Oh sure, these guys published BS in a $210 book. '-)

I thought you said you bought it used. Somebody took you for a ride John.

Seriously though, you really think defects caused by a hard physical process on the edge of a thin film has anything to do with how a 12 guage ETP copper wire conducts electricity?

I've got a bridge to sell you.

jn

Here are two pages. The second page states that the mechanism is NOT due to the Electron microscope, so there! '-)

Where does it say this has anything to do with audio?

Seriously though, you really think defects caused by a hard physical process on the edge of a thin film has anything to do with how a 12 guage ETP copper wire conducts electricity?

Since John likes fishing through book indexes to try to baffle people with irrelevancies, he ought to start talking about surface plasmons. It sounds much cooler than "grain boundaries."

I'll expect a commission check.

That was the NEW price for the book. Perhaps you out there should invest in such books.

As opposed to going to the cafeteria and asking the leading edge researchers?

Well, I guess buying used books is good enough for people like you..I prefer being far more advanced in my understandings.

I just went through a 1942 book on lathe principles, and another on watchmakers lathes...I love old books, so much has been lost.

jn

Since John likes fishing through book indexes to try to baffle people with irrelevancies, he ought to start talking about surface plasmons. It sounds much cooler than "grain boundaries."

I'll expect a commission check.

How bout a question instead.

english (metric), or metric (english)??

I prefer the first, as I'm on this side of the pond...

jn

I used to be responsible to maintain and was intimately familiar with a one-off SEM for the Chemistry guys at LLNL ..... It didnt destroy nor damage nor alter the surface of the object being scanned in any way.

In fact, if it did so via heat etc, it would have blown up the SEM's LN cooled input detector as they were looking at unburnt High Explosive material (HE)!

THx-RNMarsh

In fact, if it did so via heat etc, it would have blown up the SEM's LN cooled input detector as they were looking at unburnt High Explosive material (HE)!

THx-RNMarsh

Last edited:

How bout a question instead.

english (metric), or metric (english)??

I prefer the first, as I'm on this side of the pond...

Do the second. There's about 6.5 billion people out there, of whom 6.2 billion use metric.

Burn-in of audio electronics is based on physics, rather than engineering. Cryoing does something similar and can speed up the burn-in time if used.

Please educate us...

I used to maintain and was intimately familiar with a one-off SEM for the Chemistry guys at LLNL ..... It didnt destroy nor damage nor alter the surface of the object being scanned in any way.

In fact, if it did so via heat etc, it would have blown up the SEM's LN cooled input detector as they were looking at unburnt High Explosive material (HE).

Metals vs. organics. Electron energies?

I used to maintain and was intimately familiar with a one-off SEM for the Chemistry guys..... It didnt destroy nor damage the surface of the object being scanned.

In fact, if it did so, it would have blown up the SEM's LN cooled input detector as they were looking at unburnt High Explosive material (HE).

THx-RNmarsh

When looking at edge structures that require very little energy input to change state (room temp sufficing for the purpose), an e-beam can certainly be of concern. We're not talking about frying samples, just playing with lattice strains and defects.

edit: how did they keep it in focus? Did they coat the samples with carbon first, or were the samples conductive?

Do the second. There's about 6.5 billion people out there, of whom 6.2 billion use metric.

While I tend to agree with your statement, I still hate you.

jn

What is the maximum SPL, at 100Hz? (for Quad)

QUAD test are at 100dB/1m. You can read the full test report in an Issue of Stereophile on their web site.

-RM

JN,

When I come across it in my storage I have an old metal belt driven watchmakers lathe you could have. Don't know when I will see it but when I do it is yours. I gave an entire watch and clockmaker's tool set to a museum somewhere in Santa Barbara, CA. I have a nice grandfather clock I need to fix, haven't worked on anything like it but used to fix pocket watches when I was much younger.

When I come across it in my storage I have an old metal belt driven watchmakers lathe you could have. Don't know when I will see it but when I do it is yours. I gave an entire watch and clockmaker's tool set to a museum somewhere in Santa Barbara, CA. I have a nice grandfather clock I need to fix, haven't worked on anything like it but used to fix pocket watches when I was much younger.

While I tend to agree with your statement, I still hate you.

Get in line.

When looking at edge structures that require very little energy input to change state (room temp sufficing for the purpose), an e-beam can certainly be of concern. We're not talking about frying samples, just playing with lattice strains and defects.

edit: how did they keep it in focus? Did they coat the samples with carbon first, or were the samples conductive?

While I tend to agree with your statement, I still hate you.

jn

It did not happen.... I could see down to a cluster of atoms -- a molecule !

The sample was coated (one molecule thick) with various pure metals for various reasons and materials being observed. Gold was one of them.

The key, I found, much to the Chemists delight, was the zero offset in the direct coupled amps needed to be rezeroed from time to time (I had not invented the concept of dc-servo those circuit, yet). So tell your tech support to dc zero the thing's every amp stage. Have them make it a regular scheduled part of a calibration process. That alone should be good for a salary raise.

THx-RNMarsh

Last edited:

You can read the full test report in an Issue of Stereophile on their web site.

-RM

Nice impulse response and square w transfer. I like it. I also have 'something' interesting.

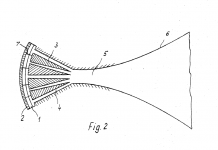

... ( US3590169 )

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II