I just cannot see me making those with a cheap panel saw and a box of 4inch nails

Cut-and-glue from best DIY sites.

Today, many 10" midbass get mated to compression driver horns (90x40 common like SEOS12 and EJMLC600) in EcoWave rectangular cabinets using just fiberglass stuffing.

Attachments

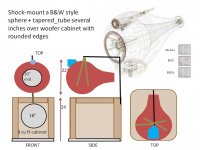

I think the ideal midbass cabinet is shaped like a sphere to allow the cone rear wave DYNAMICS to EXPLODE without interference and then get quickly absorbed without any resonance by a stuffed, tapered rear cavity with a tiny open exit. With a sphere, diffraction is almost ideal but a difficult shape to construct and integrate into a multi-way speaker.

B&W 801 genius engineers did their homework. Avalon genius engineers, Focal Grande Uotopia, WhiteLight engineers worry about rear waves and diffraction using more standard construction.

But that box is that large with just the midrange, then wouldn't a midbass @ 80 hz cutoff have to be huge? And from their own site they speak that the advantage ( or disadvantage ) of the nautilus horn is in the high frequencies and shouldn't that be higher than 400-500 hz?

Last edited:

But that box is that large with just the midrange, then wouldn't a midbass @ 80 hz cutoff have to be huge? And from their own site they speak that the advantage ( or disadvantage ) of the nautilus horn is in the high frequencies and shouldn't that be higher than 400-500 hz?

You are correct.... it would be bigger than a breadbox

Most 10" midbass cabinets use large radius quarter round edges, or mitered front angles as shown earlier, with extensive fiberglass stuffing. For midbass, fiberglass stuffing measures best attenuation. Baffle simulation programs and DIY measurements(Aerial thread) show value in diffraction control down to 80Hz. AE Speakers use large radius quarter rounds on their bass cabinets.

Attachments

Hello there all you box experts.

I'm planning to test build a sealed midwoofer @ ~ 80-500 hz and I'm wondering about the box.

What is the best enclosure design for completely suppressing the back wave and thus approximate an infinite baffle? I will go active with DSP so Q, low end response and easily fixable resonances can be ignored.

// The Olle with the insatiable hunger for knowledge

Hi,

I'd minimise the cabinet signature using a small sealed and well stuffed box.

Add bracing and use that to breakup / complicate the rear wave somewhat.

rgds, sreten.

So the conclusion we can make from this elegant analysis is that the pipe absorbs the back wave to 1/5th the frequency of the cube. And since the question under scrutiny is how to attempt to absorb all of ths back wave, then we can look at the pipe as having considerably larger bandwidth.

dave

If you want to look at it that way then you need to worry about the higher reflection frequency of the long tubes narrower other two dimensions (assuming we have a fixed target volume).

The analysis is correct. We want to deal with the artifacts of dimension which are the 1/2 wave resonance. Below that frequency there is no issue. For long wavelengths the enclosure is everywhere in phase and acting purely as an enclosed volume.

Physics.

David S.

I'm no expert in acoustics, perhaps David or someone else might have something to say about this.

I've been told once that the idea behind the B&W tube is to gradually decrease the area of the tube trough which the backwave travels, in order to gradually increase particle velocity relative to a "normal" non-tapered enclosure. The idea was that this should slightly increase the effectiveness of the damping material in the enclosure while decreasing the reflection at the back of the enclosure.

Any comments?

I've been told once that the idea behind the B&W tube is to gradually decrease the area of the tube trough which the backwave travels, in order to gradually increase particle velocity relative to a "normal" non-tapered enclosure. The idea was that this should slightly increase the effectiveness of the damping material in the enclosure while decreasing the reflection at the back of the enclosure.

Any comments?

I'm no expert in acoustics, perhaps David or someone else might have something to say about this.

I've been told once that the idea behind the B&W tube is to gradually decrease the area of the tube trough which the backwave travels, in order to gradually increase particle velocity relative to a "normal" non-tapered enclosure. The idea was that this should slightly increase the effectiveness of the damping material in the enclosure while decreasing the reflection at the back of the enclosure.

Any comments?

I can't comment on the particle velocity increase, but I'm not sure it works that way. Most of the drawings of the 801 head show a ray tracing approach with a shape optimized to get driver rays, from all directions, eventually back to the little hole in the back (and what the sound does there is anybodys guess, but it will include reflection).

B&W has never let proper engineering get in the way of a good marketing story.

Ray tracing is well known and used in architectural acoustics but it does have its limitations. It assumes specular reflection (like a light ray off of a mirror) and it ignores diffraction. As such it is only accurate for higher frequency modeling and presumed smooth surfaces.

If we never put surface absorption (or used very poor material) then any approach that forced more bounces away from the cone might have a benefit in at least delaying the back reflection. Without absorption the energy will eventually and certainly return, even with the most clever interior shape. Start adding high performance absorption material and these complex shapes become irrelevant.

I don't know who else here has ever measured absorbant material? I have. The most revealing test is to drill a 1/2" hole in the corner of a woofer box and measure the internal pressure. While the cabinet is bare you will see every standing wave. As you start to line the surfaces with material the upper resonances will drop first. Assumng your material is a good absorber (not dacron fluff, polyester stuffing or other pillow materials) you can make all the evidence of standing waves disappear with sufficient stuffing. The only time I've had trouble with a residual standing wave was a tall tower with the woofer at the top. A lined cabinet didn't fully deal with it, but placing a damping partition half way up (at the velocity maximum) did.

David S.

You are correct.... it would be bigger than a breadbox

Most 10" midbass cabinets use large radius quarter round edges, or mitered front angles as shown earlier, with extensive fiberglass stuffing. For midbass, fiberglass stuffing measures best attenuation. Baffle simulation programs and DIY measurements(Aerial thread) show value in diffraction control down to 80Hz. AE Speakers use large radius quarter rounds on their bass cabinets.

Hmm, I've just thought some more about this kind of design...

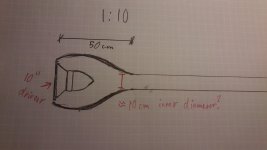

Or rather the dimentions of it. I'm toying with the idea of making a bullet enclosure like in the image and then fitting a sewer pipe on the other end.

The question is how large the rear pipe diameter has to be though... could I get away with a pipe with ~ 10 cm inner diameter when placed about 40 cm away from the driver like in the picture or would I need a larger diameter on the pipe?

In practice the rear pipe would be bent of course, those nice buyable 90 degree angles sure look interesting and probably much easier and better to use than trying to build my own snail shaped box

Attachments

Or rather the dimentions of it. I'm toying with the idea of making a bullet enclosure like in the image and then fitting a sewer pipe on the other end.

Make sure you connect a proper trap before connecting it to the local sewer. Otherwise there is a real chance of fumes getting back into the house. Most houses use a 4" service.

Regards

Attachments

Make sure you connect a proper trap before connecting it to the local sewer. Otherwise there is a real chance of fumes getting back into the house. Most houses use a 4" service.

Make sure you connect a proper trap before connecting it to the local sewer. Otherwise there is a real chance of fumes getting back into the house. Most houses use a 4" service.

Regards

lol, we should make subs like this to see if we can get water to come back up out of the sinks on low bass notes.

Member

Joined 2009

Paid Member

So if I built a sub...say using one of those monster stroke 18" ones for cars...

Attached the port to a plunger and played the thing at it's tuning frequency...

I can blow out the clogs?

Acoustic Plumber... clears the clogs and great for movie theater explosions.

Maybe a band pass type box would be better with an aluminum cone woofer, that way if it sucks up liquids--easier to clean without damage.

Attached the port to a plunger and played the thing at it's tuning frequency...

I can blow out the clogs?

Acoustic Plumber... clears the clogs and great for movie theater explosions.

Maybe a band pass type box would be better with an aluminum cone woofer, that way if it sucks up liquids--easier to clean without damage.

What about a normal box, with plenty of fiberglass filling....?

http://www.owenscorning.com/comminsul/documents/Fiberglas700Series.pdf

http://www.owenscorning.com/comminsul/documents/Fiberglas700Series.pdf

I remember watching a video on the B&W website about the development of the 800 series, and why half wave TL's are problematic for wide band drivers here you go:

http://www.bowers-wilkins.co.uk/Sphere-Tube.html

They took down their very interesting while paper on the 800, but you can find it here:

http://www.fransvaneeckhout.be/800_Development_Paper.pdf

A pain in the *** to make for the DIYer, which is why I've never fooled around with it, but could be a interesting journey!

http://www.bowers-wilkins.co.uk/Sphere-Tube.html

They took down their very interesting while paper on the 800, but you can find it here:

http://www.fransvaneeckhout.be/800_Development_Paper.pdf

A pain in the *** to make for the DIYer, which is why I've never fooled around with it, but could be a interesting journey!

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Best sealed enclosure for completely supressing back wave

![1616s[1].jpg](/community/data/attachments/275/275162-bab0d99d9238fb3244d39e9f15c93d98.jpg)