Hi all

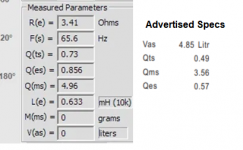

I purchased a Tang Band W5-1138SMF subwoofer for a project of mine. I proceeded to measure the free air parameters with DATS V3 and I got completely different results from the specs, especially the Fs that registered at 65HZ instead of the advertised in the specs 45HZ. I attach a picture of the measured free air parameters in DATS vs the advertised ones by Tang Band.

Since the speaker was brand new I proceeded to give it a reasonable burn in period and tried again to measure. Again the measurements did not improve with Fs being reported close to 63HZ now, but nowhere near the advertised 45HZ.

For peace of mind I went on and purchased a second similar unit from a different supplier, and guess what! The second brand new speaker also had similar bad results when tested in DATS V3. My set up for DATS V3 is working perfectly since all other speakers I have tested come very close to advertised specs.

So based on my experience on buying two different similar speakers from different suppliers and both measuring bad either (a) Tang Band has very bad quality control, or (b) it lies on the advertised specs to push sales, or (c) it sells at discount the speakers that do not pass quality control to dealers which subsequently sell them to innocent consumers without a reference that they are buying a defective product.

I do not care if (a), (b) or (c) is true, or all of the three, but in any case Tang Band is not a brand I will ever trust again as a consumer. I plan to post a video on youtube to expose their shortcomings as a brand.

I purchased a Tang Band W5-1138SMF subwoofer for a project of mine. I proceeded to measure the free air parameters with DATS V3 and I got completely different results from the specs, especially the Fs that registered at 65HZ instead of the advertised in the specs 45HZ. I attach a picture of the measured free air parameters in DATS vs the advertised ones by Tang Band.

Since the speaker was brand new I proceeded to give it a reasonable burn in period and tried again to measure. Again the measurements did not improve with Fs being reported close to 63HZ now, but nowhere near the advertised 45HZ.

For peace of mind I went on and purchased a second similar unit from a different supplier, and guess what! The second brand new speaker also had similar bad results when tested in DATS V3. My set up for DATS V3 is working perfectly since all other speakers I have tested come very close to advertised specs.

So based on my experience on buying two different similar speakers from different suppliers and both measuring bad either (a) Tang Band has very bad quality control, or (b) it lies on the advertised specs to push sales, or (c) it sells at discount the speakers that do not pass quality control to dealers which subsequently sell them to innocent consumers without a reference that they are buying a defective product.

I do not care if (a), (b) or (c) is true, or all of the three, but in any case Tang Band is not a brand I will ever trust again as a consumer. I plan to post a video on youtube to expose their shortcomings as a brand.

Attachments

Did your "reasonable burn in period" include reaching and exceeding the 9.25mm Xmax (18.5mm peak to peak, about 3/4 inch), and if so, for how long? If not, the suspension will still be overly stiff, and Fs will be higher than the factory specification, especially at low drive levels.I proceeded to measure the free air parameters with DATS V3 and I got completely different results from the specs, especially the Fs that registered at 65HZ instead of the advertised in the specs 45HZ.

Since the speaker was brand new I proceeded to give it a reasonable burn in period and tried again to measure. Again the measurements did not improve with Fs being reported close to 63HZ now, but nowhere near the advertised 45HZ.

Were the drivers pre-conditioned just prior to your tests?

What was the voltage level for your tests?

Last edited:

What drive level do you use? What is the air temperature? What did you do to burn it in?

I measured fs = 50 Hz on my W5-1138sm (specced at 45 Hz).

DATS V3 takes care of all these settings, drive level etc, it automatically test the free air parameters and it has done this in the past very successfully with known good speakers. For burn in I played continuously for72 hours jazz music with the driver connected to the subwoofer output of an arylic 2.1 amp board with a low pass filter at 150HZ.

?What is the air temperature?

I ask because rubber surrounds become stiff at low temperatures.

If you do not know the drive level, you could measure it.DATS V3 takes care of all these settings, drive level etc

Fair point.it has done this in the past very successfully with known good speakers

What excursion did the woofer reach during burn in and how often?For burn in I played continuously for72 hours jazz music with the driver connected to the subwoofer output of an arylic 2.1 amp board with a low pass filter at 150HZ.

A quick and safe way to burn in a woofer, is by applying a sine wave at fs. The cones reaches a high peak excursion easily and many times per second and there is little chance of overheating the coil.

Last edited:

This is true if the woofer is driven open air, but in an enclosure, Pe may be exceeded at Fs before Xmax is reached, the driver could "burn out" before being "broken in".A quick and safe way to burn in a woofer, is by applying a sine wave at fs. The cones reaches a high peak excursion easily and many times per second and there is little chance of overheating the coil.

One can also safely push the cone past Xmax to Xlim "by hand" using even finger pressure to break in the suspension with no danger of burning the voice coil.

Last edited:

DATS V3 takes care of all these settings, drive level etc, it automatically test the free air parameters and it has done this in the past very successfully with known good speakers.

Actually it doesn't. Or rather it does and it doesn't. DATS measures at a low voltage drive level (since T/S parameters are technically small signal), but if a manufacturer has measured at a higher voltage drive, which many do, you will often get variations. It's possible in V3 to increase the drive level a little; go into the 'scope mode and in the Z sweep amplitude, increase to the maximum of 11.4dBu. Any T/S measures will now be at that signal level.

For burn in I played continuously for72 hours jazz music with the driver connected to the subwoofer output of an arylic 2.1 amp board with a low pass filter at 150HZ.

Not really enough, especially with drivers that have a large linear travel & relatively substantial suspension. I would suggest (in free air) you run a programme of test tones / sinewaves, steadily decreasing in frequency of say, 40Hz, 35Hz, 30Hz, 25Hz, 20Hz, 15Hz, 10Hz etc. At least 10 minutes of each, pushing to just below the limit of mechanical travel. Wait for the coil to return to room temperature & remeasure. You'll likely find Fs drops a good few Hz. Note also the point made above about ambinet temperature and pressure: you can get some variations from this. Not vast, but some.

I've had similar variations with units from another well-known and well-regarded manufacturer who shall remain nameless as it is work I was doing for my employer, and I'm obliged to be diplomatic on such things for commercial considerations. So what you are finding with these is unfortunately far from unique or exclusive. I wish it was.

I proceeded to measure the free air parameters with DATS V3 and I got completely different results from the specs, especially the Fs that registered at 65HZ instead of the advertised in the specs 45HZ.

Fully expected. DATS3 does not test the driver under the same conditions so given that the numbers we refer to as T/S are scalars collapsed from a curve, typical factory testing, in my experience, being a better starting point.

Further (according to the authour), DATS3 “guesses” th eparameters from the impedance curves and does not directly measure them.

A 3rd issue is how tight the manufacturing consistency is.

Having measured 1,000s of drivers (for matching/testing purposes, as i always start out with factory data if available), very consistent makers might hit less than +/- 10% deviation in specs. Others can be far worse. I have measured some drivers so far apart as to be considered different drivers. Expected with really old drivers, sad when you see it in brand new drivers. I haven’t measured nearly as many TB as others, but their consistency was not the best.

To get the factory data, a sample set of driver sfrom a production run (say 50-100), measure them all, then average the data.

TB drivers also seems to be a moving target, diy not their largest set of customers, diy drivers are often made from left-over parts runs (or extended parts runs).

dave

Adding to what TBTL said, the weather conditions you measure at directly affect the numbers you get. Mostly temperature and air pressure, but humidity and other factors can also stick their head in.

I only ever used measurements from the same session to match drivers.

dave

I only ever used measurements from the same session to match drivers.

dave

Compare the corresponding calculated EM parameters (BL, Cms, Mms, etc.) with the published ones. The differences there might give more insight into what's causing the difference, though in this case the difference in Fs suggests that the suspension is way too tight. And yes, while the method of measuring the drivers will result in somewhat different results, the results should not be THAT different.

When new i get a higher Qes and Fs on the w5. I dont even recall the ‘new’ Vas or think ive measured it. But in the well used versions the Fs is not far off and everything else is within the 10-15% mark. Better yet, the sims dont even barely show a sliver of change in factory vs measured and broke in. I use funky tapped horn shapes and expanding TL varieties.

Broke in is well over 8 hours below Fs and at an input that provides an excursion near xmax. That can be ‘40 hours’ in one driver i have(not the tangband).

Broke in is well over 8 hours below Fs and at an input that provides an excursion near xmax. That can be ‘40 hours’ in one driver i have(not the tangband).

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Tang Band W5-1138SMF 5-1/4" Subwoofer - Specs all over the place?