I have tested the following Autotech JMLC horns extensively;

JMLC-200 (With a Choice selection of 8" wideband elements)

JMLC-200T

JMLC-270

JMLC-350

JMLC-400

Drivers have varied between Altec 288, TAD TD-2001, 2002, 4001, ALE4550, ALE7550.

The smoothness in response, lack of any colorations, and negligible distortion is simply stunning. Add to that fine craftsmanship and no resonances, super service and all possible flanges for Connections available and you get the Picture. Even hardcore horn fiends have commented on their ability to just disappear and even produce a superb 3D image.

Highly recommended.

JMLC-200 (With a Choice selection of 8" wideband elements)

JMLC-200T

JMLC-270

JMLC-350

JMLC-400

Drivers have varied between Altec 288, TAD TD-2001, 2002, 4001, ALE4550, ALE7550.

The smoothness in response, lack of any colorations, and negligible distortion is simply stunning. Add to that fine craftsmanship and no resonances, super service and all possible flanges for Connections available and you get the Picture. Even hardcore horn fiends have commented on their ability to just disappear and even produce a superb 3D image.

Highly recommended.

Attila from Hungary can make any horn you dream of from wood of your choice. I avoid plastic if I can and the prices are right . He advertises on AA. He is competitive even with shipping to US .In EU it's a steal :

JMLC 1000 1000 Hz JMLC 1000 from maple for sale - Audio Asylum Trader

JMLC 1000 1000 Hz JMLC 1000 from maple for sale - Audio Asylum Trader

And what were your impressions of these drivers? If you live in the Oslo area we could add the JA-6681A and a new Radian 750-8, and Avantgarde Trio's Community M200 8ohm (not M200A) to the list. I am soon finished with a homemade Goto S150 horn, but it is pretty huge. 1.5m x 80cm

Last edited:

I have tested the following Autotech JMLC horns extensively;

JMLC-200 (With a Choice selection of 8" wideband elements)

JMLC-200T

JMLC-270

JMLC-350

JMLC-400

Drivers have varied between Altec 288, TAD TD-2001, 2002, 4001, ALE4550, ALE7550.

The smoothness in response, lack of any colorations, and negligible distortion is simply stunning. Add to that fine craftsmanship and no resonances, super service and all possible flanges for Connections available and you get the Picture. Even hardcore horn fiends have commented on their ability to just disappear and even produce a superb 3D image.

Highly recommended.

I am strongly considering the 400. Do you, by chance, have s frequency plot with the 288 installed.

I am strongly considering the 400. Do you, by chance, have s frequency plot with the 288 installed.

Unfortunately not, but I strongly recommend the 350 - of course depending on Your xover target, if it is closer to 1k it really doesn't matter that much. My personal fav for large format drivers is the 270 - Works fine all the way Down to 500 Hz and is the ideal partner. The 200T/288 combo has frightening grunt and groan even Down to 350 Hz but has no business above 6k. and it is awfully big and Heavy.

For a very compact system the JMLC-400 is excellent for 1" format drivers.

Would you not recommend the 288/400 to be crossed at 650, like Lynn has done with the Azura 425?Unfortunately not, but I strongly recommend the 350 - of course depending on Your xover target, if it is closer to 1k it really doesn't matter that much. My personal fav for large format drivers is the 270 - Works fine all the way Down to 500 Hz and is the ideal partner. The 200T/288 combo has frightening grunt and groan even Down to 350 Hz but has no business above 6k. and it is awfully big and Heavy.

For a very compact system the JMLC-400 is excellent for 1" format drivers.

Pano,

If i ever get around to finishing the Altecs and putting the 288 on the jmlc400, you are welcome to have a listen. It wouldnt hurt to have an experienced Altec ear

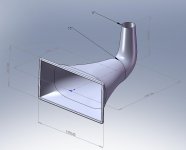

Hi jzagaja, Your horns look beautiful - very high production standard. Would you like to tell us anything about how they are made? How did you make the moulds? Did you CNC machine to the JMLC curve?

I understand from the website that they are fibreglass - is this a traditional hand layup? Or are you using some kind of infusion method? Any plans to do injection moulding and mass produce? I guess insufficient market. How do you get the throat accurate and make the flanges?

You have perhaps seen my own very amateur 'analogue' diy method on azurahorn.com. (Trade Secrets) It works very well, given care - but quality control is always the thing with entirely skill based traditional fibreglass.

Interested in how you have solved the problems, nice job.

best wishes, martin

I understand from the website that they are fibreglass - is this a traditional hand layup? Or are you using some kind of infusion method? Any plans to do injection moulding and mass produce? I guess insufficient market. How do you get the throat accurate and make the flanges?

You have perhaps seen my own very amateur 'analogue' diy method on azurahorn.com. (Trade Secrets) It works very well, given care - but quality control is always the thing with entirely skill based traditional fibreglass.

Interested in how you have solved the problems, nice job.

best wishes, martin

Thanks  Autotech uses CNC machine to make a mold:

Autotech uses CNC machine to make a mold:

http://autotech.pl/pdf/firma.pdf

JMLC horn requires two molds - one for rollback and one for horn. It is traditional hand layup plus damping layer if required. SEOS-12 is also made out of solid surface (closed mold). Similar waveguide was mass produced by Diysoundgroup in China by using injection moulding.

Your work is beautiful and shows that no fancy tools are required.

http://autotech.pl/pdf/firma.pdf

JMLC horn requires two molds - one for rollback and one for horn. It is traditional hand layup plus damping layer if required. SEOS-12 is also made out of solid surface (closed mold). Similar waveguide was mass produced by Diysoundgroup in China by using injection moulding.

Your work is beautiful and shows that no fancy tools are required.

Thanks  . I looked at doing infusion, with a front and back mould, or vacuum bagging, but it was too hard to set up. I think it could be done if one had time and resources to get it right. The next step would be to set up temperature controlled bath and control the process. Composites technology has developed a long way in the aircraft industry, but hard to get beyond traditional layup without big investment. I think your damping layer sounds really good. Few people perhaps realise how much work goes into this.

. I looked at doing infusion, with a front and back mould, or vacuum bagging, but it was too hard to set up. I think it could be done if one had time and resources to get it right. The next step would be to set up temperature controlled bath and control the process. Composites technology has developed a long way in the aircraft industry, but hard to get beyond traditional layup without big investment. I think your damping layer sounds really good. Few people perhaps realise how much work goes into this.

martin

martin

Truetone,

Being from a tooling background in aerospace I can tell you that the advantage of using those methods for building horn lenses is not going to be that great. Mainly you would have less hassles with any chance of pinholes and the resin content to fiber ratio would change as any excess resin would be removed. But at the same time you would not be using any polyester resin in an aerospace application, everything is epoxy and this rules out using any glass mat, everything is done with only woven fibers rather than random fiber mat materials. Also we do not use gel coats, that just isn't done so you would lose that type of finish, I am sure you have seen carbon fiber parts with the fiber showing and this is what you would be looking at. RTM of the many different methods would also be done this way with no gel coat surfaces. I have done development work in closed tool molding of high speed composites and again there is never a gel coat though you can use an in-mold coating. Tooling would get rather expensive in any of these types of applications and unless you are talking serial molding of high volume not the most cost effective way to go.

Being from a tooling background in aerospace I can tell you that the advantage of using those methods for building horn lenses is not going to be that great. Mainly you would have less hassles with any chance of pinholes and the resin content to fiber ratio would change as any excess resin would be removed. But at the same time you would not be using any polyester resin in an aerospace application, everything is epoxy and this rules out using any glass mat, everything is done with only woven fibers rather than random fiber mat materials. Also we do not use gel coats, that just isn't done so you would lose that type of finish, I am sure you have seen carbon fiber parts with the fiber showing and this is what you would be looking at. RTM of the many different methods would also be done this way with no gel coat surfaces. I have done development work in closed tool molding of high speed composites and again there is never a gel coat though you can use an in-mold coating. Tooling would get rather expensive in any of these types of applications and unless you are talking serial molding of high volume not the most cost effective way to go.

Pano, if I ever get around to finishing the Altecs and putting the 288 on the jmlc400, you are welcome to have a listen. It wouldn't hurt to have an experienced Altec ear.

When the colorations that we associate with high-efficiency speakers are removed, the sound becomes really transparent and dimensional. Very small changes (one component) in the source electronics become obvious, akin to Stax electrostatic headphones, but instead of the sound being trapped in your head, it's very large and room-filling. One of the more startling effects is the soundstage coming up to your knees, as well as disappearing behind the far wall.

The colorations that are present in horns with time-domain reflections mask the 3D presentation and electrostatic-like resolution that is possible with good compression drivers. It's an interesting experience to hear Altec/GPA tonal vividness without the midrange forwardness (and shout) of traditional 511 and 811 sectoral horns.

You get used to the audiophile special effects fairly quickly, and they fall by the wayside. The main attraction are the shimmering tonal colors, the hallmark of good high-efficiency loudspeakers, and something that is so noticeably absent in audiophile speakers with efficiencies in the 85~88 dB/meter range.

Last edited:

jzagaja, yes, I still use 50Hz horns, now cut down to 1.7m length and with Vitavox K15/40 drivers, open backed. I find these to be much more in tune with the mid / upper horns - I don't hear any difference or join. I tried Onkens with same drivers (also had opportunity to try AES TT15M and GOTo 15" drivers on both horns and Onkens) - the Onkens have more 'rock and roll' impact (my son has them and loves them), but the bass horns give you more of what Lynn describes so well. They do double bass or piano low notes really well. Not sure anything so uncontrolled could be called accurate, but I have stopped worrying and just enjoy them.

martin

martin

When the colorations that we associate with high-efficiency speakers are removed, the sound becomes really transparent and dimensional. Very small changes (one component) in the source electronics become obvious, akin to Stax electrostatic headphones, but instead of the sound being trapped in your head, it's very large and room-filling. One of the more startling effects is the soundstage coming up to your knees, as well as disappearing behind the far wall.

I recently fnished an Onetics based SS amplifier that is the frst amp I have built that really achieves this type of presentation. It is my hope that the Altec setup will further improve or enhance this experience.

Just let me know. I'll drive on over.Pano,

If i ever get around to finishing the Altecs and putting the 288 on the jmlc400, you are welcome to have a listen.

jzagaja, yes, I still use 50Hz horns...

We wil test 50Hz hypex t=0,3 soon - for 8, 12 or 15".

Attachments

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel