I am planning to have some volume knobs made for my own. Still looking for ideas. Just wonder, in your opinion, which manufacturer has the nicest volume knob on their amps? Images are much welcomed.

My favorites so far are the ones from Daniel Hertz and Pass Labs. D'Agostino has a very unique one on his preamp but it is too complicated to make...

My favorites so far are the ones from Daniel Hertz and Pass Labs. D'Agostino has a very unique one on his preamp but it is too complicated to make...

An externally hosted image should be here but it was not working when we last tested it.

I am planning to have some volume knobs made for my own. Still looking for ideas.

Consider the function before form. It should be round to be consistent in handling, regardless of position.

Diameter should be large enough to be comfortable to turn, and to allow precise adjustment.

Plenty of space around it for your hand. An easily visible position mark, but no glaring LEDs.

Locate it on the right side, since most people are right handed.

Last edited:

Yes they are! I own several different types collected over the years. The IV-S is my fave.Nagra is pretty sweet,

Attachments

Hah, those "glaring" pictures are a function of digital cameras. In real life they are much more demure....but no glaring LEDs.

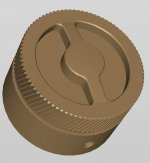

Yes, of course I still stick with cylinder shape, just looking for some unique front cutout. LED insert is cool, thought about it before. Below is a 3D render of what I am planning. Either copper or brass, still trying out to figure which will match the amp.

Attachments

Either copper or brass, still trying out to figure which will match the amp.

Nice, you'll need to have a protective clear coating to prevent corrosion. Consider two set screws

to reduce loosening over time.

Yes, a protective layer will be applied. I had a stainless steel one and really loved its weight and feel, would consider making champagne color. 2 sets of screw is a great idea, thanks for the suggestion.

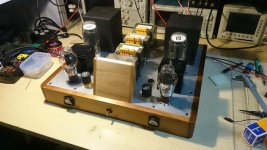

Below is the amp I am working on, there will be another copper plate on top of the current aluminum one. Hopefully the knob will be a nice touch for the amp.

Below is the amp I am working on, there will be another copper plate on top of the current aluminum one. Hopefully the knob will be a nice touch for the amp.

Attachments

I had a stainless steel one and really loved its weight and feel, would consider making champagne color.

2 sets of screw is a great idea, thanks for the suggestion.

Nice work. I'd go with stainless steel, that would work out the best. Most larger knobs do have two set screws,

about 90 degrees apart. The extra torque hitting the stops with the larger diameter knob tends to

cause loosening with only one set screw.

Yes, of course I still stick with cylinder shape, just looking for some unique front cutout. LED insert is cool, thought about it before. Below is a 3D render of what I am planning. Either copper or brass, still trying out to figure which will match the amp.

Rol, who will you get to make your knobs and what sort of price are you expecting to pay?

Rol, who will you get to make your knobs and what sort of price are you expecting to pay?

I have a lot of CNC shops local, will send out the design to get the price quote. Probably won't cheap though because I only ask for small quantity.

@Calvin very nicely done work there!

My uncle told be two things about getting good prices from suppliers:I have a lot of CNC shops local, will send out the design to get the price quote. Probably won't cheap though because I only ask for small quantity.

1] No time constraints about when they do the job. That way they can do it near the end of a day when it's too late to start a big job.

2] Tell them in advance that you will pay with cash, when you pick up the project.

It is amazing what a little investment in building such a relationship can yield - in some cases no more than a 24 pack on a warm Friday afternoon to be shared with the shop crew, but something you might want to keep in mind with "cash"/ end of shift side jobs can be reliability - there may only be one or two machine operators willing/ able to consistently meet the quality of detail and finish that you're looking for - especially after partial consumption of said prepayment.

Very nice and modern indeed!Hi,

still like mine ;-)

Featuring preloaded double ball bearings, it turns smooth like silk.

Integrated touch sensor and display, so nothing else needed on the front plate.

jauu

Calvin

Yes, of course I still stick with cylinder shape, just looking for some unique front cutout. LED insert is cool, thought about it before. Below is a 3D render of what I am planning. Either copper or brass, still trying out to figure which will match the amp.

FWIW, brass would be much easier to machine, not to mention that the brass bar stock would likely be much more easily available and less expensive. Copper is 'gummy' (for lack of a better word) in my limited experience trying to hack some heat spreader plates out of copper on an old Bridgeport mill years ago...

-Pat

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Member Areas

- The Lounge

- Which company has the best looking volume knob on their amps?