Regarding LS3/5a responses, it's also notable that the original prototypes used the 9mm thin wall cabinets not 12mm assumed in all subsequent production. The 12mm is described in theBBC paper, if memory serves wright (it mayn't do).

I had also read that somewhere, I also belive the prototypes had removable front and rear pannels where as the production model and it's rear pannel glued in place.

Would this alter the way the speaker sounded, I don't know?

If you look on the Harbeth site there is a lot of info about why they make cabinets with removable front and rear panels. It mostly centres on decoupling as much surface area from each other as possible. Not as easy to manufacture, though.

Stirling make two grades of LS3 cabinet. Hybrid has a glued back panel whereas Reference has the removable back. Having a removable baffle certainly makes driver mounting easier. No more horrible T-nuts!

The 9mm cabinets should work better. According to the original BBC research paper by Harwood, thicker cabinets didn't work better than thinner. The damping pads are also (as I understand it) supposed to be the same thickness as the panel.

I recently built a wide, shallow enclosure for Jordan JXR6s for wall mounting. The front panel is 300 x 250 mm and unbraced. Despite being 9mm MDF with three layers of 3mm bitumin pads in place it sounds quite dead. The pads cover 50% of the surface area as recommended in the original Harwood paper. It was my first use of the technique and I was impressed with the results.

Stirling make two grades of LS3 cabinet. Hybrid has a glued back panel whereas Reference has the removable back. Having a removable baffle certainly makes driver mounting easier. No more horrible T-nuts!

The 9mm cabinets should work better. According to the original BBC research paper by Harwood, thicker cabinets didn't work better than thinner. The damping pads are also (as I understand it) supposed to be the same thickness as the panel.

I recently built a wide, shallow enclosure for Jordan JXR6s for wall mounting. The front panel is 300 x 250 mm and unbraced. Despite being 9mm MDF with three layers of 3mm bitumin pads in place it sounds quite dead. The pads cover 50% of the surface area as recommended in the original Harwood paper. It was my first use of the technique and I was impressed with the results.

Last edited:

Would I be right in thinking that the methodoligy of the LS3 cabienet is that being small makes it more rigid requireing less bracing and using thin walls with a layer of pannel damping so as little energy as possible can be stored in the enclosure?

Would like to try this method of construction using a ScanSpeak 5F for use as a desktop speaker.

Would like to try this method of construction using a ScanSpeak 5F for use as a desktop speaker.

Last edited:

A very interesting discussion, my friends. Thin ply construction relies on low stored energy, and hence good transient response. You take your beating at very low frequencies below, say, 100Hz, then damp the rest with bitumen or rubber.

According to the BBC, the low frequency cabinet resonances are inaudible anyway. I'd suspect a removable back panel is a good thing. It will resonate in sympathy with the removable front panel, but the wave must pass the damped centre structure of side, top and bottom. Hence it is absorbed above 100Hz.

Suppose you make the sides out of massive granite. Sounds like a good idea initially, until you really think about it. The front panel vibrations then have nowhere to go. The whole front panel will resonate sharply, including the metal chassis. Not good. It sounds horrible.

Back to SS4927:

I have no gripe with paper, just that it is a less damped material than plastic and needs more filtering.

Paper dustcaps incur my ire however. The better solutions use soft rubbery or cloth dustcaps, or even no dustcap at all, like phase plugs. My moment of enlightenment came from following a physics course on string theory. High frequency waves behave badly on a sphere, as Prof. Leonard Susskind explains around 33 mins. into the lecture.

Lecture 9 | String Theory and M-Theory - YouTube

You can draw your own conclusions about dome tweeters...

According to the BBC, the low frequency cabinet resonances are inaudible anyway. I'd suspect a removable back panel is a good thing. It will resonate in sympathy with the removable front panel, but the wave must pass the damped centre structure of side, top and bottom. Hence it is absorbed above 100Hz.

Suppose you make the sides out of massive granite. Sounds like a good idea initially, until you really think about it. The front panel vibrations then have nowhere to go. The whole front panel will resonate sharply, including the metal chassis. Not good. It sounds horrible.

Back to SS4927:

I noticed that while searching for speakers, like the revelator uses sliced paper cone technology. This sounds like it counteracts the gripe he has with paper.

The sliced paper cone technology represented a breakthrough in midrange clarity and overall smooth frequency response characteristics. The slices are filled with damping glue, which dramatically reduce break-up modes in the diaphragm.

I have no gripe with paper, just that it is a less damped material than plastic and needs more filtering.

Paper dustcaps incur my ire however. The better solutions use soft rubbery or cloth dustcaps, or even no dustcap at all, like phase plugs. My moment of enlightenment came from following a physics course on string theory. High frequency waves behave badly on a sphere, as Prof. Leonard Susskind explains around 33 mins. into the lecture.

Lecture 9 | String Theory and M-Theory - YouTube

You can draw your own conclusions about dome tweeters...

Attachments

Last edited:

I am not at all sure that one can use high frequency behaviour of subatomic particles to extrapolate on audio waves through a medium or vice versa.

They behave substantially different from each other and have different, even opposing, characteristics.

For starters HF waves through a medium like air or water are of lower energy than LF while when it comes to subatomic particles the exact opposite is true.

They behave substantially different from each other and have different, even opposing, characteristics.

For starters HF waves through a medium like air or water are of lower energy than LF while when it comes to subatomic particles the exact opposite is true.

Regarding the audibility of panel vibrations, when I first built my Iron Lawbreakers, I used 19mm Baltic Birch for all but the back panel for which I substituted a cheaper grade of 9 layer plywood bought in a hardware store. This is a larger cabinet, btw, with a 29" height and fairly strongly braced internally.

Anyway, I was shocked at the negative sonic contribution of the back panel. I quickly replaced it with Baltic Birch also, upon which things quickly improved.

I would suspect that LS3/5A's versions having 9mm vs 12mm panel thickness should lead to noticeable changes in the upper LF tonality - the thinner panel may add more 'euphony' at a slightly higher frequency - the possibility exists of adding a bit too much by reducing panel thickness such that all instruments with spectral content in that band may start to sound more 'similar' than desired if there are no other discrepancies in that band such as a mild frequency response aberration that such an effect would tend to mask. I've experienced this with a Spendor speaker with 8" woofer I was once considering, thus turned it down. So, I suppose I like the sonic effects of thin wall construction, as long as there isn't much of it above the lowest few octaves.

Anyway, I was shocked at the negative sonic contribution of the back panel. I quickly replaced it with Baltic Birch also, upon which things quickly improved.

I would suspect that LS3/5A's versions having 9mm vs 12mm panel thickness should lead to noticeable changes in the upper LF tonality - the thinner panel may add more 'euphony' at a slightly higher frequency - the possibility exists of adding a bit too much by reducing panel thickness such that all instruments with spectral content in that band may start to sound more 'similar' than desired if there are no other discrepancies in that band such as a mild frequency response aberration that such an effect would tend to mask. I've experienced this with a Spendor speaker with 8" woofer I was once considering, thus turned it down. So, I suppose I like the sonic effects of thin wall construction, as long as there isn't much of it above the lowest few octaves.

Last edited:

@Charles Darwin: You need to think about it. Waves behave much better on a ring torus. So which of these two will sound better above 7kHz breakup point?

It's not rocket science to figure out that with a thick rigid braced cabinet with a thin floppy back panel, all the vibration and movement will find its way to the undamped 9mm back panel. You misunderstood what you were trying to do. Not BBC at all.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Regarding the audibility of panel vibrations, when I first built my Iron Lawbreakers, I used 19mm Baltic Birch for all but the back panel for which I substituted a cheaper grade of 9 layer plywood bought in a hardware store. This is a larger cabinet, btw, with a 29" height and fairly strongly braced internally.

Anyway, I was shocked at the negative sonic contribution of the back panel. I quickly replaced it with Baltic Birch also, upon which things quickly improved.

...snip

It's not rocket science to figure out that with a thick rigid braced cabinet with a thin floppy back panel, all the vibration and movement will find its way to the undamped 9mm back panel. You misunderstood what you were trying to do. Not BBC at all.

The following summary from Mark Wheeler - TNT UK of a number of listening tests is interesting:

Thicker walls make better defined bass, whatever the material

Damped thin-wall birch-ply makes the least midrange colouration (12mm w/bitumen)

MDF sucks the life out of the music in each type we tried

Thicker baffles retrieve more musical information at all frequencies (25mm)

Mark Wheeler's comments seem to make sense. You really have two schools of cabinet building. Heavy and light with different advantages.

For an BBC LS3/5A clone, it's gotta be light birch plywood and light beech battens though. It's all about the energy storage. http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

The BBC damped the smaller panels more. Double layer bitumen on top and bottom. Smaller cabinets are a lot easier, being structurally more rigid.

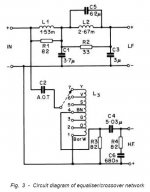

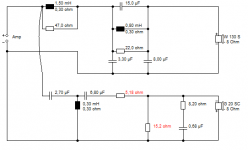

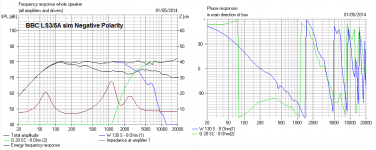

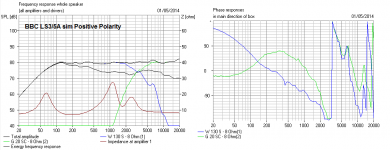

I did an analysis of the crossover elsewhere. This Visaton driver sim has all the essential features except my ugly attenuator on the treble. It would be nice to lose or redesign that, since it spoils the amp friendly rising top end impedance of the LS3/5A. The positive polarity version might be more practical.

For an BBC LS3/5A clone, it's gotta be light birch plywood and light beech battens though. It's all about the energy storage. http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

The BBC damped the smaller panels more. Double layer bitumen on top and bottom. Smaller cabinets are a lot easier, being structurally more rigid.

I did an analysis of the crossover elsewhere. This Visaton driver sim has all the essential features except my ugly attenuator on the treble. It would be nice to lose or redesign that, since it spoils the amp friendly rising top end impedance of the LS3/5A. The positive polarity version might be more practical.

Attachments

It's worth remembering that the LS3/5a was designed for a specific professional use and not aimed at the home market. The original brief was a small speaker for outside broadcast monitoring which would be good on voice - the target LF response was 400Hz!

Similarly, the Harwood paper on cabinet design is a balance of results and expense - good engineering, in other words. It found that thicker cabinet walls did not suppress bass backwaves from the loudspeaker any more than thinner. Also that the bitumin pads had to be similar thickness to the birch ply walls, so it made sense on cost and weight grounds to use thinner ply walls.

Here is the original paper

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

and here is one from a decade later which sums up the BBC's findings and approach to monitor design

http://downloads.bbc.co.uk/rd/pubs/reports/1988-14.pdf

The aim was emphatically not to produce a loudspeaker with a euphonic sound. They were after an accurate monitor for use in broadcast situations where the reference was the live performer on the other side of the gallery glass.

The first paper above actually mentions promising composite cabinet materials as an alternative to ply. The BBC no longer has an engineering research department otherwise there is no doubt that there would be newer designs capable of even better results.

Similarly, the Harwood paper on cabinet design is a balance of results and expense - good engineering, in other words. It found that thicker cabinet walls did not suppress bass backwaves from the loudspeaker any more than thinner. Also that the bitumin pads had to be similar thickness to the birch ply walls, so it made sense on cost and weight grounds to use thinner ply walls.

Here is the original paper

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

and here is one from a decade later which sums up the BBC's findings and approach to monitor design

http://downloads.bbc.co.uk/rd/pubs/reports/1988-14.pdf

The aim was emphatically not to produce a loudspeaker with a euphonic sound. They were after an accurate monitor for use in broadcast situations where the reference was the live performer on the other side of the gallery glass.

The first paper above actually mentions promising composite cabinet materials as an alternative to ply. The BBC no longer has an engineering research department otherwise there is no doubt that there would be newer designs capable of even better results.

My own interest in using a LS3/5a cabinet with the Jordan Eikona was to ensure the enclosure made as little contribution to the sound as possible, within practical limits.

I prefer sealed enclosures, leaving the bass to a pair of stereo active subs. This gives a wide range system with considerable flexibility and minimum visual impact.

I prefer sealed enclosures, leaving the bass to a pair of stereo active subs. This gives a wide range system with considerable flexibility and minimum visual impact.

Hi - It betters the Lowther and EAD drivers I've heard and rivals a high end, two way active I'm using. Eikona 2 is a very clear, detailed, natural-sounding driver.

As I mentioned earlier, I'm not using it in the best alignment by putting it in a LS3/5a cabinet. It sounds lightweight as a result. Properly loaded in a 7.5 litre reflex, I think they'd sound even better. That's my next build and based on experience with the Stirling Broadcast cabinet, I'll follow the same construction and use 9mm, bitumen damped ply with a removable baffle.

As I mentioned earlier, I'm not using it in the best alignment by putting it in a LS3/5a cabinet. It sounds lightweight as a result. Properly loaded in a 7.5 litre reflex, I think they'd sound even better. That's my next build and based on experience with the Stirling Broadcast cabinet, I'll follow the same construction and use 9mm, bitumen damped ply with a removable baffle.

Thankyou Colin

Despite some pretty dismal experiences with circa 2006 Jordans. I put this down to off shore QC issues. Ted Jordan remains one of the few to follow his convictions to the end come what may. In the back of my mind the allure of finding a full range that actually IS fullrange and delivers all the benefits while minimising the drawbacks has never quite left me.

Despite some pretty dismal experiences with circa 2006 Jordans. I put this down to off shore QC issues. Ted Jordan remains one of the few to follow his convictions to the end come what may. In the back of my mind the allure of finding a full range that actually IS fullrange and delivers all the benefits while minimising the drawbacks has never quite left me.

I think Vifa shifted production to India without telling anyone, hence the decision to search out manufacturing closer to home.

I've compared both Eikonas to the original JX92S (Europe-made version) and they are a lot cleaner at HF with a more balanced sound. The 2 is good in the BBC cabinet but, despite my preference for sealed, I think they'll work better in a vented box with more room to breath.

(Apologies for minor thread diversion.)

I've compared both Eikonas to the original JX92S (Europe-made version) and they are a lot cleaner at HF with a more balanced sound. The 2 is good in the BBC cabinet but, despite my preference for sealed, I think they'll work better in a vented box with more room to breath.

(Apologies for minor thread diversion.)

Hi

If memory serves me correctly HDF has exactly 3 times the density of MDF which sits around 50 lbs per cubic foot. I have owned speakers utilising Baltic Birch ply that correct me if I am wrong sits between 80 to 100 lbs per cubic foot depending on how far north up there they grow it. An engineer I know tested some MDF cabinets with a frequency generator and a lazer spectrometer. Not much between 20 & 200 Hz steadily rising to an 800 Hz peak plateuing out @ 1100-1200 Hz. I cannot supply you with any further details other than it confirms the previous comment of it "sucking the life out of the music" This can be engineered out in a small speaker but it is a lot of work. My ears tell me that the inertness of the cabinet is direcly related to density because guess what else has the density of HDF @ 150 lbs per cubic foot? CONCRETE! The problem with HDF at least here in Aust is health & safety (formaldehyde) binder and it EATS cutting and milling tools like mamma Cass on a Subway binge. So it is banned here but I managed to score a sheet before it all dissapeared. Sure Baltic is better than MDF and is more "Musical". My Tannoy Canterbury SE's were made out of it and would vibrate significantly at full throttle in my lounge 112-115 dB but it didn't ever seem to detract from the loud & clear big Tannoy's do so well. Higher density materials significantly ramp up production costs through cutting tool attrition and machine maintenence. Commercial products requre

clever engineering rather than brute force to keep production costs down. My ears suggest to me that HDF is the most neutral cabinet material. I will be applying some carbon impregnated bitumen internally soon to damp my 2 HDF cabs internally soon

If memory serves me correctly HDF has exactly 3 times the density of MDF which sits around 50 lbs per cubic foot. I have owned speakers utilising Baltic Birch ply that correct me if I am wrong sits between 80 to 100 lbs per cubic foot depending on how far north up there they grow it. An engineer I know tested some MDF cabinets with a frequency generator and a lazer spectrometer. Not much between 20 & 200 Hz steadily rising to an 800 Hz peak plateuing out @ 1100-1200 Hz. I cannot supply you with any further details other than it confirms the previous comment of it "sucking the life out of the music" This can be engineered out in a small speaker but it is a lot of work. My ears tell me that the inertness of the cabinet is direcly related to density because guess what else has the density of HDF @ 150 lbs per cubic foot? CONCRETE! The problem with HDF at least here in Aust is health & safety (formaldehyde) binder and it EATS cutting and milling tools like mamma Cass on a Subway binge. So it is banned here but I managed to score a sheet before it all dissapeared. Sure Baltic is better than MDF and is more "Musical". My Tannoy Canterbury SE's were made out of it and would vibrate significantly at full throttle in my lounge 112-115 dB but it didn't ever seem to detract from the loud & clear big Tannoy's do so well. Higher density materials significantly ramp up production costs through cutting tool attrition and machine maintenence. Commercial products requre

clever engineering rather than brute force to keep production costs down. My ears suggest to me that HDF is the most neutral cabinet material. I will be applying some carbon impregnated bitumen internally soon to damp my 2 HDF cabs internally soon

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Rogers 3 5A diy kits