Hey everyone!

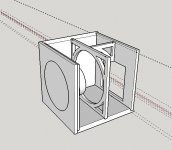

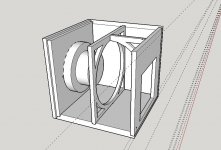

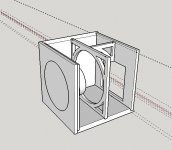

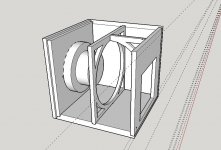

Just fininished designing the enclosure for my Dayton Reference HF 12'' 4ohm subwoofer. Its roughly 2ft^3 made from 19mm ply with double thickness front panel. The amp is probably going to be the Dayton Sudio SPA500 500W plate amp from PE. I recently discovered, after weeks of reaserch, that this is actully a Zaph Audio proven build... kind of frustrating and reassuring at the same time. Anyway, here are some screenshots of the enclusure designed on SketchUp. Let me know if there is anything I have missed or should change. It is all going to be cut using a CNC router and have a rosewood veneer with a mat-black front (matches my B&W bookshelfs).

Thanks!

Just fininished designing the enclosure for my Dayton Reference HF 12'' 4ohm subwoofer. Its roughly 2ft^3 made from 19mm ply with double thickness front panel. The amp is probably going to be the Dayton Sudio SPA500 500W plate amp from PE. I recently discovered, after weeks of reaserch, that this is actully a Zaph Audio proven build... kind of frustrating and reassuring at the same time. Anyway, here are some screenshots of the enclusure designed on SketchUp. Let me know if there is anything I have missed or should change. It is all going to be cut using a CNC router and have a rosewood veneer with a mat-black front (matches my B&W bookshelfs).

Thanks!

Put the plate amp in its own sub enclosure. Minimize the effects of vibration, etc...

Best,

Anand.

Cheers for the tip. I just did the measurments and a seperate enclosure for that amp would take up 0.41cubic foot. Thats almost a quarter of my entire enclosure. I budgeted only +20% for enternal components when doing calculations for the box. I dont want to make the box itself any bigger due to size restraints, mayber a smaller amp? Any recomendations? I noted that the MiniDSP PWR-ICE 125's are pretyt small but I am not sold on thier quality, I have seen mixed opinions... thought I finaly found the right amp but I guess its back to square one.

Anyone know a good external subwoofer amp? Could I turn the Dayton SPA500 into an external by making a box for it to sit in?

Cheers!

Decrease the ID of your centre brace. It isn't doing a huge amount at the moment.

Also I tend to avoid mitres, lap joints are easier and plenty strong enough..

Okay yeah your bracing looks pretty good. Ill give it a go.

I am using mitere joints because ill have to veneer the boards before they are cut on the CNC and lap joints won't continue the veneer around the corner.

Cheers,

Myles

Anyone know a good external subwoofer amp? Could I turn the Dayton SPA500 into an external by making a box for it to sit in?

Cheers!

I gave up on dayton plate amps, i always had problems (ground loop hum, dieing after a few months, YMMV of course). Right now I use a BASH from partsexpressive. Haven't had a single issue.

I gave up on dayton plate amps, i always had problems (ground loop hum, dieing after a few months, YMMV of course). Right now I use a BASH from partsexpressive. Haven't had a single issue.

Haha damn I just got impatient and ordered the Dayton SPA500 from PE. Oh well... thanks anyway

I was just thinking the same thing. Shoudn't be too hard. CheersHave the Cnc cut a groove for a spline in the miter or use a lock miter bit. Much easier to assemble and clamp then a plain miter.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Check out my SketchUp model. Anything to change?