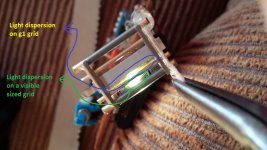

That 6JC6 grid is incredible. Can look right thru it like a crystal.

A real frame grid, indeed! That look is what exactly has to be expected.

Best regards!

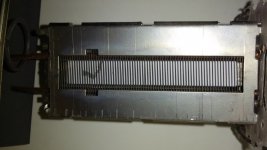

The E130L frame grids bring up another mystery as to how frame grids are made. Specifically, how the tiny wires are bonded to the support rods.

In the E130L, the screen grid has a glossy black coating along the support rods. It almost looks like a coating of glue. There is a small strip of something added to the outside edge of the support rods also, and it's "glued" over with the black stuff. However I don't see anything similar for the grid1 support rods, they -look- like copper.

I filed the support rod ends and they are made of a shiny steel or nickel like material. A magnet finds them only slightly magnetic however, so not nickel or steel. Maybe some stainless alloy.

While there are vacuum usable "glues", usually for fixing leaks, I'm sure no "glue" would stand up to tube operation temperatures. So I wonder what's being used here.

If I had to solve the delicate wire bonding problem for frame grids myself, I would just dip the rods into an electroplating solution and plate some metal over the wires on the rods. It's not too hard to get a "carbon black" surface by increasing the plating current temporarily to deposit metal too fast. This may have been done to improve the heat radiating properties of the grid2 support rod. Not sure how they would get the glossy black surface though, maybe they just swept a hot flame over it.

The small strips along the outside of the grid2 support rod (and maybe the grid1 support rod too, I just can't see it yet without further tear-down) may be a mechanism for aligning the grids (wires). They might be precision ground to align the grid wires by setting snugly on the mica supports. But then how did they attach the strips to the support rods without destroying the delicate frame grid?

Well, I'm thinking in terms of how one would construct a small scale tube production machine these days. Today, we have 3D (metal or other) printers that could make grid winding forms and plate pressing forms. Electroplating should be easy enough (for grid wire attachment and grey or black plates). A small hydraulic press available for making plates. Continuously (micro-) position-able stepper motors for precise grid winding or tube positioning in flames. A variable current, tiny spot welder. Some Basic control software for each operation. A two stage vacuum pump (Harbor Freight) and optional diffusion pump (Ebay). A small induction heater for firing getters. Modern cathodes don't need heaters and can be made by gel thin film electroplating.

A small tube operation could fit on two or three benches for a single worker. Of course output quantity might be only one or two tubes per day with all the setup and operation times for each step. Unless multiple workers are involved at each functional station continuously. Get the local audio club to come over and run off 50 custom tubes on the weekend.

In the E130L, the screen grid has a glossy black coating along the support rods. It almost looks like a coating of glue. There is a small strip of something added to the outside edge of the support rods also, and it's "glued" over with the black stuff. However I don't see anything similar for the grid1 support rods, they -look- like copper.

I filed the support rod ends and they are made of a shiny steel or nickel like material. A magnet finds them only slightly magnetic however, so not nickel or steel. Maybe some stainless alloy.

While there are vacuum usable "glues", usually for fixing leaks, I'm sure no "glue" would stand up to tube operation temperatures. So I wonder what's being used here.

If I had to solve the delicate wire bonding problem for frame grids myself, I would just dip the rods into an electroplating solution and plate some metal over the wires on the rods. It's not too hard to get a "carbon black" surface by increasing the plating current temporarily to deposit metal too fast. This may have been done to improve the heat radiating properties of the grid2 support rod. Not sure how they would get the glossy black surface though, maybe they just swept a hot flame over it.

The small strips along the outside of the grid2 support rod (and maybe the grid1 support rod too, I just can't see it yet without further tear-down) may be a mechanism for aligning the grids (wires). They might be precision ground to align the grid wires by setting snugly on the mica supports. But then how did they attach the strips to the support rods without destroying the delicate frame grid?

Well, I'm thinking in terms of how one would construct a small scale tube production machine these days. Today, we have 3D (metal or other) printers that could make grid winding forms and plate pressing forms. Electroplating should be easy enough (for grid wire attachment and grey or black plates). A small hydraulic press available for making plates. Continuously (micro-) position-able stepper motors for precise grid winding or tube positioning in flames. A variable current, tiny spot welder. Some Basic control software for each operation. A two stage vacuum pump (Harbor Freight) and optional diffusion pump (Ebay). A small induction heater for firing getters. Modern cathodes don't need heaters and can be made by gel thin film electroplating.

A small tube operation could fit on two or three benches for a single worker. Of course output quantity might be only one or two tubes per day with all the setup and operation times for each step. Unless multiple workers are involved at each functional station continuously. Get the local audio club to come over and run off 50 custom tubes on the weekend.

Last edited:

Not a TV tube, but...

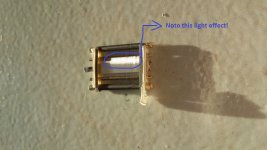

... since this therad have too many good tube dissections, yesterday I dissected a monster of gm tube: the E810F. For a sake of putting things into perspective, and the "normal curiosity"

I attached several photos I made with cellphone camera, so please thake this into account (the resolution is limited, and I compressed the photos for forum usage).

With naked eye, with some lens and the cellphone camera, i'm unable to see any wire in g1! Is a very small sized wiring! Perhaps the grid wire size is comparable with EC8010: VinylSavor: EC8010

Is a very small sized wiring! Perhaps the grid wire size is comparable with EC8010: VinylSavor: EC8010

But I don't imaginated that one TV tube, the 6JC6 that smoking-amp has mentioned, have a such small gride wire

In next post I show a Matsushita PL509, a EF86 and a 3V4 DHP miniature tube for a comparision (for assuruing my camera possibilities)

... since this therad have too many good tube dissections, yesterday I dissected a monster of gm tube: the E810F. For a sake of putting things into perspective, and the "normal curiosity"

I attached several photos I made with cellphone camera, so please thake this into account (the resolution is limited, and I compressed the photos for forum usage).

With naked eye, with some lens and the cellphone camera, i'm unable to see any wire in g1!

But I don't imaginated that one TV tube, the 6JC6 that smoking-amp has mentioned, have a such small gride wire

In next post I show a Matsushita PL509, a EF86 and a 3V4 DHP miniature tube for a comparision (for assuruing my camera possibilities)

Attachments

I lost the 3V4 filament... of course, too small wire gauge...

of course, too small wire gauge...

The EF86 have a more normal sized grid 1, and makes the E810F looks like a alien-made g1

The first photo is the 40KG6/PL509

The EF86 have a more normal sized grid 1, and makes the E810F looks like a alien-made g1

The first photo is the 40KG6/PL509

Attachments

Last edited:

Probably, I'm not up on the latest feedthrough stuff. There used to be different alloy wire for different types of glass. Different thermal expansion rates.

That E810F, with 50,000 gm, surely has tiny tiny grid1 wire.

6JC6 is only 16000 gm, although it's only half the size (Wattage) tube. DC Current rating 20 mA versus 50 mA for the E810F.

I have an E55L/8233 tube here that I can see thru with a magnifying glass. Looks like grid1 wire is intermediate between the 12HL7 and the 6JC6. 45000 gm but also 10 watt size like the 12HL7 (21000 gm). Still working, so no hammer for it today.

If you have a paper scanner, that is what I used for the high resolution grid pics. Have to get the grid fairly close to the glass surface. 2400 DPI finally resolved the 6JC6 wires. (best the scanner could do!)

Hmm, looks like those E810F are around $30. Ouch! 6JC6 is on the Dollar List at ESRC.

.

That E810F, with 50,000 gm, surely has tiny tiny grid1 wire.

6JC6 is only 16000 gm, although it's only half the size (Wattage) tube. DC Current rating 20 mA versus 50 mA for the E810F.

I have an E55L/8233 tube here that I can see thru with a magnifying glass. Looks like grid1 wire is intermediate between the 12HL7 and the 6JC6. 45000 gm but also 10 watt size like the 12HL7 (21000 gm). Still working, so no hammer for it today.

If you have a paper scanner, that is what I used for the high resolution grid pics. Have to get the grid fairly close to the glass surface. 2400 DPI finally resolved the 6JC6 wires. (best the scanner could do!)

Hmm, looks like those E810F are around $30. Ouch! 6JC6 is on the Dollar List at ESRC.

.

Last edited:

Will be interesting to know the E55L/8233 internals!

"Hmm, looks like those E810F are around $30. Ouch"

At least this E810F sample are a defective one

I have 2 E810F working examples; very difficult to tame oscillations, even at tracer. Is almost impossible to test in triode mode, even with plenty of stopper resistors and ferrite beads. But I have made it work in a SE amp driver in triode mode, with proper stoppers and layout.

I have purchased thiese E810F years ago, when I don't know about these special valves, and at ~~USD3 each, in Brazil (only because is not a NOS 12AX7 ). Great bargain

). Great bargain

A colleague of mine promised to lend me a microscope this weekend to analyze this grid wire. I hope so! .

.

"Hmm, looks like those E810F are around $30. Ouch"

At least this E810F sample are a defective one

I have 2 E810F working examples; very difficult to tame oscillations, even at tracer. Is almost impossible to test in triode mode, even with plenty of stopper resistors and ferrite beads. But I have made it work in a SE amp driver in triode mode, with proper stoppers and layout.

I have purchased thiese E810F years ago, when I don't know about these special valves, and at ~~USD3 each, in Brazil (only because is not a NOS 12AX7

A colleague of mine promised to lend me a microscope this weekend to analyze this grid wire. I hope so!

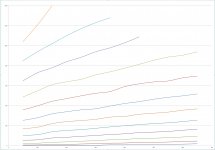

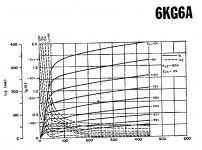

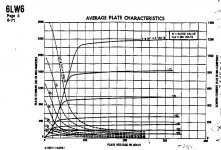

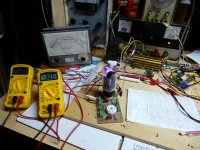

So I decided to build a big amp......and a big amp is going to need some big tubes. I drag out the biggest TV tubes that I have, wire up a test fixture and start testing tubes and even plotting a few curves, manually. This means twisting some knobs then reading the meters and writing down the numbers. That requires the tube under test to eat whatever I throw at it for long enough for the reading to settle and me to read it. Usually two to four seconds.

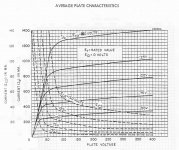

I found a rather well used tube and a totally dead one (white getters) in a batch of NOS TV tubes I bought from AES several years ago when they liquidated most of their NOS tube stock. I decided that the used one might not be trustworthy, or maybe even blow up due to gas at the levels I was planning to test, so I got out the 1 KW power supply and proceeded to plot some curves.......how's this for a TV tube. Note that I stayed away from low plate voltages (under 50) where screen dissipation becomes excessive.

Yes, this tube ate 611 watts for 2 or 3 seconds and it didn't explode.....I think I know which tube I am going to use in my amp.

I found a rather well used tube and a totally dead one (white getters) in a batch of NOS TV tubes I bought from AES several years ago when they liquidated most of their NOS tube stock. I decided that the used one might not be trustworthy, or maybe even blow up due to gas at the levels I was planning to test, so I got out the 1 KW power supply and proceeded to plot some curves.......how's this for a TV tube. Note that I stayed away from low plate voltages (under 50) where screen dissipation becomes excessive.

Yes, this tube ate 611 watts for 2 or 3 seconds and it didn't explode.....I think I know which tube I am going to use in my amp.

Attachments

is that the 6lw6? ......Maybe it's a **LR6.

Smoking - Amp.....where did you find published curves for the 6LW6. In years of searching I have found nothing, not even basic specs. Please post, or email me whatever you have on the 'LW6.

The tube in question is a 36LW6. I don't have enough good 6LW6 to build an amp. I have 30+ 35LR6 and 36LW6 so it's down to one of those two. The picture shows 3 tubes. The left one is obviously dead. The middle one is the TUT in this graph. The tube on the right has been renamed.....it is now lightning in a bottle!

So far all of my sweep tube work has been done with 150 volts on the screen. I see that the published curves for the 6LW6 sued 250 volts. Maybe further testing is needed.

I'm looking at building a 1KW tube amp. I have seen 4 X 35LR6 crank out 525 watts in Pete's Big Red Board several years ago so I know that they are capable, but my 35LR6 collection is suspect since I have already found, and tossed several poorly made tubes......loose parts inside, like the whole plate structure! Either way I will test every tube under "extreme conditions" before they see use since some expensive OPT's will be at stake and the B+ will be 650 to 700 volts.

.Those wiggles in the plate curves must be from gravitational radiation

I plotted these curves manually. The Tube Under Test was held in cutoff while all voltages were adjusted, then the test button was pushed, and I read the meters. The plate current would jump up to a steady value, then start dropping. This happens at low, high, or extreme current values, so I doubt the tube. The wiggles come from the variation in the time it took for me to read the meters.

These results were from the second test setup. The first setup had a rather quick upward current creep, which I realized came from grid current, caused by the high valued resistors in my bias circuit. The grid voltage went down with time. The second circuit has low value grid resistors, but they got rather warm, which may have caused some value change. I will figure this out before testing any more tubes.

Attachments

Last edited:

anything in the 6bx6/ef80?

This tube features a conventional control grid. There's a frame grid succedessor, though, the EF184/6EJ7 - same pinout, shorter envelope, much higher gm, lower noise figures. Both the EF80 and the EF184 were designed for IF strips in European TV sets. Their remote cutoff pendants are EF85/6BY7 and EF183/6EH7, respectively.

Best regards!

"Smoking - Amp.....where did you find published curves for the 6LW6. In years of searching I have found nothing, not even basic specs. Please post, or email me whatever you have on the 'LW6. "

The Tube Collectors Association (TCA) has a DVD set with the EIA registration of every tube. This generally includes the standard datasheet and sometimes some interesting notes about it. (even other manufacturer's comments occasionally) Like what went into the 6KN6 after the double version got dropped. (a 6KD6) It's only $50 and well worth it. All those tubes you can't find online (like 35LR6, 6LW6...) are in there. Some copyright issues, so I can't just post them publicly. (Just enough to get some interest to buy it.) (check mail ) I highly recommend their CD set, nevertheless, and it shows which manufacturer registered each tube or tube version, and when, along with updates.

TCA Notices & Announcements

However, the M2057 tube IS posted online at Franks (a somewhat grainy copy). This is the same datasheet as the 6LW6 except for basing and some variation in grid capacitance. This was a custom HF 6LW6 for Ham radio linear amps. Most online sources seem to think M2057 was a 6LX6 clone, but without a 6LW6 datasheet on the planet to compare it with, no way to check until now. Identical to 6LW6. The GE handbook has a one liner 6LW6 too.

http://tubedata.milbert.com/sheets/084/m/M2057.pdf

The TCA 6LW6 copy is nice and clean BTW. The Sylvania 35LR6 is in there too. (note: the 35LR6 grid 2 curve set seems to have 160V on the screen grid for the curve labeled 150V, a Sylvania goof, not the 1st time I've seen this on official datasheets )

Those 2.5 Ampere curves on the 6LW6 sheet are most certainly PULSED I think. Wouldn't want someone creating a black hole on the planet! eh, George...

Don

The Tube Collectors Association (TCA) has a DVD set with the EIA registration of every tube. This generally includes the standard datasheet and sometimes some interesting notes about it. (even other manufacturer's comments occasionally) Like what went into the 6KN6 after the double version got dropped. (a 6KD6) It's only $50 and well worth it. All those tubes you can't find online (like 35LR6, 6LW6...) are in there. Some copyright issues, so I can't just post them publicly. (Just enough to get some interest to buy it.) (check mail ) I highly recommend their CD set, nevertheless, and it shows which manufacturer registered each tube or tube version, and when, along with updates.

TCA Notices & Announcements

However, the M2057 tube IS posted online at Franks (a somewhat grainy copy). This is the same datasheet as the 6LW6 except for basing and some variation in grid capacitance. This was a custom HF 6LW6 for Ham radio linear amps. Most online sources seem to think M2057 was a 6LX6 clone, but without a 6LW6 datasheet on the planet to compare it with, no way to check until now. Identical to 6LW6. The GE handbook has a one liner 6LW6 too.

http://tubedata.milbert.com/sheets/084/m/M2057.pdf

The TCA 6LW6 copy is nice and clean BTW. The Sylvania 35LR6 is in there too. (note: the 35LR6 grid 2 curve set seems to have 160V on the screen grid for the curve labeled 150V, a Sylvania goof, not the 1st time I've seen this on official datasheets )

Those 2.5 Ampere curves on the 6LW6 sheet are most certainly PULSED I think. Wouldn't want someone creating a black hole on the planet! eh, George...

Don

- Home

- Amplifiers

- Tubes / Valves

- Those Magnificent Television Tubes