thought I would put this link up. They sell some adhesive PCB pads and lines, curve sectons, etc. Not dry transfer but it may work. All under prototyping supplies.

Dave

http://www.minute-man.com/acatalog/...t__Exposure_Kit__Etching_Solutions___245.html

Dave

http://www.minute-man.com/acatalog/...t__Exposure_Kit__Etching_Solutions___245.html

easier etchant

The only problem with this etchant is that the 35% food grade hydrogen peroxide is considered to be a hazardous substance in the same class as ferric chloride. Also you can find the 35% hydrogen peroxide from suppliers on the internet, but rarely from a brick and mortar in your area. So substituting the above etchant for ferric chloride doesn't get you out of the mess of high cost and lack of availability locally.

Is there any way that the lower percent hydrogen peroxide that is widely available at pharmacies could be made more potent or in some way used to make the 1 part muriatic acid, 1 part hydrogen peroxide, 1 part tap water? Muriatic acid is pretty much widely available from for example Home Depot and also I believe used for treating the water of swimming pools.

Regards, Pete

Then, the board is set aside to dry as I prepare the etchant. I use 2 parts hardware-store muratic acid mixed with 1 part 35% food grade hydrogen peroxide (thank you, internet) and 1 part plain ol' tap water. Enough of this is prepared to fill a Pyrex baking dish about 1/2", and stirred around with a plastic straw.

The only problem with this etchant is that the 35% food grade hydrogen peroxide is considered to be a hazardous substance in the same class as ferric chloride. Also you can find the 35% hydrogen peroxide from suppliers on the internet, but rarely from a brick and mortar in your area. So substituting the above etchant for ferric chloride doesn't get you out of the mess of high cost and lack of availability locally.

Is there any way that the lower percent hydrogen peroxide that is widely available at pharmacies could be made more potent or in some way used to make the 1 part muriatic acid, 1 part hydrogen peroxide, 1 part tap water? Muriatic acid is pretty much widely available from for example Home Depot and also I believe used for treating the water of swimming pools.

Regards, Pete

You may find an answer in the Yahoo group "Homebrew_PCBs" at < Homebrew_PCBs : Homebrew Printed Circuit Boards >.

Dale

Dale

Searching with Google, I found a certain Thomas P. Gootee who claims success with an etchant that is 1 part Muriatic Acid to 2 parts 3% hydrogen peroxide. See Easy PCB (Printed Circuit Board) Fabrication, Using Laser Printer Toner Transfer, with a Household Clothes Iron and Glossy Inkjet Photo Paper; DIY at Home; Better AND Cheaper than Press-n-Peel ( PnP / P-n-P )! Making, Cheap , Economical , fastest fas

I think that I will give this a try (the 3% hydrogen peroxide). Has anyone else tried Mr. Gootee's mix?

Regards, Pete

I think that I will give this a try (the 3% hydrogen peroxide). Has anyone else tried Mr. Gootee's mix?

Regards, Pete

This is my very first board I just did yesterday and works perfect. I designed it in Eagle, then drew with a permanent marker and put it in ferric chloride. Worked in about 20 minutes (heated the solution a bit) and stired all the way. I'm very pleased with the result. It is a HT regulator for my bevois valley clone, i used more parts (didn't have the right resistor values) and everything worked out great. Except for the fact that I think I got more ohms in the end vs the breadboard  ) as the voltage dropped about 4V from 284V.

) as the voltage dropped about 4V from 284V.

An externally hosted image should be here but it was not working when we last tested it.

Is there any way that the lower percent hydrogen peroxide that is widely available at pharmacies could be ... used to make the 1 part muriatic acid, 1 part hydrogen peroxide, 1 part tap water?

Yeah, the concentration of hydrogen peroxide is not critical, you can leave out the tap water (I would anyway even with 35%, although I've only ever used stuff from the pharmacy, I buy the strongest they have at the time). As the solution is used it will go blue then darker green but can be regenerated by the addition of peroxide (goes back to blue) or even, I believe, by bubbling air through it, although I'm usually in too much of a hurry and just add peroxide (and sometimes some acid). I've got no idea the relative concentrations in my current brew which is gradually growing in volume.

I prefer this to ferric chloride or ammonium persulphate because of its local availability. Beware, it causes persistent green staining on some materials or even rots cloth (as opposed to the yellow stains from ferric).

I use 3% hydrogen peroxide from the drug store + 31.45% hydrochloric acid from the pool supply shop, with plastic containers and utensils. A 2:1 mix sounds right. I use some small plastic tongs to "shake" the board a little every so often, and it's fairly easy to see the etch progressing. For five bucks you an etch a lot of boards! The #1 safety concern is probably to be in a well-ventilated area; my HCl gallon jug smokes when I open it.

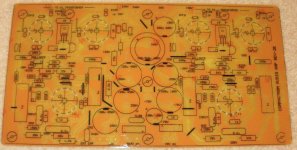

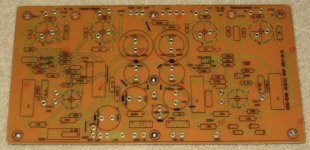

Examples of Toner Transfer PCB

Examples of the toner transfer method for single sided PCB's. I use eyelets where I wish to mount to the back side and solder to the front. Example would be large caps in the back side to allow the PCB's to be mounted where the tube sockets will poke through a top plate.

PCB's for a 6550 based amp, Compactron based amp, ST 70 pcb with 6SN7 and EC99, a couple different headphone amps etc....

Examples of the toner transfer method for single sided PCB's. I use eyelets where I wish to mount to the back side and solder to the front. Example would be large caps in the back side to allow the PCB's to be mounted where the tube sockets will poke through a top plate.

PCB's for a 6550 based amp, Compactron based amp, ST 70 pcb with 6SN7 and EC99, a couple different headphone amps etc....

Attachments

Can anyone recommend a FREE PCB design package that can print onto a Windows 7 printer.

I've just spent all day with FREEPCB creating my boards and the damned software is Print Inhibited.

The aim is to print the copper layers with a laser printer and then transfer the image onto the board using an iron. Therefore no grid marks can be printed on the image.

I've just spent all day with FREEPCB creating my boards and the damned software is Print Inhibited.

The aim is to print the copper layers with a laser printer and then transfer the image onto the board using an iron. Therefore no grid marks can be printed on the image.

ExpressPCB - Free PCB layout software - Low cost circuit boards - Top quality PCB manufacturing

No gerber file, it is setup to order from their shop, but you can print out and use toner transfer.

No gerber file, it is setup to order from their shop, but you can print out and use toner transfer.

Every time I try to print I get a greyed out background with the grid lines on it.

The screen is showing what I want but it wont print the track lines on their own.

i use ExpressPCB and etch my own boards ......

here is what I do .....

1)Design my board in expressPCB.....

2)Take screeshot of board .....

3) import screenshot into MSpaint and invert colors and save as a new image ....

4) Import image into Paint.net (its free , comes with office.net) and add a layer .....

5) now trace out the PCB using the drawing tools provided (in black) ....

6)when finnished tracing the pcb disable the original layer and you will be left with the PCB design , then save the PCB image ....

7) now print out your PCB design and etch your board .....

It is a bit drawn out but I have etched dozzens of boards this way and it works well .....

Cheers

muriatic acid/ hydrogen peroxide etchant

A few days ago I etched a PC board with muriatic acid and 3% hydrogen peroxide in a 1:2 volume ratio. The brand of muriatic acid was klean-strip green (safer). The result was that it took 20 minutes for all of the unprotected copper to dissolve and the board ended up being under-etched in places.

So today I got a second gallon of muriatic acid, this time klean-strip (full-strength) which has 31.5% hydrochloric acid by weight. My second batch of etchant with the full-strength acid removed all of the copper foil from frp with 1 Oz. copper in 6 minutes.

So fellow PCB fabricators (at least here in the U.S. mostly anyway), beware of the Klean-strip GREEN brand of muriatic acid! Looking on the gallon jug of the green muriatic acid, there is no statement as to percent of HCL2.

By the way, my technique for inserting/ removing a PCB from the etchant is to drill two small holes (1/8") at opposite corners of the board and to make a loop of mono-filament (nylon) fishing line through each hole. This also makes it possible to move the board back and forth in the etchant to facilitate the removal of unprotected copper.

-Pete

A few days ago I etched a PC board with muriatic acid and 3% hydrogen peroxide in a 1:2 volume ratio. The brand of muriatic acid was klean-strip green (safer). The result was that it took 20 minutes for all of the unprotected copper to dissolve and the board ended up being under-etched in places.

So today I got a second gallon of muriatic acid, this time klean-strip (full-strength) which has 31.5% hydrochloric acid by weight. My second batch of etchant with the full-strength acid removed all of the copper foil from frp with 1 Oz. copper in 6 minutes.

So fellow PCB fabricators (at least here in the U.S. mostly anyway), beware of the Klean-strip GREEN brand of muriatic acid! Looking on the gallon jug of the green muriatic acid, there is no statement as to percent of HCL2.

By the way, my technique for inserting/ removing a PCB from the etchant is to drill two small holes (1/8") at opposite corners of the board and to make a loop of mono-filament (nylon) fishing line through each hole. This also makes it possible to move the board back and forth in the etchant to facilitate the removal of unprotected copper.

-Pete

I put my boards into one of those snap lock tupperware containers so it is water tight , then I use this little thing made from a walkman motor , couple elastics and a piece of board and a couple hinges that rocks the container back an forth and it usually takes 5 min or less to etch the board .......

a bit of a mc gyver but it works ......

Cheers

a bit of a mc gyver but it works ......

Cheers

Datak works best for me.

I've found that the datak positive boards work best for me. I use multisim to design stuff then lay it out with eagle cad. I print the trace layer onto 3m transparencies with a laser printer and expose the boards for 7 minutes under a sheet of “non UV” treated glass with one of those double circle fluorescent lights, 40 watt I think. Then develop the boards with Datak developer (warmed in microwave to roughly 130F). I then etch with regular old hydrochloric acid and 5% hydrogen peroxide 1:2 ratio (also warmed to 130f or so in the nuker). I do the expose and develop in my closet with a red photo lamp to minimize accidental exposure and heating the solutions just helps them work faster. Next I drill out the holes with my drill press and voila. I've messed up a few but never gave up and now it's very easy and quite fast to put boards together. If interested with this method and have any questions I would be glad to help. Good luck.

I've found that the datak positive boards work best for me. I use multisim to design stuff then lay it out with eagle cad. I print the trace layer onto 3m transparencies with a laser printer and expose the boards for 7 minutes under a sheet of “non UV” treated glass with one of those double circle fluorescent lights, 40 watt I think. Then develop the boards with Datak developer (warmed in microwave to roughly 130F). I then etch with regular old hydrochloric acid and 5% hydrogen peroxide 1:2 ratio (also warmed to 130f or so in the nuker). I do the expose and develop in my closet with a red photo lamp to minimize accidental exposure and heating the solutions just helps them work faster. Next I drill out the holes with my drill press and voila. I've messed up a few but never gave up and now it's very easy and quite fast to put boards together. If interested with this method and have any questions I would be glad to help. Good luck.

muriatic acid/ hydrogen peroxide etchant

Today I etched a board with full strength muriatic acid and 3% hydrogen peroxide. I heated the etching solution with an aquarium heater.

Having etched a fair number of boards with ferric chloride, my impression is that the muriatic acid & hydrogen peroxide solution is not as effective as ferric chloride. Perhaps it would work better if I could find a higher percent hydrogen peroxide.

Also I notice that even when a board isn't being etched, the solution of muriatic acid and hydrogen peroxide is giving off a gas. I suppose this means that a reaction is occurring even without any etching occurring. That would be another minus versus ferric chloride as the ferric chloride isn't reacting when it isn't being used.

If there are any chemists here, it would be interesting to learn what are the chemical reactions going on with the muriatic acid/ hydrogen peroxide solution, with and without copper in the solution. Also, I was wondering, knowing what reactions occur, if there would be a way to rejuvenate the solution.

Regards, Pete

Today I etched a board with full strength muriatic acid and 3% hydrogen peroxide. I heated the etching solution with an aquarium heater.

Having etched a fair number of boards with ferric chloride, my impression is that the muriatic acid & hydrogen peroxide solution is not as effective as ferric chloride. Perhaps it would work better if I could find a higher percent hydrogen peroxide.

Also I notice that even when a board isn't being etched, the solution of muriatic acid and hydrogen peroxide is giving off a gas. I suppose this means that a reaction is occurring even without any etching occurring. That would be another minus versus ferric chloride as the ferric chloride isn't reacting when it isn't being used.

If there are any chemists here, it would be interesting to learn what are the chemical reactions going on with the muriatic acid/ hydrogen peroxide solution, with and without copper in the solution. Also, I was wondering, knowing what reactions occur, if there would be a way to rejuvenate the solution.

Regards, Pete

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- making pc boards