Good afternoon DIYAudio-members,

here are some words and pictures of my latest amplifier in my set.

As i have an active 3-way speaker i need a dedicated tweeter-amplifier. The tweeter itself is a 107 dB field coil compression driver so there is really no need for a power monster. The fact that i could focus on higher frequencies really makes life easier for trannies/sizes.

I used the enclosure and power supply of an earlier/abandonned project: the power supply was produced a very stable 6,3V / 120V / 180V. But the RIAA-part was surpassed by later projects. The power supply was simply to good to dismantle...so now i had a good excuse to re-use those parts.

I'm sure everybody recognizes this.....

As all my other amps are also parafeed this amp is no exception. And pretty straightforward with an input tranny/stepper - tube - capacitor coupling - output tube - parafeed OPT. Normally i like transformer-coupling but at really high frequencies trannies seem to act different. And this is a tweeteramp: capacitor coupling. I took Duelund's normally used as bypass-caps but perfectly admissable for my plans.

What tube to use ? I really really don't know so why not make options as the power supply is over-the-top and there is room for experimantation (power reserve). So the amplifier is fitted with very handy multiple pin octal sockets and with the aid of very large convertor sockets (with built in compensation resistors / kathode resistors / etc) i have the following options:

For input tube: AC100 / Ec / 4P1L

For output tube: ED111 / 12B4 / ML6 / 6S4A

All combinations allowed.

Currently i'm running in this tweeteramp (very nice first impressions with the combination 4P1L - ED111) but i have to find out what is the nicest combination with all options of diaphragms in the tweeter.

Regards,

Reinout

here are some words and pictures of my latest amplifier in my set.

As i have an active 3-way speaker i need a dedicated tweeter-amplifier. The tweeter itself is a 107 dB field coil compression driver so there is really no need for a power monster. The fact that i could focus on higher frequencies really makes life easier for trannies/sizes.

I used the enclosure and power supply of an earlier/abandonned project: the power supply was produced a very stable 6,3V / 120V / 180V. But the RIAA-part was surpassed by later projects. The power supply was simply to good to dismantle...so now i had a good excuse to re-use those parts.

I'm sure everybody recognizes this.....

As all my other amps are also parafeed this amp is no exception. And pretty straightforward with an input tranny/stepper - tube - capacitor coupling - output tube - parafeed OPT. Normally i like transformer-coupling but at really high frequencies trannies seem to act different. And this is a tweeteramp: capacitor coupling. I took Duelund's normally used as bypass-caps but perfectly admissable for my plans.

What tube to use ? I really really don't know so why not make options as the power supply is over-the-top and there is room for experimantation (power reserve). So the amplifier is fitted with very handy multiple pin octal sockets and with the aid of very large convertor sockets (with built in compensation resistors / kathode resistors / etc) i have the following options:

For input tube: AC100 / Ec / 4P1L

For output tube: ED111 / 12B4 / ML6 / 6S4A

All combinations allowed.

Currently i'm running in this tweeteramp (very nice first impressions with the combination 4P1L - ED111) but i have to find out what is the nicest combination with all options of diaphragms in the tweeter.

Regards,

Reinout

Attachments

-

1 spare enclosures.jpg468.2 KB · Views: 421

1 spare enclosures.jpg468.2 KB · Views: 421 -

10 Ec option.jpg262 KB · Views: 147

10 Ec option.jpg262 KB · Views: 147 -

9 ED111.JPG388.8 KB · Views: 143

9 ED111.JPG388.8 KB · Views: 143 -

8 convertor sockets detail.jpg162.1 KB · Views: 126

8 convertor sockets detail.jpg162.1 KB · Views: 126 -

7 convertor socket options.jpg187.7 KB · Views: 132

7 convertor socket options.jpg187.7 KB · Views: 132 -

6 convertor sockets.jpg258.9 KB · Views: 151

6 convertor sockets.jpg258.9 KB · Views: 151 -

5 tube options.JPG430.6 KB · Views: 418

5 tube options.JPG430.6 KB · Views: 418 -

4 trannies and coils.JPG840.9 KB · Views: 453

4 trannies and coils.JPG840.9 KB · Views: 453 -

3 metalwork.....JPG314.8 KB · Views: 413

3 metalwork.....JPG314.8 KB · Views: 413 -

2 spare supplies.jpg268.1 KB · Views: 415

2 spare supplies.jpg268.1 KB · Views: 415

pictures follow up

text above....

Example 1: AC100 + ML6 tube choie

Example 2: EC + ED111 tube choice

text above....

Example 1: AC100 + ML6 tube choie

Example 2: EC + ED111 tube choice

Attachments

-

19 example 2.JPG642.2 KB · Views: 166

19 example 2.JPG642.2 KB · Views: 166 -

18 example 1.JPG658.5 KB · Views: 163

18 example 1.JPG658.5 KB · Views: 163 -

17 tweeter amp all options.JPG624.9 KB · Views: 153

17 tweeter amp all options.JPG624.9 KB · Views: 153 -

16 tweeter amp open.JPG599.5 KB · Views: 159

16 tweeter amp open.JPG599.5 KB · Views: 159 -

15 tweeter amp open complete.JPG692.3 KB · Views: 174

15 tweeter amp open complete.JPG692.3 KB · Views: 174 -

14 work in progress 4.jpg332 KB · Views: 171

14 work in progress 4.jpg332 KB · Views: 171 -

13 work in progress 3.jpg277.4 KB · Views: 168

13 work in progress 3.jpg277.4 KB · Views: 168 -

12 work in progress 2.jpg346.1 KB · Views: 175

12 work in progress 2.jpg346.1 KB · Views: 175 -

11 work in progress 1.jpg267.3 KB · Views: 169

11 work in progress 1.jpg267.3 KB · Views: 169

follow up

Details of some nice components:

- the Duelund caps as coupling capacitor (in reality the 0.01 uF is somewhat too large.....);

- the loctal sockets. Normally these loctals have very shitty sockets but luckily i found Luciano (Jakeband) in Italy who makes marvelous stuff from teflon. Serious positive grip ! Now i can really use that 4P1L and understand why that tube is so much loved.....

Link to Jakeband-sockets: jakeband

Tweeter amp on the bottom shelf generating about a single Watt....

Regards,

Reinout

Details of some nice components:

- the Duelund caps as coupling capacitor (in reality the 0.01 uF is somewhat too large.....);

- the loctal sockets. Normally these loctals have very shitty sockets but luckily i found Luciano (Jakeband) in Italy who makes marvelous stuff from teflon. Serious positive grip ! Now i can really use that 4P1L and understand why that tube is so much loved.....

Link to Jakeband-sockets: jakeband

Tweeter amp on the bottom shelf generating about a single Watt....

Regards,

Reinout

Attachments

Last edited:

Good morning Astouffer,

thank you....i consider that a compliment.

It's a 400 kgs affair; air stabilised platform; air bearing platter; external secondary axle; etc.

I've made a photo serie + text on this forum (Caeles-special; an air-bearing turntable ). It's my primary source.

Picture included. You still see the tweeteramp below right.

The turntable is partially blocking the view of the motor, the battery power supply of the motor and the vacuum pump for socking the vinyl to the platter.

The speaker is partially blocking the view on the air filters.

Regards,

Reinout

thank you....i consider that a compliment.

It's a 400 kgs affair; air stabilised platform; air bearing platter; external secondary axle; etc.

I've made a photo serie + text on this forum (Caeles-special; an air-bearing turntable ). It's my primary source.

Picture included. You still see the tweeteramp below right.

The turntable is partially blocking the view of the motor, the battery power supply of the motor and the vacuum pump for socking the vinyl to the platter.

The speaker is partially blocking the view on the air filters.

Regards,

Reinout

Attachments

Hi Reinout!

Are the transformers with the key as reference the choke load and OPT? Could be, if these are wound to play from 1khz upwards only. Can you tell a bit more?

Also, what (active?) Xover topology are you using?

Thanks! Erik

Are the transformers with the key as reference the choke load and OPT? Could be, if these are wound to play from 1khz upwards only. Can you tell a bit more?

Also, what (active?) Xover topology are you using?

Thanks! Erik

Hey Reinout, it looks like those plates were laser cut? Could you tell us where you had this done and if it was somewhat affordable? (for example how much did such that top plate cost you?) Living in an apartment limits my ability to do metal work so having an affordable laser cutting service nearby would be awesome 🙂

Good evening wg_ski,

you could be right but i simply need this over-the-top (but highly effective isolation) as i live 50 meters next to a very busy rail line. Every 4 minutes a train passes and although i don't hear the train anymore (simply because you're accustomed to the sound) the vibrations are serious enough to derail a normal turntable/cartridge.

With my contraption it is really isolated.

Last push to silence were 3 oil baths below the subframe taking care of all rest energy floating around which is simply smothered.

Regards,

Reinout

(and now back on topic)

you could be right but i simply need this over-the-top (but highly effective isolation) as i live 50 meters next to a very busy rail line. Every 4 minutes a train passes and although i don't hear the train anymore (simply because you're accustomed to the sound) the vibrations are serious enough to derail a normal turntable/cartridge.

With my contraption it is really isolated.

Last push to silence were 3 oil baths below the subframe taking care of all rest energy floating around which is simply smothered.

Regards,

Reinout

(and now back on topic)

Attachments

Good evening Erik,

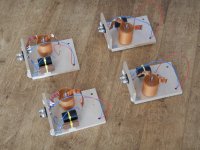

those trannies/coils are indeed the used ones in this tweeteramp.

And the larger ones (still small compared to "standard" sizes; see car-keys as reference) are the parafeedcoils ! The smaller are the OPTs.

No saturating DC as this is a parafeed-amp and from 1 kHz upwards....so no bass-energy. So i could use funny material from old Siemens HF-equipment.

The opt is nicely encased in a mumetal box.

The laminations of the coil/OPt were ridicilous thin. I think 0,05 mm but it could be much less but have no way to measure that.

Just check the clip to see the thickness of a single lamination.

My XO is in 2 parts:

- active dividing around 500 Hz (using a PAP-C1). This Nelson Pass design gives me the opportunity to nicely smooth in/out the woofers and sparing a massive bass-coil. I have experience with serious bass-cores but even the best are not as snappy as the less-is-more FET-based Pass-design (but kicked out the standard power supply immediately....)

- passive dividing around 4250 Hz. 2nd order so not much stuff needed; invested in quality (Mundorf VLCU coils are really nice ; and i prefer Mundorf SilverOils over SilverGoldOils but thats just taste)

Regards, Reinout

those trannies/coils are indeed the used ones in this tweeteramp.

And the larger ones (still small compared to "standard" sizes; see car-keys as reference) are the parafeedcoils ! The smaller are the OPTs.

No saturating DC as this is a parafeed-amp and from 1 kHz upwards....so no bass-energy. So i could use funny material from old Siemens HF-equipment.

The opt is nicely encased in a mumetal box.

The laminations of the coil/OPt were ridicilous thin. I think 0,05 mm but it could be much less but have no way to measure that.

Just check the clip to see the thickness of a single lamination.

My XO is in 2 parts:

- active dividing around 500 Hz (using a PAP-C1). This Nelson Pass design gives me the opportunity to nicely smooth in/out the woofers and sparing a massive bass-coil. I have experience with serious bass-cores but even the best are not as snappy as the less-is-more FET-based Pass-design (but kicked out the standard power supply immediately....)

- passive dividing around 4250 Hz. 2nd order so not much stuff needed; invested in quality (Mundorf VLCU coils are really nice ; and i prefer Mundorf SilverOils over SilverGoldOils but thats just taste)

Regards, Reinout

Attachments

Good evening Gideon1990,

these stainless steel top- and innerplates are not lasercut but waterjet-cut.

Numerous waterjet-cutters everywhere. The price of the actual cutting and material is less then € 100 for both plates.

BUT.....

I got a collegue that translates my needs in a CAD-file. If you hand over just a drawing this means the metalwork-firm has to spent time in computerwork. And THAT's expensive; certainly more then the cutting itself.

So: make your own CAD-file and ask around for prices.

In the end i have these made in Germany (i live very close to the border; 30 minutes by speed pedelec to that metalwork shop)

Regards,

Reinout

these stainless steel top- and innerplates are not lasercut but waterjet-cut.

Numerous waterjet-cutters everywhere. The price of the actual cutting and material is less then € 100 for both plates.

BUT.....

I got a collegue that translates my needs in a CAD-file. If you hand over just a drawing this means the metalwork-firm has to spent time in computerwork. And THAT's expensive; certainly more then the cutting itself.

So: make your own CAD-file and ask around for prices.

In the end i have these made in Germany (i live very close to the border; 30 minutes by speed pedelec to that metalwork shop)

Regards,

Reinout

Attachments

Last edited:

..., it looks like those plates were laser cut? Could you tell us where you had this done and if it was somewhat affordable? (for example how much did such that top plate cost you?) Living in an apartment limits my ability to do metal work so having an affordable laser cutting service nearby would be awesome ...

I had some 3mm aluminium plates laser cut recently and it was surprisingly reasonable. I used these guys ...

Plåtprecision.se

... since I am based in Stockholm, but I think it is a general service in this automated world.

I generated a drawing with exact measurements using a drawing package - Open Office was fine. They charged me around €30 to convert the drawing into a standard language for their machines. That is a one off cost for each design, so definitely an oportunity there when we build standard PCB-based solutions from DiyAudio. I think if you are able to generate CAD drawings (DWG files?) then it is cheaper.

Then I think it was just €15 per 270mm square 3mm plate, laser cut.

Best to contact your local aluminium plate specialist and see what they can offer. The guy who helped me explained that the machines work on their own overnight, so the costs are mostly just the machine programming.

Last edited:

Sub 100 euro for BOTH plates is pretty amazing. I'll look into it and I have just enough cad drawing skills to design a panel like that since we have a (not metal) lasercutter at work.

OldHector, that sounds pretty great too. Now I'm just wondering, 270 sq mm sounds awfully specific, do you know where that number comes from?

OldHector, that sounds pretty great too. Now I'm just wondering, 270 sq mm sounds awfully specific, do you know where that number comes from?

I had 2 old IKEA beech wall units that were basically boxes, 270mm x 270mm. They were sufficuiently deep to be cut in half, so I ended up with 4 different height amplifier bases.

Unfortunately I am not home, and only have a picture of the one I hacked myself using an IKEA tap hole cutter.

Unfortunately I am not home, and only have a picture of the one I hacked myself using an IKEA tap hole cutter.

Attachments

Very nice amp and solidly built (I think even a bit over-engineered 😉), but I would rather build a full range amp with full range opt's, so it can be used for other purposes, may the need arise. It may be somewhat more expensive to build up front, though. I don't think a smaller opt will change the quality of the treble very much, when using quality transformers.

Hi Horneytube,

if you have the opportunity to make specific trannies/amps for specific frequency bands from scratch that is a huge benefit as you can optimise without having the need to take care of unwanted demands of not needed specifications.

That 0.7 W tweeteramp measures straight within 1 dB from 1 kHz to 160 kHz. That is (in my humble opinion) quite impressive for tube gear. If i would have started with a full range amp these numbers wouldn't be achievable.

Of course full range amps are extremely versatile. Exactly the reason why i have them also (and use them as "mid-amps"). But on the frequency extremes it gives you more options to use funny parts / topologies / etc.

So for this tweeter amp i looked seriously into HF-building and applied semi-rigid cabling with surprising results.

Regards,

Reinout

if you have the opportunity to make specific trannies/amps for specific frequency bands from scratch that is a huge benefit as you can optimise without having the need to take care of unwanted demands of not needed specifications.

That 0.7 W tweeteramp measures straight within 1 dB from 1 kHz to 160 kHz. That is (in my humble opinion) quite impressive for tube gear. If i would have started with a full range amp these numbers wouldn't be achievable.

Of course full range amps are extremely versatile. Exactly the reason why i have them also (and use them as "mid-amps"). But on the frequency extremes it gives you more options to use funny parts / topologies / etc.

So for this tweeter amp i looked seriously into HF-building and applied semi-rigid cabling with surprising results.

Regards,

Reinout

Hi Horneytube,

if you have the opportunity to make specific trannies/amps for specific frequency bands from scratch that is a huge benefit as you can optimise without having the need to take care of unwanted demands of not needed specifications.

From an engineering point of view, I think you are right but how will a bandwith up to 160khz benefits music reproduction as we humans perceive it? Wouldn't those benefits be possible without such bandwith? Up to 40khz should do, or I am mistaken? Isn't that high bandwith in itself a "not needed specification"? You might need a radio license 😉

I recon that the amp itself is an amazing build and if it is the goal to build a 160khz amp, then that is perfectly o.k. with me. I see no correlation of this technological feat with music reproduction however, as my hearing is not that good, but your milage may vary.

That 0.7 W tweeteramp measures straight within 1 dB from 1 kHz to 160 kHz. That is (in my humble opinion) quite impressive for tube gear. If i would have started with a full range amp these numbers wouldn't be achievable.

Yes, impressive it is! I do have a monoblock tube amp that is fullrange and flat up to 100khz but I agree that is not common. OTL can do it, and my amp that has some similarities with OTL but uses a big auto-transformer.

Of course full range amps are extremely versatile. Exactly the reason why i have them also (and use them as "mid-amps"). But on the frequency extremes it gives you more options to use funny parts / topologies / etc.

So for this tweeter amp i looked seriously into HF-building and applied semi-rigid cabling with surprising results.

Studying, designing and building must have been a lot of fun, and I like out of the box thinking, too. I also use a tweeter tube amp, but fullrange design. I think that it benefits soundwise from not getting low frequencies, as it may translate into less distiortion. Another advantage may be that a tube amp is safer, because it cannot put out dc-currents to the fragile tweeter. Thanks for sharing 🙂

~~Miguel~~

Good evening Horneydude,

what can i say.....shocked / perplexed ?

Just as you're trying to push boundaries with your 3D speaker design i'm trying to explore the maximum in/with amplifiers (and K-tubes to be complete); the 160 kHz figure was just an example and not a design goal but a result from proper engineering/execution given the possibility of a smaller frequency band (no bass....which opens up higher frequency possibilities).

Your reply is a perfect example how to demotivate any sharing on a DIY-forum.

I'm glad that you have your set perfect; please let me struggle at my level as obviously i can not touch the level you're working on.

Regards, Reinout

what can i say.....shocked / perplexed ?

Just as you're trying to push boundaries with your 3D speaker design i'm trying to explore the maximum in/with amplifiers (and K-tubes to be complete); the 160 kHz figure was just an example and not a design goal but a result from proper engineering/execution given the possibility of a smaller frequency band (no bass....which opens up higher frequency possibilities).

Your reply is a perfect example how to demotivate any sharing on a DIY-forum.

I'm glad that you have your set perfect; please let me struggle at my level as obviously i can not touch the level you're working on.

Regards, Reinout

Last edited:

Good evening Reinout,

I think we have a language problem here; as English is not my native language, I must have translated my thoughts in such a way, that you seem to be offended by my questions and remarks. I am sorry for that.

I have no intentions to disqualify your quest for pushing the limits. Without people like you there would be no progress. The bandwith you speak of is indeed the result of using a smaller OPT and/or condensators, not a goal as such -so that is understood now. Nevertheless, you advertised your amp as having a flat FR to 160khz, so I imagined that that matters to you.

In that respect, I would like to hear from you how your tweeter amp translates to a better reproduction of music than other solutions. I (and presumably others) am looking forward to some measurements of your K-tube and amplifier system. I know measurements do not tell everything, especially not about musicality, but it may back up your statements.

Meanwhile, I certainly do not have a perfect system (if one exists) and I do not claim that. My 3d printed horns do have some flaws (that are acceptable to me). I do have a "concept" that I try to perfect and eventually to share. Other people may not like it and that is o.k. if they tell me why not.

I do not aspire to push engineering boundaries like you but I appreciate people who do. I do aspire to have a system that sounds musical to me, and that is a subjective matter. So the most interesting thing I would like to hear from you, is how it sounds relative to other amps you may have tried.

You make your choices and I do mine. We may have different intentions and goals with our hobby and that is also fine. I know we are both music lovers, and for me that is the point of being an audiophile.

So your sharing is inspiring, it is just not the case that everyone should just cheer and ask no questions, that is not how it works imo.

Regards,

~~Miguel~~

I think we have a language problem here; as English is not my native language, I must have translated my thoughts in such a way, that you seem to be offended by my questions and remarks. I am sorry for that.

I have no intentions to disqualify your quest for pushing the limits. Without people like you there would be no progress. The bandwith you speak of is indeed the result of using a smaller OPT and/or condensators, not a goal as such -so that is understood now. Nevertheless, you advertised your amp as having a flat FR to 160khz, so I imagined that that matters to you.

In that respect, I would like to hear from you how your tweeter amp translates to a better reproduction of music than other solutions. I (and presumably others) am looking forward to some measurements of your K-tube and amplifier system. I know measurements do not tell everything, especially not about musicality, but it may back up your statements.

Meanwhile, I certainly do not have a perfect system (if one exists) and I do not claim that. My 3d printed horns do have some flaws (that are acceptable to me). I do have a "concept" that I try to perfect and eventually to share. Other people may not like it and that is o.k. if they tell me why not.

I do not aspire to push engineering boundaries like you but I appreciate people who do. I do aspire to have a system that sounds musical to me, and that is a subjective matter. So the most interesting thing I would like to hear from you, is how it sounds relative to other amps you may have tried.

You make your choices and I do mine. We may have different intentions and goals with our hobby and that is also fine. I know we are both music lovers, and for me that is the point of being an audiophile.

So your sharing is inspiring, it is just not the case that everyone should just cheer and ask no questions, that is not how it works imo.

Regards,

~~Miguel~~

- Home

- Amplifiers

- Tubes / Valves

- Tweeter amplifier (1 kHz upwards...)