Did you replace the tweeter wire on any of the speakers? I have put tweeter kits in an SMGa and MGII. Also repaired delamination in both. Putting in new tweeters was not that hard to do. They do have the proper wire. You can order repair kits with the proper adhesive from them. Their instructions talk about repairing rips with Scotch tape. If you replace tweeters try to go light with the Scotch 30 over the top of the wire.

weird are there instructions of patching up mylar with tape ? i never seen one im interested what they say about that.

The way the magnepans reach up to 18-10 khz is by the tension on the foil, if it is sloppy it cuts as low as 14khz-16khz. that might be it. weight might also be a problem but i dont think you added soooo much glueespecially in the tweeter area

Its taut not sloppy. I've got almost full tension in the middle of the maggie (i bend the frame to give me some slack to work with).

The top part (above the dampener) is not so tight as i couldn't get enough slack. It's less thight but not sloppy i would say.

I did put 2 layers of 6mu mylar, in some places 3 layers (where there was a gap) so i'm not sure how much glue is too much bit i dit make sure it is not going to tear.

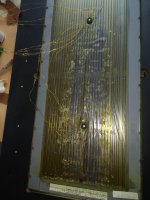

I'll post two pictures with the before and after so people can have a view. BTW the "wrinkles" you might see are not wrinkles. It's the top layer of mylar that isn't stretched entierly. The underlying mylar is tensioned.

one person said it might be a corroded tweeter and suggested to measure the resistance. Will do that next, hopefully that's it, but i'm not too sure.

Attachments

Its taut not sloppy. I've got almost full tension in the middle of the maggie (i bend the frame to give me some slack to work with).

The top part (above the dampener) is not so tight as i couldn't get enough slack. It's less thight but not sloppy i would say.

I did put 2 layers of 6mu mylar, in some places 3 layers (where there was a gap) so i'm not sure how much glue is too much bit i dit make sure it is not going to tear.

I'll post two pictures with the before and after so people can have a view.

one person said it might be a corroded tweeter and suggested to measure the resistance. Will do that next, hopefully that's it, but i'm not too sure.

that is a mess to be honest

Right, looks like thay feel over...cup air just right..ripout..if it would hit on one side it would have been less......

oh well one good thing ...theres a pr mg 1.4 just pop up for sale an I was thinking about them...but I for got there two buttes per speakers...I well pass.to my ear the best sounding magnepans are one buttes...my mg 1c panels are the same size as the 1.4..one buttes...freaky......good luck

oh well one good thing ...theres a pr mg 1.4 just pop up for sale an I was thinking about them...but I for got there two buttes per speakers...I well pass.to my ear the best sounding magnepans are one buttes...my mg 1c panels are the same size as the 1.4..one buttes...freaky......good luck

Are these comments for the first or second picture. I was actually hoping the second picture would look relatively ok.

Some options I have:

1. I can retry tensioning the upper part of the Mylar. That’s actually the only part that wasn’t fully tensioned.

2. Remove all the mylar and tension a new Mylar sheet? How difficult will that be? I can only get 6um mylar, from a strength perspective, would this be a problem?

3. Can I use a heatgun to shrink the mylar a bit or is that a bad idea?

I've had some contact with Magnepan. Getting a pair of drivers here is going to cost me 1000 dollars (ex VAT). So that's not really an option. I might be able to get a pair of SMGa for 250 euro, but i'm feeling like that would be a step down... I can use them as is, (as i mentioned, it's less noticeable when you use them in a pair). When another pair comes along (or a single speaker) i can grab that one.

I got them for 80 euro's and spend an addition 40 euro's on materials, so I havn't lost too much money on it. Would be great if I could get them to work to the fullest extent though.

Some options I have:

1. I can retry tensioning the upper part of the Mylar. That’s actually the only part that wasn’t fully tensioned.

2. Remove all the mylar and tension a new Mylar sheet? How difficult will that be? I can only get 6um mylar, from a strength perspective, would this be a problem?

3. Can I use a heatgun to shrink the mylar a bit or is that a bad idea?

I've had some contact with Magnepan. Getting a pair of drivers here is going to cost me 1000 dollars (ex VAT). So that's not really an option. I might be able to get a pair of SMGa for 250 euro, but i'm feeling like that would be a step down... I can use them as is, (as i mentioned, it's less noticeable when you use them in a pair). When another pair comes along (or a single speaker) i can grab that one.

I got them for 80 euro's and spend an addition 40 euro's on materials, so I havn't lost too much money on it. Would be great if I could get them to work to the fullest extent though.

Last edited:

for option 1 I meant:

1. I can retry repairing the upper part of the Mylar and put proper tension. That’s actually the only part that wasn’t fully tensioned. Perhaps i just have to remove the magnets from the mylar frame and do a proper fix (i.e. remove tuning discs etc..). That's going to be quite the project, but it will avoid me from putting a new sheet.

The reason i would do that instead of a new mylar sheet is:

1. i don't have a jig

2. I can get the tension to match closest to the original.

Does it make sense? or is it better to put a new foil if i'm going to remove the magnets and tuning discs anyway.

1. I can retry repairing the upper part of the Mylar and put proper tension. That’s actually the only part that wasn’t fully tensioned. Perhaps i just have to remove the magnets from the mylar frame and do a proper fix (i.e. remove tuning discs etc..). That's going to be quite the project, but it will avoid me from putting a new sheet.

The reason i would do that instead of a new mylar sheet is:

1. i don't have a jig

2. I can get the tension to match closest to the original.

Does it make sense? or is it better to put a new foil if i'm going to remove the magnets and tuning discs anyway.

the foil is ******, so are the wires, so a complete new refoil might be the only option, and only an option if you keep in mind they are lost. Or keep them as is.

you need 12 micron mylar to do this proper, a stretch jig for the mylar, and pref a stretch jig for the wires, although you might get away without one if you have the time to do it without and can work clean and precise . wires you can get from magnepan.

but i must admit is it a prety big undertaking, but whats there to lose ? you should only do it if you will trow them away otherwise.

you need 12 micron mylar to do this proper, a stretch jig for the mylar, and pref a stretch jig for the wires, although you might get away without one if you have the time to do it without and can work clean and precise . wires you can get from magnepan.

but i must admit is it a prety big undertaking, but whats there to lose ? you should only do it if you will trow them away otherwise.

Lot people think the SMGa..not the smg....is the best speaker magnepan made...I have had about 15 pr of maggys in 35 years...5-6 pr were SMGa,s

Magic speakers! ......" highly recommend"......only speaker magnepan made with a series crossover took 30 years ....now thats all thay use....it was a shocker for me... was to see there only like 4" diff in highth in panel size for the mg1.4 an the smga....

Magic speakers! ......" highly recommend"......only speaker magnepan made with a series crossover took 30 years ....now thats all thay use....it was a shocker for me... was to see there only like 4" diff in highth in panel size for the mg1.4 an the smga....

Lot people think the SMGa..not the smg....is the best speaker magnepan made...I have had about 15 pr of maggys in 35 years...5-6 pr were SMGa,s

Magic speakers! ......" highly recommend"......only speaker magnepan made with a series crossover took 30 years ....now thats all thay use....it was a shocker for me... was to see there only like 4" diff in highth in panel size for the mg1.4 an the smga....

but doesn't the 1.4 go lower in frequency?

the foil is ******, so are the wires, so a complete new refoil might be the only option, and only an option if you keep in mind they are lost. Or keep them as is.

you need 12 micron mylar to do this proper, a stretch jig for the mylar, and pref a stretch jig for the wires, although you might get away without one if you have the time to do it without and can work clean and precise . wires you can get from magnepan.

but i must admit is it a prety big undertaking, but whats there to lose ? you should only do it if you will trow them away otherwise.

My understanding was that the wires don't have to be perfectly in the middle, as long as they are in between the magnets, i can get new wires, that should not be as costly as the drivers.

The other question i have is, fixing the mylar is really no option? It's a hell of a lot easier to get the appropriate tension, i'll just remove the dampeners, bend the frame and stick the mylar together (as i did before, but just better).

Lastly, where do i get 12 micron mylar? I can try to tension it, but if it only works with 12 micron, i'll need to source that first.

I'm not going to throw them away, I'm guessing that 1 good panel is still going to be worth more than 100 euro regardless.

p.s. i'm not trying to know it better.... just trying to see how i can improve this unit as best I can.

Last edited:

4 inch higher, what about the baffle size ? it dictates low end much. i do think the smga is one of the best bang for buck thats for sure. i must say im not much liking the newer ones, they sound more analytic or just bright. i compared one 0.7 por the 1.7 not sure anymore against my quads esl63 and the quads even won in the low end... witch was a shocker for me.

The SMGa .....you have to be there.Dynaco ST70 an the SMGa..I sand by..98% of all magnepas...Most say it the series crossover.....see pic...Sweet tone... took 30 years to get back to it.. but the qribbon killet it...well for this one man!

Magnestand ....dose a mod ..All wood frames...series crossover ...

Mr Peter Gunn....with his mod ...Some say the SMga is as good as ESL speakers...what a look....Mr.Gunn SMGa speaker......just saying

I did the 1.7.....OMG sold them took a loss an glad to do it!....MMg best one with the Qribbon...this sound IS not for me ears....it for the people that never heard the older ones...All just one mans finding....have fun good luck

Magnestand ....dose a mod ..All wood frames...series crossover ...

Mr Peter Gunn....with his mod ...Some say the SMga is as good as ESL speakers...what a look....Mr.Gunn SMGa speaker......just saying

I did the 1.7.....OMG sold them took a loss an glad to do it!....MMg best one with the Qribbon...this sound IS not for me ears....it for the people that never heard the older ones...All just one mans finding....have fun good luck

Attachments

Lastly, where do i get 12 micron mylar? I can try to tension it, but if it only works with 12 micron, i'll need to source that first.

Electrostatic Speaker Membrane Dupont Mylar C 12um 20M | eBay

Electrostatic Speaker Membrane Dupont Mylar C 12um 40M | eBay

Strange prices, 20 m is more then 40 m. This is not the same type of Mylar that Magnepan use, it is no longer produced.

Last edited:

WirneX.....one of the mods Mr Gunn dose with the old are new Magnepans .....set them up with the Mylar faceing the back.....have you tried this with your panels?...did you post info on your findings...did I miss them...thanks

if you do the high frequency will look worse, due to cavity resonance i assume. i tried series as well as parallel filtering and i dont see any reason why the series should sound better. it is cheaper thats for sure

Electrostatic Speaker Membrane Dupont Mylar C 12um 20M | eBay

Electrostatic Speaker Membrane Dupont Mylar C 12um 40M | eBay

Strange prices, 20 m is more then 40 m. This is not the same type of Mylar that Magnepan use, it is no longer produced.

i always buy the 40

what special kind of mylar did they used ?

what special kind of mylar did they used ?

They will not tell you! I spoke to Wendell Diller and he was as always very tight about giving any information. Besides, they will not sell you any Mylar.

As already mentioned, for good high frequency reproduction the Mylar should be rahter tightly tensioned. For bass, it is the opposite or even better to use a suitable tension for a desired low frequency response.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- How to fix a tear in a Magnepan 1.4

![images[1].png](/community/data/attachments/620/620048-ec890428bb503f05845612198ddfef24.jpg)

![mmg17[1].jpg](/community/data/attachments/620/620085-617492359f14961eab60ba8887490237.jpg)