My buddy Bennett, the North American Sales & Operations Manager for B&C loudspeakers wrote this piece about damping factor, which I agree is quite important for tight bass reproduction:

http://bennettprescott.com/downloads/dampingfactor.pdf

Thanks for the link, I read something similar in the past, hence my comments on DF not being that important. I didn't remember the details, the conclusion was all that stuck in my mind.

This paper makes it very clear that for properly designed systems (including wire length and gauge) the damping factor of the amp is trivial at best. This is the point I was trying to make, the paper does a much better job than I did.

Hi Y'all,

Just for the reference shelfs I'm attaching a link to an article by Floyd E. Toole from 1975 on "Damping Factor". My own opinion is that it is important to reduce the distance between amplifier and driver:

http://www.northreadingeng.com/step_atten/Damping-Damping-Factor-and-Damn-Nonsense-Floyd-Toole.pdf

Entropy455 talked about using multiple drivers in Post #1, that's why I linked to Realhorns in post #21 (not the wood). Just a question, would using djk's PPSL arrangement for multiple drivers be something to consider for a full size horn? Or would the reduction in 2nd harmonic distortion be too much?

To get the best build quality, maybe glass fiber reinforced concrete (GFRC) with additives could substantially reduce wall thickness? Here is a link to one of Trinic's youtube videos:

https://www.youtube.com/watch?v=uWrV23QwtJ4

Regards,

Just for the reference shelfs I'm attaching a link to an article by Floyd E. Toole from 1975 on "Damping Factor". My own opinion is that it is important to reduce the distance between amplifier and driver:

http://www.northreadingeng.com/step_atten/Damping-Damping-Factor-and-Damn-Nonsense-Floyd-Toole.pdf

Entropy455 talked about using multiple drivers in Post #1, that's why I linked to Realhorns in post #21 (not the wood). Just a question, would using djk's PPSL arrangement for multiple drivers be something to consider for a full size horn? Or would the reduction in 2nd harmonic distortion be too much?

To get the best build quality, maybe glass fiber reinforced concrete (GFRC) with additives could substantially reduce wall thickness? Here is a link to one of Trinic's youtube videos:

https://www.youtube.com/watch?v=uWrV23QwtJ4

Regards,

Last edited:

Hi Y'all,

Just for the reference shelfs I'm attaching a link to an article by Floyd E. Toole from 1975 on "Damping Factor". My own opinion is that it is important to reduce the distance between amplifier and driver:

http://www.northreadingeng.com/step_atten/Damping-Damping-Factor-and-Damn-Nonsense-Floyd-Toole.pdf

Thanks for that paper, it's even more damning than the last one, calling DF "damn nonsense" in the title and having several quotable statements. The one I like most is this one -

"... tight, incisive, well damped sound is the result of good speaker design ..."

This is what I keep saying over and over, usually in response to Ben's posts, but it applies here as well.

Entropy455 talked about using multiple drivers in Post #1, that's why I linked to Realhorns in post #21 (not the wood). Just a question, would using djk's PPSL arrangement for multiple drivers be something to consider for a full size horn? Or would the reduction in 2nd harmonic distortion be too much?

Personal preference with respect to reduction in even order harmonic distortion is clearly subjective. DJK clearly likes it a lot while weltersys has commented that it sounded weird when he tried it. Taking away all the pleasant even order distortion and leaving the obnoxious odd order distortion seems like a bad idea. If you could take away all the odd order distortion and leave the even order distortion, that would be extremely beneficial. As it stands though, I'm not even interested in trying it.

Usually the PPSL slot is just wasted space that produces an unwanted resonance (other than the dubious benefit of eliminating a lot of even order distortion). In this case though, the space in front of the drivers is necessary as it's part of the horn path so it wouldn't be wasted, And trying it out would only require flipping half the drivers around, so there's really no downside to experimenting.

1)Regardless of the design used, if damping factor at the speaker is not adequate, it will sound "sloppy". This was clearly evident to our engineers when we would fly our speakers, the difference in "sound" between a 2 ohm load using 125' of AGW10 compared to the usual 25' was quite evident. The additional "slop" of the under-damped drivers seemed even worse since we usually ground stacked outdoors with short cord, but the long fly cable was typically used in arena "boom-boom rooms", where it is difficult to get a "tight" bass regardless of DF. Had I been more "tech savvy" regarding DF we would have gone to a bridged mono arrangement and run our quad 15" woofers in series parallel as an 8 ohm load (as I found dB Sound did later) with a 4 ohm pair bridged mono.1)Thanks for that paper, it's even more damning than the last one, calling DF "damn nonsense" in the title and having several quotable statements. The one I like most is this one -

"... tight, incisive, well damped sound is the result of good speaker design ..."

2)Personal preference with respect to reduction in even order harmonic distortion is clearly subjective. DJK clearly likes it a lot while weltersys has commented that it sounded weird when he tried it. Taking away all the pleasant even order distortion and leaving the obnoxious odd order distortion seems like a bad idea.

3) If you could take away all the odd order distortion and leave the even order distortion, that would be extremely beneficial.

4)Usually the PPSL slot is just wasted space that produces an unwanted resonance (other than the dubious benefit of eliminating a lot of even order distortion). In this case though, the space in front of the drivers is necessary as it's part of the horn path so it wouldn't be wasted, And trying it out would only require flipping half the drivers around, so there's really no downside to experimenting.

Harry Witz of dB Sound conducted A/B experiments with their MTL cabinets, and with the length of cable they used, as much as 175' for hangs in some of the tall arenas, the increased "punch" given by increasing the damping factor going from a 2 ohm load to a pair of 8 ohm loads bridged mono on the same wire made it appear that the woofers had gained between 3yo 6 dB more "level", even though by power or SPL readings they would be virtually the same.

2) When DJK first used PPSL, the speakers he used had gross amounts of even order distortion due to their very non-linear compliance, so the reduction was a benefit. When using well-designed drivers already low in even order distortion, further reduction exposes the odd-order distortion, which may sound "odd" for many musical compositions, as new notes and chords are introduced by odd order distortion, which normally would be masked by the musically benign octaves added by even order distortion. That said, when run below Xmax, well designed speakers have low enough distortion that I couldn't tell the difference between PP or "normal" driver arrangement.

3) Good speaker design using shorting rings can reduce all orders of distortion, at added cost, and reduced sensitivity.

4) Depending on the horn design, a multiple entry offset horn throat may not have enough room to be able to flip drivers around. Using a horn "stub" at the horn throat apex, as done in several of DSL's tapped horns does allow for PP mounting, though Tom has expressed that the arrangement was not used for the "benefit" of reduced even order harmonics, but for the loading advantage afforded.

Art

Last edited:

If you are referring to the information contained in Don Keele's 1973 "Optimum Horn Mouth Size" paper, then you need to be aware that conclusion he reached is not correct.

I was in fact referring to the optimum horn mouth size paper. I am very discouraged by this. Why didn’t Mr. Keele issue a retraction? I am also very frustrated in myself - in that I’m having such a hard time grasping the physics behind this full-space/half-space concept. At this point, I need to experience it for myself. I am going to build two identical 150-hz horns (simple plywood construction – nothing fancy) – however one with a full-space mouth, and one with a half-space mouth.

Test 1: I’ll hoist both horns 26 feet into the air (that’s as high as my excavator will go), and I’ll energize them with music one at a time (assume an active bandpass of 150-Hz to 1000-Hz). What should I expect to hear? Will both horns sound the same, or will one sound funny?

Test 2: I will leave the full-space horn 26 feet in the air, and I’ll set the half-space horn on the ground. What should I expect to hear now? Will they both sound identical? Note: my driveway is well compacted crushed basalt rock, sized 5/8”-minus –which is probably very acoustically similar to asphalt pavement.

Test 3: I will set both horns on the ground. What should I expect to hear? For test 3, the full-space horn mouth is theoretically twice what’s required. Question: is this a bad thing? I.E. are there negative implications for using a full-space horn, adjacent to a planar surface? Are there any benefits? Will the horns sound the same, or different???

Floyd E. Toole from 1975 on "Damping Factor"

Apparently Mr. Keele was wrong in his paper, is it possible that Mr. Toole was wrong in is paper also?

Justification/Reason: The owner’s manual for my Crown MT-5000VZ amplifier states that a pair of 8 gauge wires, 10 feet in length, into an 8-Ohm load, will yield a system damping factor of 500. The same amplifier, into the same 8-Ohm load, with 50 feet of 20 gauge wire, will return a system damping factor of 10. I can assure you (as sure as I am that the Sun will rise tomorrow), that you will absolutely hear a pronounced difference in sound quality between the two – all else being equal. I’ve been to high-end stereo stores. I’ve seen the 25,000 dollar speaker wire that’s the size of a garden hose, that’s hooked up to the 140,000 dollar Class-A Master-Reference amplifiers. They claim the garden-hose speaker wire is to near-perfectly balance the lead’s impedance across the full audio spectrum, and also to provide fantastically low DCR between your amp and speakers. Is it all snake oil? I really don’t think so. . . .

I’m a Pepsi Challenge type of guy. I normally won’t write off a product, until after I’ve made my own evaluation. I’ve owned a lot of amplifies over the past 25 years, many different brands, many different types. I’ve still got a pair of giant magnetic resonance imagery (MRI) mono bock amplifies – used to drive the MRI’s magnetic field windings. (These particular amps came out of Children’s Hospital in Columbus Ohio). They were manufactured by Crown Industrial (not their audio division). They weigh about 100 pounds each, and on a 240 volt line, pack a very serious punch into an audio load! But I digress. . ..

Currently the only amplifiers I own are Crown – I’ve sold everything else. Does that mean Crown is the best? Absolutely not - it simply means they’re the best I’ve owned. I’m sure there are much better amps to be had. Again, Krell Master-Reference amplifiers come to mind. . . .

But what the heck – at 400 bucks, I might just have to take the Pepsi Challenge and purchase a Berhringer NU4-6000 - put it up against one of my MT-3600VZ amps, and see how it sounds? I can always sell it, if I don’t like how it sounds. . . .

Last edited:

1)Regardless of the design used, if damping factor at the speaker is not adequate, it will sound "sloppy". This was clearly evident to our engineers when we would fly our speakers, the difference in "sound" between a 2 ohm load using 125' of AGW10 compared to the usual 25' was quite evident. The additional "slop" of the under-damped drivers seemed even worse since we usually ground stacked outdoors with short cord, but the long fly cable was typically used in arena "boom-boom rooms", where it is difficult to get a "tight" bass regardless of DF. Had I been more "tech savvy" regarding DF we would have gone to a bridged mono arrangement and run our quad 15" woofers in series parallel as an 8 ohm load (as I found dB Sound did later) with a 4 ohm pair bridged mono.

No arguments here - proper design is proper design. If designed improperly damping factor can be an issue - and not the only issue.

Harry Witz of dB Sound conducted A/B experiments with their MTL cabinets, and with the length of cable they used, as much as 175' for hangs in some of the tall arenas, the increased "punch" given by increasing the damping factor going from a 2 ohm load to a pair of 8 ohm loads bridged mono on the same wire made it appear that the woofers had gained between 3yo 6 dB more "level", even though by power or SPL readings they would be virtually the same.

2) When DJK first used PPSL, the speakers he used had gross amounts of even order distortion due to their very non-linear compliance, so the reduction was a benefit. When using well-designed drivers already low in even order distortion, further reduction exposes the odd-order distortion, which may sound "odd" for many musical compositions, as new notes and chords are introduced by odd order distortion, which normally would be masked by the musically benign octaves added by even order distortion. That said, when run below Xmax, well designed speakers have low enough distortion that I couldn't tell the difference between PP or "normal" driver arrangement.

3) Good speaker design using shorting rings can reduce all orders of distortion, at added cost, and reduced sensitivity.

4) Depending on the horn design, a multiple entry offset horn throat may not have enough room to be able to flip drivers around. Using a horn "stub" at the horn throat apex, as done in several of DSL's tapped horns does allow for PP mounting, though Tom has expressed that the arrangement was not used for the "benefit" of reduced even order harmonics, but for the loading advantage afforded.

Art

Good notes all around.

I was in fact referring to the optimum horn mouth size paper. I am very discouraged by this. Why didn’t Mr. Keele issue a retraction?

Who knows? Doesn't matter. Maybe he did.

I am also very frustrated in myself - in that I’m having such a hard time grasping the physics behind this full-space/half-space concept. At this point, I need to experience it for myself. I am going to build two identical 150-hz horns (simple plywood construction – nothing fancy) – however one with a full-space mouth, and one with a half-space mouth.

First of all, if the mouth size is different then by definition they are not identical. If they have the same flare and one has a mouth 2x larger the whole horn will be 2x larger.

Anyway, this is hardly required.

A much more simple test would be to take any small sub (let's say an 8 inch sub in a small sealed box) and put it up in the air. And MEASURE it. Then put in on the ground and MEASURE it. There will be a very significant difference.

If you want to see the effects of diffraction (boundary reflection) in action in a sim (which is a whole lot easier than any experiment and just as valid) just download a diffraction simultator. A couple of good ones are "The Edge" and Bagby's "Diffraction and Boundary Simulator".

I recommend the second, as it shows diffraction effects of a baffle AND from nearby reflective surfaces. It assumes infinitely rigid baffles and boundaries, but you can clearly see that the effect is like a mirror - perfect reinforcement based on boundary loading (which is relative to size, distance and frequency) in addition to notches in response related to sound source distance to boundary.

Like I said, these simple sims are just as relevant as physical experiments and take a lot less time and effort. And sims WILL match measurements if you do an accurate sim and measure what you simulated accurately.

Bagby's spreadsheet is here - Loudspeaker Design Software

Boundary loading, reflections, these are very basic fundamentals of audio theory. You literally cannot competently design a speaker if you don't understand how this stuff works.

Will the horns sound the same, or different???

Your proposed experiment is flawed in several ways. First, you need to measure. Forget trying to critically listen to a horn 26 feet in the air and then a different horn on the ground. It's impossible to judge this by ear for several reasons, not the least of which is that auditory memory is very fickle and fleeting. A mic will be a much better judge.

Apparently Mr. Keele was wrong in his paper, is it possible that Mr. Toole was wrong in is paper also?

Not likely. Lots of people have performed these damping factor exercises and experiments, including weltersys. They all agree - except the reports from people that don't really know what they are doing.

I can assure you (as sure as I am that the Sun will rise tomorrow), that you will absolutely hear a pronounced difference in sound quality between the two – all else being equal.

I can assure you that all else is not equal. Different amps can sound different for different reasons. And as I mentioned, auditory memory and perception is fickle and unreliable. The eyes are a much stronger influence than anything you hear. If you don't do blind testing the conclusions are not valid. This might sound stupid but it's been proven scientifically over and over beyond any doubt.

Last edited:

Seems that the folks arguing about DF don't know basic horn theory (or maybe basic amp theory too).

As Toole showed, at its best with gawd-dawful tuned boxes at some frequencies and wire lengths and voice coil resistances, low output impedance can be a small but welcome benefit. Shorting the voice coil with a low output impedance is more helpful when you have a lousy design.*

With horns, as previous posters don't seem to know, air loading gets closer to matching the monstrously heavy cone and that appropriately supplants the electrical damping, particularly for the near-ideal horn OP is contemplating.

Electric damping is a kind of beneficial negative (degenerative) motional feedback. Like active MF, it does sort of get compared to the input signal as far as I understand it, but obviously has no gain factor.

Ben

*all Rice-Kellogg drivers are a lousy design

B.

As Toole showed, at its best with gawd-dawful tuned boxes at some frequencies and wire lengths and voice coil resistances, low output impedance can be a small but welcome benefit. Shorting the voice coil with a low output impedance is more helpful when you have a lousy design.*

With horns, as previous posters don't seem to know, air loading gets closer to matching the monstrously heavy cone and that appropriately supplants the electrical damping, particularly for the near-ideal horn OP is contemplating.

Electric damping is a kind of beneficial negative (degenerative) motional feedback. Like active MF, it does sort of get compared to the input signal as far as I understand it, but obviously has no gain factor.

Ben

*all Rice-Kellogg drivers are a lousy design

B.

Last edited:

Seems that the folks arguing about DF don't know basic horn theory (or maybe basic amp theory too).

Ben

*all Rice-Kellogg drivers are a lousy design

B.

This nonsense is an amusing but ultimately futile diversion from reality.

Please show us a motional feedback 20 hz esl horn or stop with the rambling. This is not going to be derailed into another rant on the problems with resonances, moving coil drivers and lack of motional feedback. Take the hint - you are being ignored here, as you have no concept of how horns work and a tenuous grasp on basic theory.

Just some thoughts.

Hi Entropy455,

Your are describing a very intensive set of experiments in Post #46; I'd just go w/ David McBeans advice from Post #37:

"...When radiating into 4 Pi space, making the mouth circumference equal to the cutoff frequency wavelength gives an acceptable performance, and from a practical viewpoint is a reasonable "rule of thumb" to use. If radiating into 2 Pi half space, that mouth area can be halved...Second harmonic distortion primarily depends on the flaring rate close to the horn throat, not on the mouth area. Most of the distortion occurs near the throat. For minimum distortion the cutoff frequency should be as large as possible."

As to PPSL: if you are performing tests it would be relatively easy to design the throat to allow for a driver mounting stub(s) as Art points out in Post #45. djk has talked about the reduction not only in 2nd harmonic distortion, but also about higher orders, as well as FMD (frequency modulation distortion / doppler). Epa has tried to compare PPSL mounting v. regular PP mounting in a dual 15" tapped horn, http://www.diyaudio.com/forums/subwoofers/231339-double-15-th-18-sound-15-nlw9401-4r.html with mixed results. It would be great to get some data for PPSL applied to a full size bass horn, even if it is subjective. -

Regards,

Hi Entropy455,

Your are describing a very intensive set of experiments in Post #46; I'd just go w/ David McBeans advice from Post #37:

"...When radiating into 4 Pi space, making the mouth circumference equal to the cutoff frequency wavelength gives an acceptable performance, and from a practical viewpoint is a reasonable "rule of thumb" to use. If radiating into 2 Pi half space, that mouth area can be halved...Second harmonic distortion primarily depends on the flaring rate close to the horn throat, not on the mouth area. Most of the distortion occurs near the throat. For minimum distortion the cutoff frequency should be as large as possible."

As to PPSL: if you are performing tests it would be relatively easy to design the throat to allow for a driver mounting stub(s) as Art points out in Post #45. djk has talked about the reduction not only in 2nd harmonic distortion, but also about higher orders, as well as FMD (frequency modulation distortion / doppler). Epa has tried to compare PPSL mounting v. regular PP mounting in a dual 15" tapped horn, http://www.diyaudio.com/forums/subwoofers/231339-double-15-th-18-sound-15-nlw9401-4r.html with mixed results. It would be great to get some data for PPSL applied to a full size bass horn, even if it is subjective. -

Regards,

Info found from the link below: 6 meter long hyperbolic expansion which reaches 18 Hz equipped with 15-inch Klangfilm. Paste the URL inte google translate.

https://translate.google.com/transl...pic.asp?TOPIC_ID=51233&whichpage=1&edit-text=

//

https://translate.google.com/transl...pic.asp?TOPIC_ID=51233&whichpage=1&edit-text=

//

Ok TNT, now that is pretty darn cool. I didn’t realize what I was looking at initially. I wish I could read the text on the website - without having to copy & paste into a translator (I can only read English)

What is Bo using for drivers? What is the cutoff frequency of the horns? The third picture reminds me of looking down through some deck-grates and into the belly of a ship. I love it!

I've wondered about putting horns into the floor of a large room, and how one would keep people (and pets) from falling into the horn. The grates seem like an excellent idea. They appear to be fully welded assemblies - which I'm assuming would keep them from rattling. . . It's like a big speaker grill.. . .

Just-a-guy, you are splitting hairs for the purpose of engaging in argument. It’s painfully obvious that the test-horns I proposed building would be different overall sizes – that’s kind of the whole point. . . . Can you please specifically provide your opinion on post #23 of this thread? My end-goal is to actually build a set of horns – and not become some internet horn-simulation sensational.

And regarding the significance of damping factor, let’s just agree to disagree. However if you are hell-bent on making your point, I recommend you comb through the archives for the “best sounding amplifier” type forums.. Then lookup manufacturer's data & generate an excel spreadsheet for the damping-factors. Do this, and I’m confident that one of us will be proven absolutely wrong. . . . (and please do not include transformer-coupled tube amplifiers in your results - in an attempt to skew your findings . .. )

Lastly, your condescending tone towards bentoronto reflects poorly upon yourself. I personally would not like to see Ben shut out of this discussion, simply because you happen to disagree with what he’s got to say. . . .

TB46, I am still greatly conflicted by the statement “If radiating into 2 Pi half space, that mouth area can be halved...” There is a big difference between “can” be halved, and “should” be halved. The advantages to a smaller horn mouth seem obvious – less size, less length, less material, less cost, etc. However, what exactly is being compromised when I cut the mouth of my bass horn in half??? Fidelity, efficiency, degraded impedance miss-match –i.e. is there any negative impact whatsoever in cutting my horn’s mouth area in half? I hate beating a dead horse, but this implies like I can cut the bell of a Tuba in half, stand along a wall, and have the Tuba sound just as good as the un-cut original? And that I may cut the bell in half again, stand in the corner, and have it sound just as good as the uncut original, yet again. . .. For the life of me, I just can’t picture that working.. . .

Please understand, I am only going to build a set of outdoor concrete bass horns one time. . . . If I cast mistakes into my horns, there will be no second attempt (well, there “probably” won’t be a second attempt. . . never say never)

And regarding the significance of damping factor, let’s just agree to disagree. However if you are hell-bent on making your point, I recommend you comb through the archives for the “best sounding amplifier” type forums.. Then lookup manufacturer's data & generate an excel spreadsheet for the damping-factors. Do this, and I’m confident that one of us will be proven absolutely wrong. . . . (and please do not include transformer-coupled tube amplifiers in your results - in an attempt to skew your findings . .. )

Lastly, your condescending tone towards bentoronto reflects poorly upon yourself. I personally would not like to see Ben shut out of this discussion, simply because you happen to disagree with what he’s got to say. . . .

TB46, I am still greatly conflicted by the statement “If radiating into 2 Pi half space, that mouth area can be halved...” There is a big difference between “can” be halved, and “should” be halved. The advantages to a smaller horn mouth seem obvious – less size, less length, less material, less cost, etc. However, what exactly is being compromised when I cut the mouth of my bass horn in half??? Fidelity, efficiency, degraded impedance miss-match –i.e. is there any negative impact whatsoever in cutting my horn’s mouth area in half? I hate beating a dead horse, but this implies like I can cut the bell of a Tuba in half, stand along a wall, and have the Tuba sound just as good as the un-cut original? And that I may cut the bell in half again, stand in the corner, and have it sound just as good as the uncut original, yet again. . .. For the life of me, I just can’t picture that working.. . .

Please understand, I am only going to build a set of outdoor concrete bass horns one time. . . . If I cast mistakes into my horns, there will be no second attempt (well, there “probably” won’t be a second attempt. . . never say never)

Just-a-guy, you are splitting hairs for the purpose of engaging in argument. It’s painfully obvious that the test-horns I proposed building would be different overall sizes – that’s kind of the whole point. . . . Can you please specifically provide your opinion on post #23 of this thread? My end-goal is to actually build a set of horns – and not become some internet horn-simulation sensational.

Hardly. This is basic theory, not splitting hairs. And it's not an argument, I told you to get Bagby's simulator and try it out. If you see this as an unhelpful argument I'm not going to be able to convince you otherwise, but you can trust that accurate sims match measurements, and that spreadsheet will show you what's up with boundary reflections. If you want to go to the trouble of an extremely elaborate flawed experiment instead, that's fine.

And regarding the significance of damping factor, let’s just agree to disagree. However if you are hell-bent on making your point, I recommend you comb through the archives for the “best sounding amplifier” type forums.. Then lookup manufacturer's data & generate an excel spreadsheet for the damping-factors. Do this, and I’m confident that one of us will be proven absolutely wrong. . . . (and please do not include transformer-coupled tube amplifiers in your results - in an attempt to skew your findings . ..

It sounds like you are trying to convince me to go to "audiophile" type forums and tally their subjective opinions. No thanks. I'll take science for the win, Alex.

Besides, this hardly matters. Use whatever amp you want. I just pointed out that the science says amp damping factor doesn't matter in PROPERLY designed systems, several people have agreed and supplied papers from notable respectable authorities. If you don't agree that's fine. Use whatever amp you want. I couldn't really care less, amps are amps.

Lastly, your condescending tone towards bentoronto reflects poorly upon yourself. I personally would not like to see Ben shut out of this discussion, simply because you happen to disagree with what he’s got to say. . . .

I've been dealing with Ben for at least a couple of years now. Everyone disagrees with what he's got to say. I've never seen a forum more polarized against the viewpoints of a single individual - well maybe once or twice, but only in the case of dedicated trolls only intent on disrupting the status quo.

If you want your thread turned into a long rant on the deficiencies of simulators, the idiocy of the people that use them, the evils of resonance and the absolute need for motional feedback, that's fine with me too. Those are his main dogma points, and they are completely contrary to what you want to achieve, point for point.

It would seem at this point that you've come here to try to get your preconceived notions confirmed. I'm sorry that it's not going the way you would have liked. You have been wrong about just about everything so far - 18 inch drivers and the "speed" issue, the importance of damping factor, how a horn should be designed, how it should be simulated after it's designed, the effect of mouth size on distortion, and that's just off the top of my head. So did you come here to actually learn something or to push ahead with what you were going to do anyway?

Thanks. As you can see, like a number of others posting and lurking, we are thrilled to see you carry out your plan. Good luck.Lastly, your condescending tone towards bentoronto reflects poorly upon yourself. I personally would not like to see Ben shut out of this discussion, simply because you happen to disagree with what he’s got to say. . . .

With a cone driver, there is no theoretically correct way to make music except by horn impedance matching. Too bad the construction is so daunting. While an infinite baffle comes closest to making sense, still not a good solution.

Of course, the drivers available "on the shelf" are not designed for driving a horn. Lowther??? Maybe your dream would be better propelled if you could find (or re-construct) a driver that is right and produce a horn with that as a starting point.

BTW, now and then somebody asks about mating electrostatics with horns. Most of those replying view it as a solution to something that isn't a problem. But an intellectually interesting notion.

Again, good luck.

Ben

Last edited:

You have been wrong about just about everything so far - 18 inch drivers and the "speed" issue, the importance of damping factor, how a horn should be designed, how it should be simulated after it's designed, the effect of mouth size on distortion, and that's just off the top of my head. So did you come here to actually learn something or to push ahead with what you were going to do anyway?

Wow – you guys are a tough crowd. . . .

I didn’t know that Don Keele's 1973 paper on Optimum Horn Mouth Size was essentially garbage. And I did say that 18s sounded like 18s, and that I believe the damping factor is one of the most important amplifier parameters. Nonetheless, I do not recall ever claiming to know how a horn should be designed and/or simulated. Believe me if I knew what I was doing, I’d be out back building my horns, and not asking you guys what probably seems like trivial conceptual design questions.

Bentoronto (and anyone else who may be quietly lurking) if I could please trouble you with two pointed questions:

1) Assume for the moment that you are getting paid (well paid) to completely design these horns for me (i.e. a hypothetical contract, in which you’d be tasked to completely design some quality outdoor full-size 20-Hz concrete bass horns). Question: before you even open a simulator, where would your years of experience guide you to begin? I.E. would you lean towards installing eight (or even more) 18” drivers into a massive throat as just-a-guy recommended? Or would you lean towards running a more traditional single 12” driver, or perhaps a single 15” driver, or even a few 12s - within a smaller throat? Where would your design experience take you?

2) The majority of references I’ve found on the subject of horn design date back to the early 70s - where high BL, low Qts, and low MMS drivers were identified as ideal. I am starting to believe (from the responses I received from the two threads that I’ve started on these boards) that the advent of modern drivers, together with advent of modern high power amplifiers, have essentially rendered many of these early horn design engineering references obsolete (or at least rendered many of their conclusions obsolete). Thus can you please recommend a more recent & comprehensive engineering text on the subject of bass horn design?

Thank you. Your opinion is much appreciated!

I told you to get Bagby's simulator and try it out. If you see this as an unhelpful argument I'm not going to be able to convince you otherwise

I downloaded Jeff Bagby’s Baffle Diffraction and Boundary Simulator (version 1.20), as you've recommended. Unfortunately I cannot get the program to operate on my computer. I have Windows 10, and 2010 Excel. It doesn't seem to work on my machine.

Last edited:

Of course, the drivers available "on the shelf" are not designed for driving a horn. Lowther??? Maybe your dream would be better propelled if you could find (or re-construct) a driver that is right and produce a horn with that as a starting point.

I’m assuming the lack of proper off-the-shelf horn drivers would imply there’s not a large enough market to justify their manufacturing costs.

I’ve daydreamed about purchasing a large 21” driver with 6” voice coil, robbing the motor-structure, and using it to build a true “compression horn” bass driver. However I’d never really considered that as being a reality, nor as being the starting point for an actual horn project - nor do I know if it would actually work. I do have a lathe and a mill though. . ..

And on the subject of off-the-shelf - I like to shop for drivers (like a woman in a shoe store). One thing I’ve noticed when shopping for 12” accordion-surround drivers, is the application/description assigned to each driver (when provided by the OEM). Some will say excellent for mid-bass applications, some will say excellent for vented enclosures, some will say excellent for sealed enclosures, and bla-bla-bla. But what’s really caught my eye, is whenever the driver is advertised as being excellent for horn-loaded applications - the BL will be high, the Qts will be low, the MMS will be low, and the Xmas will be high. This is in accordance with the old 1970 engineering references on the subject of horn design. Question: is it possible that these drivers, while not "ideal" for horn loading, are the best suited off-the-shelf drivers for horn-loaded applications? Or is this just false-advertising on behalf of the speaker manufacturers?

Last edited:

However, what exactly is being compromised when I cut the mouth of my bass horn in half???

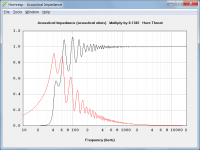

If the horn flare rate and throat area are held constant and the mouth area is reduced by shortening the horn axial length, the ripples in the throat acoustical impedance will become larger, and further apart, as shown in the attached examples (2 Pi radiation assumed in each case).

Attachment 1:

S1 =300

S2 =50000

L12 (Exp) = 360

F12 = 38.90 Hz

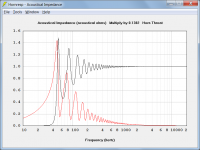

Attachment 2:

S1 =300

S2 =25000

L12 (Exp) = 311.24

F12 = 38.90 Hz

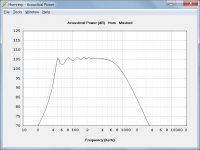

Attachment 3 compares the power responses of the two horns - the black trace shows the response with the mouth area halved.

There is nothing special about a horn that has a mouth circumference equal to one cutoff frequency wavelength, it is just a convenient arbitrary value to use. For a given flare rate and throat size, the larger the mouth the smoother the overall response. Cir = 1 is often used in horn design simply because it is a reasonable compromise between size and performance. It could perhaps be considered an "optimum" value for that reason, but not for the reason given by Don Keele.

Attachments

Last edited:

1) Assume for the moment that you are getting paid (well paid) to completely design these horns for me (i.e. a hypothetical contract, in which you’d be tasked to completely design some quality outdoor full-size 20-Hz concrete bass horns). Question: before you even open a simulator, where would your years of experience guide you to begin? I.E. would you lean towards installing eight (or even more) 18” drivers into a massive throat as just-a-guy recommended? Or would you lean towards running a more traditional single 12” driver, or perhaps a single 15” driver, or even a few 12s - within a smaller throat? Where would your design experience take you?

I know you specifically don't want my input on this, but to clear up my earlier input - the amount of drivers used is completely up to you. You can use a single 12 if you want. That just seems weird to me to attach a single $200 driver to a $20000 horn. And since I would always build modular units, each modular unit needs it's own driver. In the past I've simulated a 22 hz horn with 24 drivers - that makes each modular unit about the size of a labhorn. But to be clear, you can use a single 12 inch driver if you want - but then your horn can be easily outperformed by a much smaller and cheaper horn.

2) The majority of references I’ve found on the subject of horn design date back to the early 70s - where high BL, low Qts, and low MMS drivers were identified as ideal. I am starting to believe (from the responses I received from the two threads that I’ve started on these boards) that the advent of modern drivers, together with advent of modern high power amplifiers, have essentially rendered many of these early horn design engineering references obsolete (or at least rendered many of their conclusions obsolete). Thus can you please recommend a more recent & comprehensive engineering text on the subject of bass horn design?

Thank you. Your opinion is much appreciated!

The math and physics have never changed. "On the specification of moving coil drivers for low frequency horns" by Leach is widely regarded as the best horn model. It's going to be tough to beat Leach's model.

Leach doesn't give driver or parameter recommendations - he lets the math do that.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question