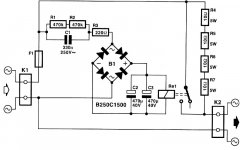

I have built a soft start circuit that was published some time ago in Elektor. I am using this circuit to power 1500VA 230V toroid for Super Leach amp. The relay is 8A constant and 15A max or 2000VA rated.

But after some time the contacts stick together. I increase the time delay to 3-4 second, but it happens again!

Any suggestions how to solve this problem?

Supernet

But after some time the contacts stick together. I increase the time delay to 3-4 second, but it happens again!

Any suggestions how to solve this problem?

Supernet

For the circuit to work the contacts suppse to stick together. When you remove supply voltage the contacts should separate. If they don't do it, it's either still power supplied to relay (the only explanation for this would be really big caps and small current draw from relay), or the relay is no good.

To be honest, I think your main problem is the relay. I have sub with 240 VA (2 x 120 VA) toriod and the relays are normal 2-pole 8 A. I have two relays, one for the main switch and one for the bypassing of a resistor (100 ohm/10 W). The main relay stick now and then but never the soft start relay.

In my second sub I have a 500 VA toriod and the relays are ELESTA SKR135 (3 x 10 A) together with a time module, very neat and very well functioning (not very cheap though).

You can always connect the relays contact in series in order to improve switching life time.

In my second sub I have a 500 VA toriod and the relays are ELESTA SKR135 (3 x 10 A) together with a time module, very neat and very well functioning (not very cheap though).

You can always connect the relays contact in series in order to improve switching life time.

Actually, you want to wire relay contacts in parallel, not series, for increased life.

Supernet:

You don't specify what you mean by the contacts sticking together. Do you mean that they permanently stick and you have to replace the relay? The contacts may be weldeding themselves closed due to excessive switching current.

Without a schematic of the circuit it's hard to be specific but in general, a relay for soft start should not engage while there is a potential for high inrush current to flow through the contacts. Perhaps you PS caps are so large and the limiting resistor such a high value that the caps have not had time to charge by the time the relay closes.

Supernet:

You don't specify what you mean by the contacts sticking together. Do you mean that they permanently stick and you have to replace the relay? The contacts may be weldeding themselves closed due to excessive switching current.

Without a schematic of the circuit it's hard to be specific but in general, a relay for soft start should not engage while there is a potential for high inrush current to flow through the contacts. Perhaps you PS caps are so large and the limiting resistor such a high value that the caps have not had time to charge by the time the relay closes.

howdy bill..

...actually contrary to intuition, wiring relay contact in parallel does nothing to increase service life i am afraid....see app. notes:

http://relays.tycoelectronics.com/application.stm

...actually contrary to intuition, wiring relay contact in parallel does nothing to increase service life i am afraid....see app. notes:

http://relays.tycoelectronics.com/application.stm

Bill Fitzpatrick said:Actually, you want to wire relay contacts in parallel, not series, for increased life.

It's quite the opposite! Why? You will decrease the time when you will have an spark. The most wearing thing for the contacts is switching of BUT also swithing on because of the contact bounces. The result is faster contact speed and that a good thing. The contact gets less effected by the hot spark.

If you connect the contacts in parallel don't exceed the current rating for one contact, because you will probely not get equal currents in the contact because of unequal contact resistances.

If you have 2 or 3-pole relay, use every pole in series if you can. This is a known trick out in the industry.

The other solution of the relay problem is to use some sort of contact protection. C or R+C across the contact. Sometimes it's not safe because the circuits isn't totally switch off but in many cases it's OK. The C in this case must be a X-type, approved for X-application.

BTW: Very good link, never come across them before.

Cut from the text:

Never parallel relay contacts to double the contact rating. Unless the relays are specially adjusted, they will not pick up and drop out simultaneously. Even if they were to be specially adjusted, they would not hold this adjustment over life.

Relay holding / sticking

One good thing I did see mentioned in the Tyco notes was the fact that using a diode shunt across the relay coils ( which is a common practice to protect the relay driver transistor ) can cause a lot of damage to the relay contacts.

how? well, the diode limits the decay rate of the residual magnetic field , which is holding the armature closed against the spring. As the field decays it reaches the point where magnetism cannot hold the armature closed any longer, the spring is stronger and the contacts then open.

with no shunt the contacts snap open quickly, ripping apart any arc-welds or deposits on them from the switch-on process.

with a diode shunt the contacts open very slowly by comparison, and may be unable to open due to the welding of the contacts ( which btw is normal, and even necessary in some relays).

series the diode shunts with zener's of an appropriate voltage ( within the specs of the driver trans) or use a MOV or similar transient suppressor. the contacts open fast again , the relay doesn't stick.

ray

One good thing I did see mentioned in the Tyco notes was the fact that using a diode shunt across the relay coils ( which is a common practice to protect the relay driver transistor ) can cause a lot of damage to the relay contacts.

how? well, the diode limits the decay rate of the residual magnetic field , which is holding the armature closed against the spring. As the field decays it reaches the point where magnetism cannot hold the armature closed any longer, the spring is stronger and the contacts then open.

with no shunt the contacts snap open quickly, ripping apart any arc-welds or deposits on them from the switch-on process.

with a diode shunt the contacts open very slowly by comparison, and may be unable to open due to the welding of the contacts ( which btw is normal, and even necessary in some relays).

series the diode shunts with zener's of an appropriate voltage ( within the specs of the driver trans) or use a MOV or similar transient suppressor. the contacts open fast again , the relay doesn't stick.

ray

Re: Relay holding / sticking

Yes, some things seems obvious but is quite the opposite. But if you really have problems with the contact, use contact protection of some kind. Very often (allways?) you must have some transient protection for the coil.

TheFettler said:One good thing I did see mentioned in the Tyco notes was the fact that using a diode shunt across the relay coils ( which is a common practice to protect the relay driver transistor ) can cause a lot of damage to the relay contacts.

Yes, some things seems obvious but is quite the opposite. But if you really have problems with the contact, use contact protection of some kind. Very often (allways?) you must have some transient protection for the coil.

Well, this is an ancient thread, but for general Interrest, I'll post.

Don't know which elector soft start circuit this is, but I had a similar problem with a soft start circuit from elector with a similarily rated relay..

This circuit used a delay acheived by charging of a pair of capacitors. As the capacitors charged, the relay would eventually close.

Now, my relay stuck in the closed position. This was probably due to welding as I had (I found out) miswired the trafo, thereby drawing very high current.

Anyway, once i got the problem solved, the relay would work fine.

The obvious answer would be that the relay is under-rated, but I think it is more likely that, assuming capacitor delay, the slow increase (and decay) of the relay coil voltage caused by the capacitor charging made the relay close and open relatively slow, thereby making it much more suceptible to arching and contact welding.

Don't know which elector soft start circuit this is, but I had a similar problem with a soft start circuit from elector with a similarily rated relay..

This circuit used a delay acheived by charging of a pair of capacitors. As the capacitors charged, the relay would eventually close.

Now, my relay stuck in the closed position. This was probably due to welding as I had (I found out) miswired the trafo, thereby drawing very high current.

Anyway, once i got the problem solved, the relay would work fine.

The obvious answer would be that the relay is under-rated, but I think it is more likely that, assuming capacitor delay, the slow increase (and decay) of the relay coil voltage caused by the capacitor charging made the relay close and open relatively slow, thereby making it much more suceptible to arching and contact welding.

Yep!

That's the one I was using!

With my 600VA toroid it is working perfectly! (after I fixed the miswiring that would cause 10A fuses to blow instantly when the reistirs were bypassed!)

I did however change the resistors to two 33ohm/17W ceramic resistors mounted off the board. Probably totally overkill as they don't show no sign of heating whatsoever, but then they will probably last..

I came across this circuit in an Elector magazine with an article on an amp called "millenium Crescendo" and was there used in conjunctionwith a 250VA toriodm, but I think I saw somewhere else that this circuit should be good for up to 1kVA.

That's the one I was using!

With my 600VA toroid it is working perfectly! (after I fixed the miswiring that would cause 10A fuses to blow instantly when the reistirs were bypassed!)

I did however change the resistors to two 33ohm/17W ceramic resistors mounted off the board. Probably totally overkill as they don't show no sign of heating whatsoever, but then they will probably last..

I came across this circuit in an Elector magazine with an article on an amp called "millenium Crescendo" and was there used in conjunctionwith a 250VA toriodm, but I think I saw somewhere else that this circuit should be good for up to 1kVA.

Sticking Relay Problem

If you use a "Force Guided Relay" it will not stick, regardless. They have silver contacts which make a great electrical connection. This type of relay is available from most electrical supply companies that service industrial control users. The relays are used as safety devices in many machine control circuits and are available in a wide array of coil voltages both AC and DC.

Rich B.

If you use a "Force Guided Relay" it will not stick, regardless. They have silver contacts which make a great electrical connection. This type of relay is available from most electrical supply companies that service industrial control users. The relays are used as safety devices in many machine control circuits and are available in a wide array of coil voltages both AC and DC.

Rich B.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Elektor soft start circuit problem