With usual electroplated PTH boards eyelets are not necessary , they are used only in some home made double sided PCB-s. I think that DVV described normal PTH PCB, not riveted DIY prototype.The rest of the electronics world struggles with normal PCBs and normal PTH holes, no need for outdated techniques really, but this is audio an I believe sometimes that certain areas of audio exists in the twilight zone

Audio Research prefers PCB-s without any solder mask.

And this sort of recording is gold, for me ... I'm not familiar with this album, but I have another Joe Williams compilation that has a similar sound. A terror ride for a normal system, every tiny aberration in the playback chain will be intensely magnified, they are a brilliant, high powered spotlight, pointing to all the problems.Off topic, but I was just brought face to face or ear to ear with how terrible-sounding early solid-state could be. The item was an otherwise excellent album with Joe Williams and the Thad Jones-Mel Lewis aggregation. It had an instant family resemblance to what I think was the first album in the series that touted the electronics. I do not know the specific console(s) used.

Of course most of this could be due to miking, but I doubt it.

These albums are fabulous to listen to when a system is sorted - intense, powerful, the best sort of musical journey,

As I usually do, I pick up specific test equipment to learn and see what affects this/that have then get rid of it. For jitter, I have on order the Yokogawa TA320. It will measure jitter and give a distribution plot.... down to +/- 100pSec full scale. I will see what i have and how to improve it.... also what makes it worse and how much worse. Enough about what perfect communications theory and other such ideal conditions and the like says. I'm sure to learn a lot about all sorts of things with it re jitter.

THx-RNMarsh

Plenty of info regarding jitter for communication systems, such as long range ones, then there is DDR memory interfaces and a wealth of other interfaces where jitter can be a problem. It is a well studied problem, both causes and solutions. Oh frequency hopping communications is another area...

The problem with eyelets is the PCB- difference of the coefficient of thermal expansion and creep between PCB and metal are not conducive to long term reliability.

I was rather shocked that apart from repairs they are still used... PCBs are reliable enough if sourced and specified properly, and it is the latter that I do think is lacking somewhat from the replies I have read regarding PCBs. Things would be easier if some didn't just decry FR4 as bad when they don't really understand todays PCBs and materials.

References for copper porosity and hydrogen incorporation..

S. Nakahara, Thin Solid Films, 45, 421 (1977).

S. Nakahara, Thin Solid Films, 64, 149 (1979)

References for increased resistivity..

J. C. Patterson, M. O’Reilly, G. M. Crean, and J. Barrett,

Microelectron. Eng., 33, 65 (1997).

S. Lopatin, Y. Shacham-Diamand, V. M. Dubin, P. K. Vasudev,

B. Zhao, and J. Pellerin, in Electrochemically Deposited Thin

Films, M. Paunovic and D. A. Scherson, Eds.,Proceedings, Vol.

19, Electrochemical Society, Pennington, NJ, 1997, p. 271.

M. Dubin, Y. Shacham-Diamand, B. Zhao, P. K. Vasudev, and

C. H. Ting, J. Electrochem. Soc., 144, 898 (1997)

Tohru Hara, Satoshi Kamijima, and Yasuhiro Shimura

Electroplating of Copper Conductive Layer on the Electroless-Plating Copper Seed Layer

Electrochem. Solid-State Lett. 2003 6(1): C8-C11

Not true any more many laminates and flexis are made with electroless deposited copper.... They use to calculate current capacity different for the electroless copper don't any more because it carries the same current... and processes have improved. When I get chance I will try and find the documentation regarding current capacity, and a few pages (!) back I posted an article showing the various forms of copper used on PCBs.

A long time ago before we went to PTH and CAD, we used to use these Harwin via pins.

https://www.harwin.com/products/T1559-01/ still available, worked very well and easy to use.

https://www.harwin.com/products/T1559-01/ still available, worked very well and easy to use.

Thinking about adding jitter to a file, I guess since you know what the wave shape is intended to be, then you could calculate what the sample obtained would be if the sampling instant is moved. So you end up with a different bunch of numbers.

I really bring this up because I think in some quarters that the mechanism whereby jitter is embedded in a file amounts to something more than a different bunch of numbers in the result.

Which is kind of different from what we might attempt in playback, where you might think more in terms of running the DAC from a VCXO and modulating that, but we're saying that it's equivalent in effect.

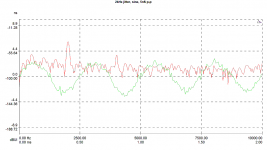

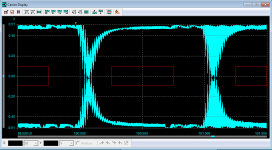

Spend some time yesterday with the dScope on how to generate a stream with jitter. The attached are some views of a 1kHz signal with a 2kHz 5n peak-peak jitter. The 'analog' graph does NOT show the analog signal: it is a view of the jitter content in the data stream, demodulated and processed in one channel of the analog analyser. You see the 2kHz jitter modulation in both the time and freq domain in the same graph - I think that's a neat way to combine two views.

The eye diagram also shows (red rectangles) the minimum requirements for AES3 signals and you can see that with this 5nS p-p jitter there's no problem at all.

I will play with it some more and then insert a DAC to see what this jitter does to the DAC output. Question to answer: what kind of jitter would be representative for 'typical' CD transports and downloaded streams? Most certainly not just 2kHz. I can use a variety of jitter signals, even noise-like.

Jan

Attachments

Last edited:

References for copper porosity and hydrogen incorporation..

Electrochem. Solid-State Lett. 2003 6(1): C8-C11

Having a quick look, the final resistivity of electroplated copper can be dependant on the seed layer, current density, this also influences grain size with larger grains having the highest resistance. Purity is pure copper.

I will look through the papers you posted and others that I have, one or two in particular from around 2000 regarding current carrying capacity of PCBs. Again there have been improvements in processes over the years and the quality has improved due to demand, mainly for thin laminates for very fine line design and flexis.

Plenty of info regarding jitter for communication systems, such as long range ones, then there is DDR memory interfaces and a wealth of other interfaces where jitter can be a problem. It is a well studied problem, both causes and solutions. Oh frequency hopping communications is another area...

yes, they are..... just not in MY home listening system. And, I want to verify the difference between the CD and HD downloads.... jitter-wise. Then I'll see if I want to bother with trying to reduce the jittter for CD.

THx-RNMarsh

Last edited:

I did hear an audible change when such oscillator was fitted into 'all in one' CD player or external A/D converter, thou. For me personally, before/after change was huge, for some others it might not matter ;-)

-RNM

The rest of the electronics world struggles with normal PCBs and normal PTH holes, no need for outdated techniques really, but this is audio an I believe sometimes that certain areas of audio exists in the twilight zone

Marce, I am a lazy sod and do not like to struggle. In my view, the price premium is meaningless for my peace of mind. The technique may be outdated, but I think few can argue that it produces good results.

Last, but certainly not least, I have to work with what I have, not with the latest technical achievements, which are not available to me at anything even near the local prices. The epoxy boards are made from German made materials, no Chinese thank you, so at least I'm good in that respect.

There is/was a Marconi spectrum analyser, quite a good spec, but had hundreds of those eyelets, after a while they usually went bad, and some poor technician would have to spend a couple of days or so soldering them all up to get rid of the intermittent issues they caused.

Perhaps so, but I vouch that was because the inital work was below par. Boards I made with that technology never once failed since 1980. Most of the problems I ever had were due to below par soldering quality delivered by machines. Not as easy as it may appear. All it takes is a cost conscious manufacturing department and you could be in big trouble, either due to low cost soldering wire, or by having the soldering adjusted for minimum cost.

I use British made soldering wire, which is said to contain 9% of silver, the only alternatve being German made Flutin. Never a hiccup from either of them.

Marce, I am a lazy sod and do not like to struggle. In my view, the price premium is meaningless for my peace of mind. The technique may be outdated, but I think few can argue that it produces good results.

Damian, I am affraid I will have to subject you to some bias adjustment: as a matter of fact, quite a few have argued that it does not produce good results.

With usual electroplated PTH boards eyelets are not necessary , they are used only in some home made double sided PCB-s. I think that DVV described normal PTH PCB, not riveted DIY prototype.

Audio Research prefers PCB-s without any solder mask.

You are right on several counts.

First, I use by deault double sided PC boards, because I have a pathological hate of jumpers, even one is one too many for me. Also, top side is generally used for ground planes.

And second, I never ever make my PC boards myself, for that I go to the professionals, in my case Tibor from Subotica. In over 20 years of buying from him, I have never experienced any trouble, technical or commercial from him and I'd like to keep it that way. Oviously, that costs more than if I id it myself, but this way the question of consistency is a non issue.

Last edited:

Damian, I am affraid I will have to subject you to some bias adjustment: as a matter of fact, quite a few have argued that it does not produce good results.

Er, Vacc? Sorry to bother, but I am not Damian (I leave that to Audio1), I am Dejan (pronouced as Day-un).

I am well aware of what people said about it. Unfortunately, their experiences are in complete opposition to my own experiences, and I will not change how I do it until my experiences are changed. It works wonderfull with me, and I stick to the old rule - if it ain't broken, don't fix it.

For example, some crticized Philips for their manufacturing practices. In my 62 years of life, I have never had any Philips sourced device, audio, video or otherwise, die on me, or urgently require service. Perhaps I was one of the lucky ones, I don't know, but I am used to having Philips products work and work. My late father's Philips rotary shaver, purchased in Munich in 1956, still works flawlessly. My only complaint is that Philips uses very short lived rechargeable batteries in their later models, they typically die within a year, so you have to buy new ones. A nice way of milking one's customers.

Last edited:

yes, they are..... just not in MY home listening system. And, I want to verify the difference between the CD and HD downloads.... jitter-wise. Then I'll see if I want to bother with trying to reduce the jittter for CD.

THx-RNMarsh

The causes and solutions to jitter are the same though, there is no basic difference in the mechanisms of transmitting digital data be it audio streem, data to a memory bank of communication data. You said you wanted to explore the causes of jitter...

For example, some crticized Philips for their manufacturing practices. In my 62 years of life, I have never had any Philips sourced device, audio, video or otherwise, die on me, or urgently require service.

You've never worked in a busy service dept then

Philips loved 1.2 and 2.4 volt rechargeables for memory retention. They had a life of around 12 to 18 months. That said I have an early Philips FST 15" that I fitted a 3 volt lithium coin watch cell some 18 years ago. Its still going strong (the TV and the cell).

Sorry Dejan (and Demian) for mixing up your names.

Not to worry, no big deal. No harm done.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II