Hey there,

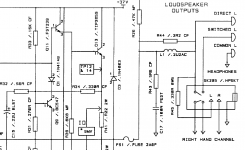

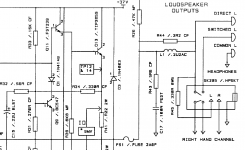

anyone got an idea how I managed to kill R43 (and the corresponding R143 in the other channel) without noticing? They're completely charred.

I am currently replacing R43 and R143 with 1/4W metal film. Originally it was carbon film, but I don't have those available. Seems I need to replace R44 and R144 as well. They're right next to the other two on the board and seem to have taken some damage from the destructive failure of R43 and R143.

Would you replace the caps in series to R43 and R143 as well? Visually they don't appear damaged, but something must have killed off those Rs...

EDIT: Thought about it again. Those resistors can only dissipate significant power if there is a lot of HF energy on the output, i. e. HF oscillation of the output stage. But why?

Kind regards,

Andreas

anyone got an idea how I managed to kill R43 (and the corresponding R143 in the other channel) without noticing? They're completely charred.

I am currently replacing R43 and R143 with 1/4W metal film. Originally it was carbon film, but I don't have those available. Seems I need to replace R44 and R144 as well. They're right next to the other two on the board and seem to have taken some damage from the destructive failure of R43 and R143.

Would you replace the caps in series to R43 and R143 as well? Visually they don't appear damaged, but something must have killed off those Rs...

EDIT: Thought about it again. Those resistors can only dissipate significant power if there is a lot of HF energy on the output, i. e. HF oscillation of the output stage. But why?

Kind regards,

Andreas

Last edited:

The resistor in the R-C network, called Zobel network, usually is much over sized in power rating to not be affected by any power output of an amp in audio frequency range under normal operation conditions. However, when the amp is unstable there could be ultrasonic frequency oscillation at the power output that's powerful enough to smoke that resistor. At such higher frequencies the 0.1uF capacitor presents a much reduced impedance, and it does little to prevent the resistor from getting burnt out.

I'd replace with 3W rating metal oxide film resistor. The capacitor almost always survive. But go ahead replace them if in slightest doubt -- they are inexpensive parts. I'd also investigate why that resistor got burnt out by putting in a 5 or 10W replacement and trying to replicate the failure mode, and addressing that first.

When a resistor in the Zobel network gets burnt, so could the tweeter in the loudspeaker have been under stress. An unstable amp could be a serious hazard.

I'd replace with 3W rating metal oxide film resistor. The capacitor almost always survive. But go ahead replace them if in slightest doubt -- they are inexpensive parts. I'd also investigate why that resistor got burnt out by putting in a 5 or 10W replacement and trying to replicate the failure mode, and addressing that first.

When a resistor in the Zobel network gets burnt, so could the tweeter in the loudspeaker have been under stress. An unstable amp could be a serious hazard.

Both charred Zobel resistor and toasted inductor parallel one show a powerful HF oscillation has happened there.

Which does not mean it is happening now, maybe once you connected a speaker load your amp did not like, Preamp oscillated, connecting cable was used with improper ground, open shield, was plugged/unplugged with amp ON, etc.

My point being that *maybe* you can´t reproduce the error.

Of course, burnt resistors don´t self heal, but remain as mute witnesses , so you will need to replace them.

Which does not mean it is happening now, maybe once you connected a speaker load your amp did not like, Preamp oscillated, connecting cable was used with improper ground, open shield, was plugged/unplugged with amp ON, etc.

My point being that *maybe* you can´t reproduce the error.

Of course, burnt resistors don´t self heal, but remain as mute witnesses , so you will need to replace them.

Both charred Zobel resistor and toasted inductor parallel one show a powerful HF oscillation has happened there.

After unsoldering the resistors, it was quite easy to see that the parallel ones were only damaged by the heat of the failing Zobel resistor. The parallels had only surface damage but were still the expected value.

The Zobel ones were completely burned. One was open, the other was 40 ohms instead of the expected 5.6 ohms.

My point being that *maybe* you can´t reproduce the error.

That's what I suspect. I do not even know how long this condition existed. I changed to more sensitive speakers yesterday and noticed some buzzing noise from the speakers which wasn't there with the older, less sensitive speakers. That was the reason to open the amp, leading to the discovery of the charred resistors.

Of course, burnt resistors don´t self heal, but remain as mute witnesses , so you will need to replace them.

I replaced all four resistors to be sure. The caps measured ok, no leakage resistance and a sensible capacitance value.

The buzzing noise is gone now, although I can not imagine how this could be caused by the inoperative Zobel network...

Regards

Andreas

If the oscillation resulted in substantial power supply loading, rectifier buzz (supply ripple) may have become audible through the amplifier's finite PSRR.The buzzing noise is gone now, although I can not imagine how this could be caused by the inoperative Zobel network...

Good catch either way; this is one of those cases where paying attention to you eyes and ears really pays off.

Are you sure the amplifier is really stable?

I know two ways to burn out those resistors:

-1- Run the amplifier with a continuous high frequency test output. You would know if you did this.

-2- Amplifier oscillating. This can be because of:

a. A really unexpected load that makes it oscillate

b. a marginal design, usually looking for high slew rate / bandwidth that oscillated by itself

Does any of the above ring any bells?

Is this a DIY amp, and if so have you perhaps been optimistic on setting the overall slew rate / bandwidth limitation?

I know two ways to burn out those resistors:

-1- Run the amplifier with a continuous high frequency test output. You would know if you did this.

-2- Amplifier oscillating. This can be because of:

a. A really unexpected load that makes it oscillate

b. a marginal design, usually looking for high slew rate / bandwidth that oscillated by itself

Does any of the above ring any bells?

Is this a DIY amp, and if so have you perhaps been optimistic on setting the overall slew rate / bandwidth limitation?

And if it is a commercial unit, have you replaced any of the transistors with substitutes? Sometime a sub with a higher Ft than the original can make a good oscillator.Is this a DIY amp, and if so have you perhaps been optimistic on setting the overall slew rate / bandwidth limitation?

Oh, that one is easy.The buzzing noise is gone now, although I can not imagine how this could be caused by the inoperative Zobel network...

Zobel is a *stability* network, so not having it often accounts for problems.

The buzing you hear may be the audible artifacts of a supersonic (inaudible) oscillation.

Lots of different ideas, thanks for the input.

1. The amp is a commercial one, an Arcam Alpha 3.

2. The unit is quite old, I think I bought it 14 years ago in used condition. It was old even back then.

3. Besides the resistors R43, R44, R143, R144 yesterday, no parts were changed yet. The rail caps are still the original ones.

4. Electrolytic capacitors: I suspected those too, but with the replaced resistors, the amp is completely quiet, apart from some random noise. I would expect to hear 50Hz or 100Hz hum if the rail caps are at the end of their useful life (and capacity).

Regards,

Rundmaus

PS. Ordered a NAD 316 BEE V2 yesterday as a replacement, but I am willing to get the Arcam back to useful operation.

1. The amp is a commercial one, an Arcam Alpha 3.

2. The unit is quite old, I think I bought it 14 years ago in used condition. It was old even back then.

3. Besides the resistors R43, R44, R143, R144 yesterday, no parts were changed yet. The rail caps are still the original ones.

4. Electrolytic capacitors: I suspected those too, but with the replaced resistors, the amp is completely quiet, apart from some random noise. I would expect to hear 50Hz or 100Hz hum if the rail caps are at the end of their useful life (and capacity).

Regards,

Rundmaus

PS. Ordered a NAD 316 BEE V2 yesterday as a replacement, but I am willing to get the Arcam back to useful operation.

Alpha 3? That's almost 30 years old. Assuming it hasn't had a previous recap of the electrolytic caps, how about making a list of suitable replacements and doing a proper service job?

Yes, I think that's the way to go. Now that a replacement is on its way, I got enough time, there's no rush to get it back to service.

Anything else besides electrolytics that might not age well? I think there are a few film capacitors which should fine. But I also spotted a few small, wound polystyrene caps. Do they have any negative aging effects? And what about the carbon film resistors the manufacturer used in many places, probably due to the price? Does it make sense to replace them all by metal films?

Kind regards,

Andreas

Polystyrene film caps are generally very long lasting and stable for precision applications. In fact all modern types of film caps will last a lifetime if they aren't subject to abuse. If there were problems they would most likely be visible as discolouring through the clear plastic film and measurable as incorrect or unstable capacitance readings.

However, I suggest that you don't try to unsolder them unless you intend to replace them. The polystyrene film melts very easily and the leads then pull out of the plastic as if they were not attached at all. If you still want to replace or remove and refit them for some reason, solder once only and allow them to cool and harden before trying again. Do it quickly and cleanly without stressing the leads, which isn't so easy to do.

However, I suggest that you don't try to unsolder them unless you intend to replace them. The polystyrene film melts very easily and the leads then pull out of the plastic as if they were not attached at all. If you still want to replace or remove and refit them for some reason, solder once only and allow them to cool and harden before trying again. Do it quickly and cleanly without stressing the leads, which isn't so easy to do.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Charred resistor on speaker output