Hey all after many many years of wanting to, and then finally finding two more drivers i am now on my way to making twin subs, each containing two 12 inch peerless drivers..sealed boxes

The original duel 12 inch sub i build many years ago has been great but its a bit bulky looking and want something a bit sleeker. so going with curved sides this time.

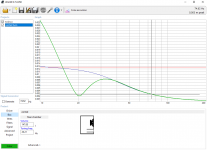

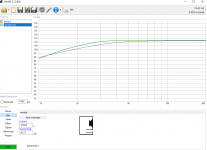

So the new boxes will be taller to match the floor standers, a bit wider but shorter.... It will still increase volume from 126L to 147L and change the qtc from 0.7 to 0.67 as modeled in WIn isd.. win isd models show the drivers will reach xmax easier... But I will still be using the existing amp so lesss power??

Amp is a dayton 1000w sub amp, older one.

2 x 4 ohm in series amp sees 500w 8 ohms (speakers are 150w x 2)

add another box in parallel amp sees 4 ohms 900w?? (speakers now 150 x 4)

Will this work ok...

any ideas or suggestions are welcome.

The original duel 12 inch sub i build many years ago has been great but its a bit bulky looking and want something a bit sleeker. so going with curved sides this time.

So the new boxes will be taller to match the floor standers, a bit wider but shorter.... It will still increase volume from 126L to 147L and change the qtc from 0.7 to 0.67 as modeled in WIn isd.. win isd models show the drivers will reach xmax easier... But I will still be using the existing amp so lesss power??

Amp is a dayton 1000w sub amp, older one.

2 x 4 ohm in series amp sees 500w 8 ohms (speakers are 150w x 2)

add another box in parallel amp sees 4 ohms 900w?? (speakers now 150 x 4)

Will this work ok...

any ideas or suggestions are welcome.

Last edited:

sealed box, older drivers 830952, I have 4 so going to use them

http://www.tymphany.com/wordpress/w...less-discontinued-transducer-model-830952.pdf

http://www.tymphany.com/wordpress/w...less-discontinued-transducer-model-830952.pdf

Last edited:

arr thanks i did the modeling myself last night. same everything, at 170W signal input

So some questions about the results

Vented gives me +5db from 30 to 20

vented the drivers reach xmax ~ 15hz at 170w ( sealed its safe to 10)

I also compared at 50w, vented is safe to 10hz and still produces spl around 100db, whiled sealed at 50w spl is way down around 50db

No Surprise sealed requires more power.

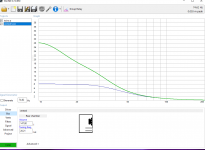

With the group delay, does it show that the lower frequencies take longer to be produced with the vented enclosure?? So is this why vented boxes give that boomier sound, where as a sealed box sounds tighter?

maybe i am missing something, yes there is a 5db gain in the sweet spot, but not not being sold on going vented, I might just add another layer of mdf internally to the front and back panels, plus poly fill to bring the volume down...

Also added a pic of the current sealed 126L box..

So some questions about the results

Vented gives me +5db from 30 to 20

vented the drivers reach xmax ~ 15hz at 170w ( sealed its safe to 10)

I also compared at 50w, vented is safe to 10hz and still produces spl around 100db, whiled sealed at 50w spl is way down around 50db

No Surprise sealed requires more power.

With the group delay, does it show that the lower frequencies take longer to be produced with the vented enclosure?? So is this why vented boxes give that boomier sound, where as a sealed box sounds tighter?

maybe i am missing something, yes there is a 5db gain in the sweet spot, but not not being sold on going vented, I might just add another layer of mdf internally to the front and back panels, plus poly fill to bring the volume down...

Also added a pic of the current sealed 126L box..

Attachments

Last edited:

Your current sub looks great, love it.

Vented enclosures do have more group delay in the lower frequencies, but group delay is less easily perceived (audible) the lower the frequency. Where typical vented subs are producing the highest group delay is in frequency bands where the delay is inaudible. I'd argue that boominess of vented subs is a myth - vented subs have much greater output at frequencies that typically then interact with room modes and cause ringing - not actually caused by the sub itself, by by the room - If you used multiple sealed subs and boosted at the low frequencies to compensate for their rollof eg to achieve a flat response similar to vented, the boominess would also exist.

To summarise, boominess is not caused by the sub, its caused by the room.

Car audio SPL type subwoofer designs also have led to this myth of vented being boomy, because they tune for maximum output at the tuning frequency (say 30-40Hz) which gives the sub a hump in response at certain notes. Also called boomy, but is actually an incorrectly design sub enclosure - design error done on purpose.

Vented enclosures do have more group delay in the lower frequencies, but group delay is less easily perceived (audible) the lower the frequency. Where typical vented subs are producing the highest group delay is in frequency bands where the delay is inaudible. I'd argue that boominess of vented subs is a myth - vented subs have much greater output at frequencies that typically then interact with room modes and cause ringing - not actually caused by the sub itself, by by the room - If you used multiple sealed subs and boosted at the low frequencies to compensate for their rollof eg to achieve a flat response similar to vented, the boominess would also exist.

To summarise, boominess is not caused by the sub, its caused by the room.

Car audio SPL type subwoofer designs also have led to this myth of vented being boomy, because they tune for maximum output at the tuning frequency (say 30-40Hz) which gives the sub a hump in response at certain notes. Also called boomy, but is actually an incorrectly design sub enclosure - design error done on purpose.

So good to be cutting again, making two large boxes at a time takes a lot longer, lol

I forgot how messy mdf if to drill, cut, 🤔

Fungers crossed i can get the basic frames glued together tomorrow. 90mm holesaw bit is chewing the batteries (not that they were fully charged from the jigsaw, drill..charge em all up over night and hook back in tomorrow morning 6more baffels (60holes ) to go

I forgot how messy mdf if to drill, cut, 🤔

Fungers crossed i can get the basic frames glued together tomorrow. 90mm holesaw bit is chewing the batteries (not that they were fully charged from the jigsaw, drill..charge em all up over night and hook back in tomorrow morning 6more baffels (60holes ) to go

Attachments

Last edited:

That looks great Trofius. Wish I had such a workshop.

Lol its juatthe garage... So far the only new tool is a table saw, for a few other projects, but router, drill, jigsaw and some enginurit, making up a jig for the outside radius'.

The tricky part, i am still dreading is the finish on the box, gloss, timber sides, front will be black, still not sure is glos or matt.... Gloss scares me lol

These will sit for a few weeks now, sadely i have to go back to work...😢 next job, laminate 5 layers of 3mm mdf and a final layer of 3mm hardwood ply.

Then add another 12 and 16mm layer to the front baffle and 12mm on top, bottom and back, then the finish.... Could be a while

Then add another 12 and 16mm layer to the front baffle and 12mm on top, bottom and back, then the finish.... Could be a while

Attachments

- Home

- Loudspeakers

- Subwoofers

- twins