No, I don't, but some people do. I showed this because I consider spikes to be a downright stupid idea.

Ok, now I'm with you

Best regards!

thank you guys

i unscribe to this discussion

but until closed by moderators, watch for continued postulating and bloviating on the subject

next dead horse - best speaker wire?

thank you guys

i unscribe to this discussion

That's preferable to another hissy fit.

+1That's preferable to another hissy fit

Another for the list.

I have frequently observed that the most trivial issues in speaker building attract the most attention!

Aware that I am locking the gate after the horse (diypass) has bolted, here's my take on it.

The real idea is really to avoid scratching your furniture. We assume a cabinet is solidly designed. With consideration to mass distribution, I just use rubber feet. Quite how some companies can charge £5 for a bit of rubber that might as well be replaced with halved squash balls or bicycle inner tube, here's what I do.

The idea is the rattles of the cabinet don't combine with the rattles of the furniture it rests on. All a vague science, IMO.

Aware that I am locking the gate after the horse (diypass) has bolted, here's my take on it.

The real idea is really to avoid scratching your furniture. We assume a cabinet is solidly designed. With consideration to mass distribution, I just use rubber feet. Quite how some companies can charge £5 for a bit of rubber that might as well be replaced with halved squash balls or bicycle inner tube, here's what I do.

The idea is the rattles of the cabinet don't combine with the rattles of the furniture it rests on. All a vague science, IMO.

Attachments

To under stand spikes and even rubber feet you need to consider the panels vibration modes. Like a room, a panel of a speaker enclosure will support standing waves of different wave lengths. The wave lengths will be depending on the dimensions and shape of the panels. Put a support at a node and the speaker more or less will not transmit any energy to the floor. It will effectively be decoupled from the floor and the panel will vibrate as it would if suspended. Place a support at an antinode and, depending whether the support is ridged (spike) or dissipative (rubber foot) more or less energy associated with the particular panel frequency will be transmitted to the floor and amplifier, juts a the sound from a tuning fork is amplified when the tip is placed in contact with a larger surface. The rubber feet will minimize this transfer, spikes will maximize it. Of course, where nodes and antinodes are located, as well as places in between means that different frequencies will be coupled or decoupled to the floor but different degrees. The most effect way to isolate a speaker from the floor and to damp the panel vibration is through placing the speaker on a dissipative pad that covers the entire bottom. There has actually been research done on this many years ago, but since it went against the commercial interests of the spike manufactures it never really came to light. Sort of like the research done on speaker cables that cost a lot and don't really do anything.

The most effect way to isolate a speaker from the floor and to damp the panel vibration is through placing the speaker on a dissipative pad that covers the entire bottom. There has actually been research done on this many years ago, but since it went against the commercial interests of the spike manufactures it never really came to light.

I have used spikes and hard(ish) rubber feet but found that the cabinet flexed (u frame subs) I cut up some old sorbothane insoles which completely solved the problem. An inventor came up with a shaving foam that caused razor blades to last many times longer than usual, it never went into production the patent was bought by blade manufacturers

Heck, that's nothing. Years ago, a Harvard prof* wrote a whole book explaining how you could take something like Saran-Wrap and make a loudspeaker out of it with infinitesimal distortion... instead of the old Rice-Kellogg design which shakes heavy pieces of cardboard in the shape of a cone.An inventor came up with a shaving foam that caused razor blades to last many times longer than usual, it never went into production the patent was bought by blade manufacturers

See much of that now? Bet you don't. Just some odd folks like Martin Logan and the crew at the Planar forum are interested.

Those Saran-Wrap speakers DO NOT need spikes.

B.

* F. V. Hunt

Last edited:

Ground up tyres are also used to create a layer of rubber over pavement or concrete.

One of many: Enviropaving - Rubber paving with 100% recycled tire rubber

dave

One of many: Enviropaving - Rubber paving with 100% recycled tire rubber

dave

To prevent vibrations from the speaker being transmitted to the floor (book shelve or whatever it is positioned on) common cheap vibration dampers in rubber can be effective. To keep in mind: Being effective means to choose vibration dampers which when loaded reach a natural resonance of their own which is at least the lowest frequncy the speaker can play divided by root (2). So if it is a potent sub going down to 20 Hz: 20/root(2) = 20/1,41 = 14 Hz. (Natural frequency should preferably be 2 octaves below lowest played frequency.)

For 90% / 20 dB isolation of 20 Hz that means about 8 mm deflection (”compression”) for the rubber feet. That is actually quite a lot, main speakers are much easier in practice, if crossed at 80 Hz one would strive for (at least) 1 mm deflection. In the link, on page 1-3 you find what is of importance to choose the correct vibration damper. Deflection (”compression”) depends on rubber hardnesss, area under load, the foots form factor and of course the mass applied (speaker weight/foot). Proper loading is very important, if the speaker is too leight weight versus the vibration dampers properties, it may turn out quite useless to isolate bass frequencies.

Link: http://www.tme.eu/se/Document/fb716885927a5b9b8a7f6be51b7da173/DVA-EN.pdf The cone shaped ones should be the best normal choice for ”normal weight speakers”.

For 90% / 20 dB isolation of 20 Hz that means about 8 mm deflection (”compression”) for the rubber feet. That is actually quite a lot, main speakers are much easier in practice, if crossed at 80 Hz one would strive for (at least) 1 mm deflection. In the link, on page 1-3 you find what is of importance to choose the correct vibration damper. Deflection (”compression”) depends on rubber hardnesss, area under load, the foots form factor and of course the mass applied (speaker weight/foot). Proper loading is very important, if the speaker is too leight weight versus the vibration dampers properties, it may turn out quite useless to isolate bass frequencies.

Link: http://www.tme.eu/se/Document/fb716885927a5b9b8a7f6be51b7da173/DVA-EN.pdf The cone shaped ones should be the best normal choice for ”normal weight speakers”.

Given the talk about coupling box resonance to the floor, one can go a long way towards making this moot by building a box with a low resonance signature.

And when one talks about transmitting resonances to the floor, is not the lowest resonance of the box panel being coupled the metric to use when figuring out the decoupling frequency of any footer?

dave

And when one talks about transmitting resonances to the floor, is not the lowest resonance of the box panel being coupled the metric to use when figuring out the decoupling frequency of any footer?

dave

Perhaps another "faith" among audiphiles that just won't die...OK for angling up to for beaming effects...Note: our bed upstairs seemingly lost its little caster wheel for the bed-frame...years ago it would seem. The remaining post/spike bored a hole clear thru the ceramic tiles & about 20mm into the concrete underneath. Almost as if someone took a 20mm wide ceramic drill-bit, & drilled down some 20mm. Think about that as you line up your fancy razor sharp isolating "locating spikes".

--------------------------------------------------------------------Rick..............

--------------------------------------------------------------------Rick..............

This thread is becoming HUGE!

Ground up tyres and cork are the main ingredients of Regupol K225 acoustic floor insulation, which goes under the pretty wooden flooring:

But don't nail it down or simply stops working.

I stick it to the inside of cabinets, but it will doubtless work just as well on the outside:

Thinking about all this, you might as well rest your speakers on a big bit of packing foam or spongey stuff you often find in packaging. The speakers must almost float on air. It's not rocket science, is it!

Were the couple upstairs very much in love?Perhaps another "faith" among audiphiles that just won't die...OK for angling up to for beaming effects...Note: our bed upstairs seemingly lost its little caster wheel for the bed-frame...years ago it would seem. The remaining post/spike bored a hole clear thru the ceramic tiles & about 20mm into the concrete underneath. Almost as if someone took a 20mm wide ceramic drill-bit, & drilled down some 20mm. Think about that as you line up your fancy razor sharp isolating "locating spikes".

Ground up tyres and cork are the main ingredients of Regupol K225 acoustic floor insulation, which goes under the pretty wooden flooring:

But don't nail it down or simply stops working.

I stick it to the inside of cabinets, but it will doubtless work just as well on the outside:

Thinking about all this, you might as well rest your speakers on a big bit of packing foam or spongey stuff you often find in packaging. The speakers must almost float on air. It's not rocket science, is it!

Member

Joined 2009

Paid Member

+1 to no spikes, no beaks on top and no little wooden blocks to keep your speaker cables off the floor either. Unless your carpet is very thick and bouncy or you want to avoid your speakers creating a flat patch in the carpet - in this case spikes would be good and I'd go with two at the front corners and two at the back - if the floor wasn't level then one at the back-middle.

Last edited:

If you really want to isolate a speaker cabinet from the room, you can buy compressed gas systems that float any audio equipment (including electronics) from the floor on a steam of air! With electronics, it's considerably cheaper to put it all in the next room.

But this is all a bit prissy IMO.

The opposite approach is to fix a speaker to the huge mass of solid wall boundaries. This works well in isolation, but your neighbours might not enjoy subwoofers coupled to the whole apartment block!

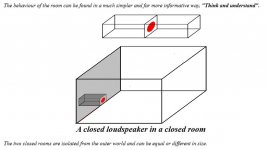

Nobody ever gets this, but Steen Duelund suggested that anything you do to a speaker cabinet might as well apply to the listening room too. So you have the same issues in your room as a cabinet. To give an example, if "Golden Ratio" and panel damping is good for a cabinet, might it not be good for the room too? Well, a friend of mine has lined his brick-built home cinema with 3" of rockwool. The speakers are built into the walls, the carpet is deep wool. It sounds good.

But this is all a bit prissy IMO.

The opposite approach is to fix a speaker to the huge mass of solid wall boundaries. This works well in isolation, but your neighbours might not enjoy subwoofers coupled to the whole apartment block!

Nobody ever gets this, but Steen Duelund suggested that anything you do to a speaker cabinet might as well apply to the listening room too. So you have the same issues in your room as a cabinet. To give an example, if "Golden Ratio" and panel damping is good for a cabinet, might it not be good for the room too? Well, a friend of mine has lined his brick-built home cinema with 3" of rockwool. The speakers are built into the walls, the carpet is deep wool. It sounds good.

Attachments

Last edited:

Judging from Townshend’s video, I believe these work well. One can note the speaker with his gadget attached rocks a bit back and forth at a slight push. That is a sign that the speaker is floating (or close to) versus the floor, speaker vibrations are then well isolated and not being mechanically transmitted so much, or at all. Video: How to isolate speakers from ground borne vibration: Seismic Isolation Podium for speakers - YouTube

The price tag is steep though, GBP 99:- per pod, or USD 129:- / EUR 111:-. http://www.townshendaudio.com/pricelist/Retail Pricelist June 2016 - Townshend.pdf If you don’t crave for aestetich looks, you can buy Sylomer material doing the same job for a fraction of the cost. (Google Sylomer or the manufacturer Getzner.) If a thread would be beneficial for you, common rubber vibrations dampers, costing a dollar or two, may be good enough. These have a higher hardness than Sylomer (which is a cellular polyurethane elastomer with little fatiguing over time) so aiming for a very low natural frequency (= isolating bass vibrations well) is not easily done combined with a low weight speaker, < 45 kg / 100 lbs or so. The lighter the speaker, the harder to isolate low frequencies with a solid rubber foot. Isolating from 30 Hz and upwards shouldn’t be a problem though, one needs roughly 3 mm deflection for 90% / 20 dB isolation, 5 mm gives about 95% / 34 dB isolation. At 20 Hz it is ”only” about 9,5 and 14 dB for 3 and 5 mm respectively. (Check ut the diagram in the link I posted above. Again, coned ones like DVA.6 or DVA.7 should be the best type for most.)

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Best spikes position under loudspeaker