmental temperature, but also at temperature around the turn point, make the SC-CUT crystal has less temperature coefficient against the dynamic temperature change.

Please go ahead if you want to try the PTC ovens and let us know if you have new updates.

https://www.diyaudio.com/forums/dig...mate-weapon-fight-jitter-714.html#post6764589

Regards,

Ian

Attachments

Last edited:

DRIXO 22.5792MHz frequency stability test with/without an oven

2. With a dual 80°C oven installed, the frequency becomes more stable and doesn’t sensitive that much to the room temperature. The relationship between long term frequency stability and the short term phase noise is still not very clear, however, with the ovens attached to the SC-CUT crystal, the changes to the sound quality are pretty positive. And I believe the more than 1Hz frequency shift should be shown on the phase noise plot if that change is within the measurement time.

Short term and long term stability are different things just like phase noise and Allan Deviation.

The long term stability does not affect the phase noise.

This is the DRIXO oscillator with a PID controlled oven we have built some times ago to compare the phase noise.

There was no phase noise difference between the oscillator with (pink curve) and without (blue curve) the oven.

Just in case the noise floor is a little worse with the oven.

Attachments

I installed a 80C PTC under the 5MHz crystal to be an oven for the WTMC. My clock stays powered constantly. It is mounted inside a wood box fitted with foam and covered in sand. So over time it will stay a constant temperature somewhere approaching 80C.

I concur with Ian regarding a nice little improvement in sound quality. It is not a big change, just a little more of what we see with clock improvements. Natural timbre and less congestion. I could not claim with certainty I could pick it out of an A B test or that I do not imagine it. To my ear its pretty clear and it will stay.

I made a nice little linear 12V ps. It got it's own transformer winding separate with a L7812CV reg.

I concur with Ian regarding a nice little improvement in sound quality. It is not a big change, just a little more of what we see with clock improvements. Natural timbre and less congestion. I could not claim with certainty I could pick it out of an A B test or that I do not imagine it. To my ear its pretty clear and it will stay.

I made a nice little linear 12V ps. It got it's own transformer winding separate with a L7812CV reg.

Attachments

Last edited:

D: Conclusions

1. DRIXO needs at least a couple of hours to reach a stable frequency at room temperature after start. But still very sensitive to the changing of the ambient temperature. Change in 0.3°C can make the frequency immediately shift more than 1Hz.

2. With a dual 80°C oven installed, the frequency becomes more stable and doesn’t sensitive that much to the room temperature. The relationship between long term frequency stability and the short term phase noise is still not very clear, however, with the ovens attached to the SC-CUT crystal, the changes to the sound quality are pretty positive. And I believe the more than 1Hz frequency shift should be shown on the phase noise plot if that change is within the measurement time.

3. The Frequency Tolerance of DUT was measured -32ppm/-15ppm without/with an oven.The Frequency tolerance of the reference commercial OCXO was measured only 0.57ppm under the same testing condition.

Some notes about the oven installation

Ovens may introduce EMI noise into the DRIXO if the circuits are floating. One terminal of each PTC heating element must be connected to the PCB ground to avoid degrading to the low jitter performance.

And I’m still not sure if the aluminum case needs to be connected to the PCB ground.

Ian, you are in Allan Variance (or Allan Deviation) territory.

Most have the opinion that AV does not matter but it is a different way to

characterize Jitter. I know that Jocko felt it did come into the picture but he

never explained exactly how.

TCD

I installed a 80C PTC under the 5MHz crystal to be an oven for the WTMC. My clock stays powered constantly. It is mounted inside a wood box fitted with foam and covered in sand. So over time it will stay a constant temperature somewhere approaching 80C.

I concur with Ian regarding a nice little improvement in sound quality. It is not a big change, just a little more of what we see with clock improvements. Natural timbre and less congestion. I could not claim with certainty I could pick it out of an A B test or that I do not imagine it. To my ear its pretty clear and it will stay.

I made a nice little linear 12V ps. It got it's own transformer winding separate with a L7812CV reg.

@wlowes

Thanks for the update. That's really good. Congratulations!

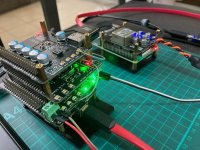

Didn't see your PTC heating elements. Can you post a picture?

Did you ground the PTC to the PCB ground plate?

Regards,

Ian

Getting the most out of WTMC - Oven complete

Ian, thanks for pushing on the ground recommendation. With that completed I believe the impact of oven is more substantial. With PTC grounded listening was a little startling. Less congestion or lots of air would be my impression. In all well recorded cuts but even more impactful on complex classical music.

I took a short cut. Did not follow your approach to ground directly to WTMC ground plane. Instead just created a star ground between the two power supplies. The aluminum case of the chassis is also grounded and all connects to the safety ground that all system is tied into.

Pics of oven approach.

A simple one PTC deal taking advantage of the basic layout. The clock lies face down in a sheet of packing foam with a cutout that the crystal fits into. I put the PTC in the well below the crystal. Then pcb face down, then sheet of emi insulation, then a zip bag of sand and then the wood top to the box. So the clock is sandwiched in a sealed box covered with some mass and the oven directly below. Whole thing is in an Al chassis. So no exposure to external environment, and good vibration/emi insulation. Powered up all the time, the crystal has to get heat soaked. IMHO

Hope that makes sense. I prefer your approach, but this fits my needs. Thanks for a great recommendation.

Ian, thanks for pushing on the ground recommendation. With that completed I believe the impact of oven is more substantial. With PTC grounded listening was a little startling. Less congestion or lots of air would be my impression. In all well recorded cuts but even more impactful on complex classical music.

I took a short cut. Did not follow your approach to ground directly to WTMC ground plane. Instead just created a star ground between the two power supplies. The aluminum case of the chassis is also grounded and all connects to the safety ground that all system is tied into.

Pics of oven approach.

A simple one PTC deal taking advantage of the basic layout. The clock lies face down in a sheet of packing foam with a cutout that the crystal fits into. I put the PTC in the well below the crystal. Then pcb face down, then sheet of emi insulation, then a zip bag of sand and then the wood top to the box. So the clock is sandwiched in a sealed box covered with some mass and the oven directly below. Whole thing is in an Al chassis. So no exposure to external environment, and good vibration/emi insulation. Powered up all the time, the crystal has to get heat soaked. IMHO

Hope that makes sense. I prefer your approach, but this fits my needs. Thanks for a great recommendation.

Attachments

Ian, thanks for pushing on the ground recommendation. With that completed I believe the impact of oven is more substantial. With PTC grounded listening was a little startling. Less congestion or lots of air would be my impression. In all well recorded cuts but even more impactful on complex classical music.

I took a short cut. Did not follow your approach to ground directly to WTMC ground plane. Instead just created a star ground between the two power supplies. The aluminum case of the chassis is also grounded and all connects to the safety ground that all system is tied into.

Pics of oven approach.

A simple one PTC deal taking advantage of the basic layout. The clock lies face down in a sheet of packing foam with a cutout that the crystal fits into. I put the PTC in the well below the crystal. Then pcb face down, then sheet of emi insulation, then a zip bag of sand and then the wood top to the box. So the clock is sandwiched in a sealed box covered with some mass and the oven directly below. Whole thing is in an Al chassis. So no exposure to external environment, and good vibration/emi insulation. Powered up all the time, the crystal has to get heat soaked. IMHO

Hope that makes sense. I prefer your approach, but this fits my needs. Thanks for a great recommendation.

Nice work Wlowes!

Ian, thanks for pushing on the ground recommendation. With that completed I believe the impact of oven is more substantial. With PTC grounded listening was a little startling. Less congestion or lots of air would be my impression. In all well recorded cuts but even more impactful on complex classical music.

I took a short cut. Did not follow your approach to ground directly to WTMC ground plane. Instead just created a star ground between the two power supplies. The aluminum case of the chassis is also grounded and all connects to the safety ground that all system is tied into.

Pics of oven approach.

A simple one PTC deal taking advantage of the basic layout. The clock lies face down in a sheet of packing foam with a cutout that the crystal fits into. I put the PTC in the well below the crystal. Then pcb face down, then sheet of emi insulation, then a zip bag of sand and then the wood top to the box. So the clock is sandwiched in a sealed box covered with some mass and the oven directly below. Whole thing is in an Al chassis. So no exposure to external environment, and good vibration/emi insulation. Powered up all the time, the crystal has to get heat soaked. IMHO

Hope that makes sense. I prefer your approach, but this fits my needs. Thanks for a great recommendation.

Thanks Wlowes for the pictures and experiences sharing.

You did a good job. Congratulations.

Crystal oscillator is a typical low noise application. It's very sensitive to the EMI noise. I found this issue when I did the measurement to SinePi. When the PTC ovens connected, the finial time jitter was increased by 1 to 2 ps under the same condition. And the measured histogram curve indicated that mainly the jitter noise floor was increased. I suspect the floating circuits of the ovens introduced EMI noise while they are next to the crystal. So I connected one of the PTC terminals to the PCB ground, and then, the time jitter measurement result was back to normal. Yes, you are right, after grounding the PTC heating elements, the sound stage clarity was also getting better in my system.

Regards,

Ian

Last edited:

The long term stability does not affect the phase noise.

True, but apparently the audiophiles here are reporting the long term stability also affects the DAC sound. Are you saying that (close in) phase noise is all that matters in an oscillator feeding a DAC? Any evidence on this?

Hello. I i have rpi 4b with ultracapacitor hybrid Power suply, with fifo pi q3 i2s reclocer and self powered two very good clocks. Im tkinking about to change rpi4 onboard clocks. What will be better? https://m.pl.aliexpress.com/item/4000966917203.html?trace=wwwdetail2mobilesitedetail

Or

https://m.pl.aliexpress.com/item/10...cxxzcausmnmn17b98bd604b11791e8423f4889&gclid=

Very thanks for help

Or

https://m.pl.aliexpress.com/item/10...cxxzcausmnmn17b98bd604b11791e8423f4889&gclid=

Very thanks for help

True, but apparently the audiophiles here are reporting the long term stability also affects the DAC sound. Are you saying that (close in) phase noise is all that matters in an oscillator feeding a DAC? Any evidence on this?

I'm saying that long term stability does not affect the phase noise. dot.

I have never argued about listening impressions, but someone has claimed that long term stabilitity should affect the phase noise (measurement and not listening): wrong.

Built and measured:

Asynchronous I2S FIFO project, an ultimate weapon to fight the jitter

Hello. I i have rpi 4b with ultracapacitor hybrid Power suply, with fifo pi q3 i2s reclocer and self powered two very good clocks. Im tkinking about to change rpi4 onboard clocks. What will be better? https://m.pl.aliexpress.com/item/4000966917203.html?trace=wwwdetail2mobilesitedetail

Or

https://m.pl.aliexpress.com/item/10...cxxzcausmnmn17b98bd604b11791e8423f4889&gclid=

Very thanks for help

Hi ! To change the clock on the rpi4 board you can refer to this circuit

??? Raspberry Pi 4B ??? ??? OCXO ???? ????-???

https://www.aliexpress.com/item/1005002991527135.html?spm=a2g0o.detail.1000060.1.4e301d9aNJR0f7&gps-id=pcDetailBottomMoreThisSeller&scm=1007.13339.169870.0&scm_id=1007.13339.169870.0&scm-url=1007.13339.169870.0&pvid=039c6b60-7d9d-4038-8971-c72429dd53b0&_t=gps-id

Last edited:

My OCXO thermostatic clock board successfully turned on!

The sound is great!

This is my other set: Ian Canada FIFOPi

Bridge Pi + XingCore U30 + FIFO Q3 + Reclock Pi + HDMI Pi

盤點個人玩轉樹莓派三大主流播放軟體的一點小經驗 (第54頁) - Mobile01

The sound is great!

This is my other set: Ian Canada FIFOPi

Bridge Pi + XingCore U30 + FIFO Q3 + Reclock Pi + HDMI Pi

盤點個人玩轉樹莓派三大主流播放軟體的一點小經驗 (第54頁) - Mobile01

I don’t see any such claim in #7144 where you quoted. I see only an unsubstantiated claim on SQ, very common in this thread.

You should read carefully:

"And I believe the more than 1Hz frequency shift should be shown on the phase noise plot if that change is within the measurement time."

That's not true by measurement.

1 hour measurement and frequency drift much more than 5Hz, no phase noise difference.

You are confusing phase noise with Allan deviation.

My OCXO thermostatic clock board successfully turned on!

The sound is great!

View attachment 979301

This is my other set: Ian Canada FIFOPi

Bridge Pi + XingCore U30 + FIFO Q3 + Reclock Pi + HDMI Pi

View attachment 979302

盤點個人玩轉樹莓派三大主流播放軟體的一點小經驗 (第54頁) - Mobile01

Double swords together! The ultimate voice appeared!

- Home

- Source & Line

- Digital Line Level

- Asynchronous I2S FIFO project, an ultimate weapon to fight the jitter