MEAN WELL SE 600 Series

[PDF] SE-600-MEAN WELL Switching Power Supply Manufacturer

MEAN WELL SE-600-24 AC to DC Power Supply, Single Output, 24V, 25 Amp, 600W, 1.5"

Amazon.com: MEAN WELL SE-600-24 AC to DC Power Supply, Single Output, 24V, 25 Amp, 600W, 1.5": Industrial & Scientific $ 95.5

[URL]https://images-na.ssl-images-amazon.com/images/I/51nvq7RWoPL._SL1200_.jpg[/URL]

and maybe the SE-600-[B][COLOR=green]48[/COLOR][/B] to [B]BB52[/B] but [B]x2[/B]?

[PDF] SE-600-MEAN WELL Switching Power Supply Manufacturer

MEAN WELL SE-600-24 AC to DC Power Supply, Single Output, 24V, 25 Amp, 600W, 1.5"

Amazon.com: MEAN WELL SE-600-24 AC to DC Power Supply, Single Output, 24V, 25 Amp, 600W, 1.5": Industrial & Scientific $ 95.5

[URL]https://images-na.ssl-images-amazon.com/images/I/51nvq7RWoPL._SL1200_.jpg[/URL]

and maybe the SE-600-[B][COLOR=green]48[/COLOR][/B] to [B]BB52[/B] but [B]x2[/B]?

This Meanwell is 1/3rd the price and 15amps.

MEAN WELL LRS-350-24 350.4W 24V 14.6 Amp Single Output Switchable Power MEAN WELL LRS-350-24 350.4W 24V 14.6 Amp Single Output Switchable Power: Amazon.com: Industrial & Scientific

MEAN WELL LRS-350-24 350.4W 24V 14.6 Amp Single Output Switchable Power MEAN WELL LRS-350-24 350.4W 24V 14.6 Amp Single Output Switchable Power: Amazon.com: Industrial & Scientific

For Hypex or Connex smps's intended for audio you might need a 800watt version for BB and even for Alpha you'll need lots of watts from audiorated smps because continuously they can't deliver much, a Meanwell rated for 130 watt will be powerfull enough for stereo alpha 4r, x2 obviously.

For Hypex or Connex smps's intended for audio you might need a 800watt version for BB and even for Alpha you'll need lots of watts from audiorated smps because continuously they can't deliver much, a Meanwell rated for 130 watt will be powerfull enough for stereo alpha 4r, x2 obviously.

I don’t think the current HYPEX power supply models have suitable output voltages for either Alpha amplifier version.

And yes, with 150 mVpp of ripple better with a big bank of small and cheap caps or expensive big Mundorf MLGO -your choice- I think.

One of the SMPS advantadges is that you will not have problems with the DC at mains and EI/toroidals like me in my house or am I wrong?

One of the SMPS advantadges is that you will not have problems with the DC at mains and EI/toroidals like me in my house or am I wrong?

Last edited:

smps1200a100 might be ok for BB, but could also be too weak, when it can drive them it won't be at 40V or 36V I guess, but lower. A little like what has been reported about transformers here  (the Hypex is unregulated too, but already drops substantial voltage driving a small class D irs2092 mono amp)

(the Hypex is unregulated too, but already drops substantial voltage driving a small class D irs2092 mono amp)

Thanks everybody

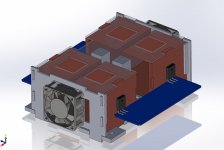

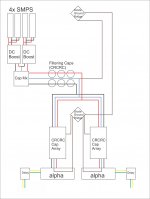

Atatched is a diagram of how I wired the amp.

The Amp is actually two parts (two separate boxes), one power supply and one the amp itself, they connected together via 4 Pin Aviator connectors ( same thing they use in CNC machines)

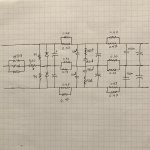

In Power Supply box I have the SMPSs > DC Boost > Cap MX > modified F6 CRCRC Filtering caps and Ground Bridge w CL60.

In Amp Box I have the power > CRCRC Cap Array > Amp, and I have another ground bridge w CL60, that cap arrays and amps are separately connected to it.

I built some amps and pre amps all using laptop SMPS, it may gave me some problems but at the end it always worked out for me, BTW i did not have good luck with regular SMPS , a lot of noise that I couldn't get rid of, with this wiring the first time i powered Alpha on I had to put me ear on the speaker cone to see if it is on or not.

I will provide more detailed pics and diagram later on.

As for the heat sinks I have two fans one for each side X.

BTW, just to make it worse all the boxes are made from wood, no aluminum pieces .

.

Atatched is a diagram of how I wired the amp.

The Amp is actually two parts (two separate boxes), one power supply and one the amp itself, they connected together via 4 Pin Aviator connectors ( same thing they use in CNC machines)

In Power Supply box I have the SMPSs > DC Boost > Cap MX > modified F6 CRCRC Filtering caps and Ground Bridge w CL60.

In Amp Box I have the power > CRCRC Cap Array > Amp, and I have another ground bridge w CL60, that cap arrays and amps are separately connected to it.

I built some amps and pre amps all using laptop SMPS, it may gave me some problems but at the end it always worked out for me, BTW i did not have good luck with regular SMPS , a lot of noise that I couldn't get rid of, with this wiring the first time i powered Alpha on I had to put me ear on the speaker cone to see if it is on or not.

I will provide more detailed pics and diagram later on.

As for the heat sinks I have two fans one for each side X.

BTW, just to make it worse all the boxes are made from wood, no aluminum pieces

Attachments

Last edited:

Beautiful work, Aatto. I thought those "wood" panels were 3d printed like much of your stuff. It would be very instructive to see the power supply box with DC step up and cap Mx. Which SMPS are you using (HP?) and which cap Mx are you using? That's interesting that you have multiple diode bridge ground loop breakers. Usually there is only one between dirty earth ground and "clean" 0v amp power ground. Lots of CRC and CRCRC certainly helps. It's a very compact implementation - how warm does the fan cooled inside of the case get?

We have a lot of forced convection CPU coolers going on. We have linear as well as SMPS. We have a lot of custom hand made one of a kind cases. It’s really a nice diversity of amp styles. Rather than all 4U/5U boxes with fins on the side, we get to see some pretty neat stuff.

Would you like to share the Alpha 20 logo artwork

Hello Aatto,

My compliments on a nice build, Happy listening (I wish I was at the same stage)

I very much like the design of the Alpha 20 logo / text on the front plate, would you like to share the artwork?

Grtz

Bert

Hello Aatto,

My compliments on a nice build, Happy listening (I wish I was at the same stage)

I very much like the design of the Alpha 20 logo / text on the front plate, would you like to share the artwork?

Grtz

Bert

Attachments

Aatto,,

Fantastic work very neat and generous cap bank!

One day try using a CRCRC linear supply and compare the sound.

Thanks for building the ALPHA.

HD

Thanks Hugh

This was supposed to be my test supply, but i got good results so i will stick to this for now but since it's a class A and tends to run hot i m planning to get an aluminum case with a dedicated linear supply inside, will definitely do A/B comparison.

Last edited:

thanks everybody for your interest.

I attached some pix, hope it helps. let me know if you need more details.

main CRCRC filter, CRCRC cap array and logo is included.

I do not own a 3d Printer, what you saw so far is all laser cut/engraved wood panels, best 400$ i ever spent i would strongly suggest it.

well so far i managed to run the amp for a few hours and it gets pretty hot, heatsinks got to 150F, so for now i m running it opened top ( top less !) which i can hear the fans now, i used hot glue for some components and it start to loose its solid state ! so I crank down the voltage to +-22.5 (was 24.5) and will keep an eye on it but I will eventually switch to an aluminum case.

I attached some pix, hope it helps. let me know if you need more details.

main CRCRC filter, CRCRC cap array and logo is included.

...I thought those "wood" panels were 3d printed like much of your stuff....

I do not own a 3d Printer, what you saw so far is all laser cut/engraved wood panels, best 400$ i ever spent i would strongly suggest it.

...how warm does the fan cooled inside of the case get?...

well so far i managed to run the amp for a few hours and it gets pretty hot, heatsinks got to 150F, so for now i m running it opened top ( top less !) which i can hear the fans now, i used hot glue for some components and it start to loose its solid state ! so I crank down the voltage to +-22.5 (was 24.5) and will keep an eye on it but I will eventually switch to an aluminum case.

Attachments

Last edited:

The best solution I've seen is the one that Troels implemented: semi active(digital), semi passive

[/QUOTE]

the easiest way to do similar is using HT receiver in x-stereo or multi-channel mode. In that case all L and all R outputs play same (stereo) signal so each amp can drive its own driver with or without x-over, Additional benefit is adjustable channel level, so no L-pads.

[/QUOTE]

the easiest way to do similar is using HT receiver in x-stereo or multi-channel mode. In that case all L and all R outputs play same (stereo) signal so each amp can drive its own driver with or without x-over, Additional benefit is adjustable channel level, so no L-pads.

thanks everybody for your interest.

I attached some pix, hope it helps. let me know if you need more details.

main CRCRC filter, CRCRC cap array and logo is included.

I do not own a 3d Printer, what you saw so far is all laser cut/engraved wood panels, best 400$ i ever spent i would strongly suggest it.

well so far i managed to run the amp for a few hours and it gets pretty hot, heatsinks got to 150F, so for now i m running it opened top ( top less !) which i can hear the fans now, i used hot glue for some components and it start to loose its solid state ! so I crank down the voltage to +-22.5 (was 24.5) and will keep an eye on it but I will eventually switch to an aluminum case.

150F is 65C and that’s hot enough to cook steak with!

Probably making it so compact and your heatsinks are just pure copper blocks and fins and not heat pipe spreaders. That PSU is impressive and I j ew it had to be more complicated than I thought. No wonder you don’t have any noise - look at all that filtering CRC - especially with the R on the 0v or GND bus. Maybe some more cents in tip and bottom panel with laser cutting will help cooling.

150F is 65C and that’s hot enough to cook steak with!

Probably making it so compact and your heatsinks are just pure copper blocks and fins and not heat pipe spreaders. That PSU is impressive and I j ew it had to be more complicated than I thought. No wonder you don’t have any noise - look at all that filtering CRC - especially with the R on the 0v or GND bus. Maybe some more cents in tip and bottom panel with laser cutting will help cooling.

you are right, the amp box is too small and crowded, it prevents air circulation i removed the top and now it is 95F ! huge difference, i could add more vents but it is a 3mm MDF and will results in a weak construction (the copper heatsinks are HEAVY ). i have to put more thoughts into this.

BTW the second set of CRCLCRC filter you see in PSU is for trafo, it's +-40v for my FH9.

My theory behind this was that high mf caps are expensive and it would be cheaper to have smaller caps (6800 to 10mf) but have better filtering path.

So i m listeing to this amp for a few hours now and it handles anything i throw at it, but the best experience i had was with "wish you were here" the acoustic guitar is just shine through, long story short, it put a smile on my face

Thanks

A.

- Home

- Amplifiers

- Solid State

- Aksa Lender P-MOS Hybrid Aleph (ALPHA) Amplifier