That will be done when I get the other channel done  The first one sounds amazing! At the moment at 1.3 bias, offset is 10mv but I have not tune it yet at full operating temp.

The first one sounds amazing! At the moment at 1.3 bias, offset is 10mv but I have not tune it yet at full operating temp.

I am asking about the technical measurable differences by reducing the bias. Not all of us are lucky enough to have access to good analizing equipment

Best regards,

Regi

I am asking about the technical measurable differences by reducing the bias. Not all of us are lucky enough to have access to good analizing equipment

Best regards,

Regi

Well Regi,

Here's a less technical one for you - the power fets do sound better when the sinks are operating hotter than 50*C (assuming good fet -> sink transfer) so reducing current will reduce fet temp that will reduce sink temp that will change the sound.

So you can keep the temp up (test by finger!) when reducing the current by using smaller heatsink, blocking some of the fins, or hacking off a few cms!

There is a lower power variation in the thread awhile back, for the same purpose that you want - perhaps someone knows the post number?

Here's a less technical one for you - the power fets do sound better when the sinks are operating hotter than 50*C (assuming good fet -> sink transfer) so reducing current will reduce fet temp that will reduce sink temp that will change the sound.

So you can keep the temp up (test by finger!) when reducing the current by using smaller heatsink, blocking some of the fins, or hacking off a few cms!

There is a lower power variation in the thread awhile back, for the same purpose that you want - perhaps someone knows the post number?

Thanks James, but what I am trying to fix is just that, I think my heatsink is too hot. I am waiting to receive in 3 weeks a digital IR thermometer to check it. So if I am not using most of the power, lowering bias should reduce temp.Well Regi,

Here's a less technical one for you - the power fets do sound better when the sinks are operating hotter than 50*C (assuming good fet -> sink transfer) so reducing current will reduce fet temp that will reduce sink temp that will change the sound.

So you can keep the temp up (test by finger!) when reducing the current by using smaller heatsink, blocking some of the fins, or hacking off a few cms!

There is a lower power variation in the thread awhile back, for the same purpose that you want - perhaps someone knows the post number?

Regards,

Regi

That will be done when I get the other channel doneThe first one sounds amazing! At the moment at 1.3 bias, offset is 10mv but I have not tune it yet at full operating temp.

I am asking about the technical measurable differences by reducing the bias. Not all of us are lucky enough to have access to good analizing equipment

Best regards,

Regi

If you only listen at 1 watt then the difference will be minor. I could show you some simulated results, but in the end all that matters is how it sounds while your listening to your favourite album. So that is why I suggested adjusting the bias and listening.

If you really want to see simulations, I will do it though.

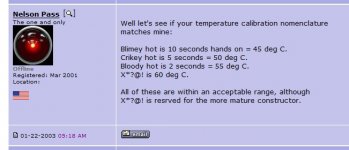

Well, then mine is sitting between 55º and 60º: I don't really know how hot is too hot, I come from the Gainclone world

My F5 is on the 40Cº to 45Cº range on a Hifi2000 4U case (at 20Cº ambient and two hours on).

Running 20A through R11/R12 even for short period of time will blow them out.(If 150 ohm gives a 10A limit, then 100 ohm should give ~15A, 75 ohm ~20A+... )

Are you using car batteries?We tested it until now with it, it´s awesome....

Why do you need all those capacitors when such battery is a big capacitor....And per power rail 80000µF....

I guess they have short circuit current 500A or so.

That would be very interesting if you have them handy (the simulations)If you only listen at 1 watt then the difference will be minor. I could show you some simulated results, but in the end all that matters is how it sounds while your listening to your favourite album. So that is why I suggested adjusting the bias and listening.

If you really want to see simulations, I will do it though.

Thank you, now it is clearer. I will put some pictures as soon as I assemble it, I kinda like it

My F5 is on the 40Cº to 45Cº range on a Hifi2000 4U case (at 20Cº ambient and two hours on).

Then should be similar as mine but it is 3U. Damn, I should have got the4U or even 5U.

modushop.biz

Regards,

Regi

I'm going to drill the holes for the enclosure and heatsinks. At first, I wasn't sure a 6-32 screw was sufficient for the output devices because I didn't want to break off a small screw while trying to get good contact with the heatsink. Now I just noticed a 6-32 screw won't fit through the hole in the Fairchild outputs. I guess I'll have to use smaller screws. Does someone know what size screws to use here?

Thanks

Thanks

I'm going to drill the holes for the enclosure and heatsinks. At first, I wasn't sure a 6-32 screw was sufficient for the output devices because I didn't want to break off a small screw while trying to get good contact with the heatsink. Now I just noticed a 6-32 screw won't fit through the hole in the Fairchild outputs. I guess I'll have to use smaller screws. Does someone know what size screws to use here?

Thanks

I mentioned this to NP about a year ago! I just put them in the drill press. You can always get a metric to fit.

I mentioned this to NP about a year ago! I just put them in the drill press.

You put the output devices in the drill press?

Seems like it's tight on the back side. The screw goes almost all the way through and gets stuck. I tried reaming a little on the back and can get it through but I don't want to compromise the integrity of the transistor case. I'm afraid it will crack from the heat.

The data sheet says the hole is 3.6 + or - .10 . I guess it's in millimeters. So whatever the closest metric size is.

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier