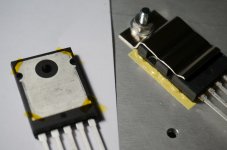

This may be a bit crazy. I did a mounting experiment by using slivers of Kapton tape as spacers in the corners of a TO-264 transistor and 5-mil phase change thermal conductive film without reenforcement. The film is Laird TPCM905 Boron Nitride filled, 0.03C-inch^2/W at best, the transistor clip is Maxclip08G by Aavid, clamping force 17 lb. The picture shows air, and perhaps excessive film material as well, was displaced after the 70-degree C, 5-minute "burn-in" recommended by the data sheet, forming bubbles around the transistor. The Kapton tape spacers seem to have sunk into the film during the phase change, and have somewhat bottomed out onto the heat sink, just as I had anticipated. There is no shorting between the heat sink and the transistor. The scheme seems to be working. What would you think of it? Perhaps risky for heat sinks that have bent or rough surface, or for those who have hard time keeping surfaces clear of metal shavings and other contaminant. But let's say we have straight and clean surfaces, will this work well and last long?

Attachments

Last edited:

Seems o/k. See how the liquid crystal material has distributed it's self on the device and the sink. I have only used Thermastrate material (no dielectric) between a device and sink.

Coverage seems good after "burn in". I like the idea of the material flowing. Maybe the excess material bubbling out is normal for this product. I get a fairly even squeeze out.

Does your material have a Film that is peeled off before use ?

Coverage seems good after "burn in". I like the idea of the material flowing. Maybe the excess material bubbling out is normal for this product. I get a fairly even squeeze out.

Does your material have a Film that is peeled off before use ?

@ART M, yes the material comes with release liner or backer paper on both sides that one can draw lines on with a pen for guiding the cutting with a pair of scissors. The liner or the backer is more rigid than the material, but the material can stand by itself without support at room temperature, like a thin sheet of very dry cheese, tacky and tends to cling on a surface. Once applied to a surface, it does not want to come off in one piece. So one most likely has only one shot in positioning it right.

@Andrew T, yes the material is supposed to expel trapped air in the interface, and it seems to be doing it well. I will do more cycles then take the assembly apart and see how well the material filled in the space.

I wil. also mount another TheralTrak transistor of the same TO-264 package close by, using silicone insulator pad, and compare the internal diode drop at temperature when the transistor is dissipating, say, 10W. This should give me a rough idea how much better the phase change material performs.

@Andrew T, yes the material is supposed to expel trapped air in the interface, and it seems to be doing it well. I will do more cycles then take the assembly apart and see how well the material filled in the space.

I wil. also mount another TheralTrak transistor of the same TO-264 package close by, using silicone insulator pad, and compare the internal diode drop at temperature when the transistor is dissipating, say, 10W. This should give me a rough idea how much better the phase change material performs.

I discovered this by accident. a thin mica isolator works better than a (very?) good "rubbery" isolator.................

I wil. also mount another TheralTrak transistor of the same TO-264 package close by, using silicone insulator pad, and compare the internal diode drop at temperature when the transistor is dissipating, say, 10W. This should give me a rough idea how much better the phase change material performs.

I have not bought any Keratherm to compare.

I took my interface apart to verify even LC material flow after burn in. Of course I had to reapply the material. I did not get any bubbling at the device edges as shown, the excess LC material squeezed out pretty evenly at the device edges. That is why I thought the LC material in this case flowed out and was trapped under a film forming bubbles. Must just be a different type of LC material with high viscosity at "burn in" temperature.

I discovered this by accident. a thin mica isolator works better than a (very?) good "rubbery" isolator.

I have not bought any Keratherm to compare.

Good to know that. Thanks. Then I'll try to find some mica, hopefully thin ones. What grease did you use with mica? I'd bet the phase change thing beats mica hands down but not with all my money in. Have you ever tried Kapton tape as an insulator? I have seen in pictures that perhaps Terry using Kapton tape as insulator with his SlewMaster builds yet not much comment about it.

Most Kapton tape is either too thick, or the adhesive is too thick, or the retailer prices it out of my reach.Good to know that. Thanks. Then I'll try to find some mica, hopefully thin ones. What grease did you use with mica? I'd bet the phase change thing beats mica hands down but not with all my money in. Have you ever tried Kapton tape as an insulator? I have seen in pictures that perhaps Terry using Kapton tape as insulator with his SlewMaster builds yet not much comment about it.

Thin Kapton with thin one sided adhesive is not available in the UK at sensible price.

No, I have never used Kapton.

I have carried out some testing on temporary heatsinks using ordinary adhesive clear tape. It works to very high temperatures in the short term. I have had sinks up to 70°C and no failures in the many minutes of heat soak operation.

I use a white Thermal compound. I have used about half of the syringe in about 20years.

I have bought over a hundred Onsemi transistors direct from Onsemi and they never sent any isolators. Same for the few dozen samples they sent.Onsemi delivers power transistor with a thin mica insulator

Last edited:

Mica seems to be ideal choice for Insulation.Rubber/silicon types deteriorates and get tried.

I am trying to test Kapton film tapes.They say Kapton is good electrical insulator as well as Thermal insulator.Ironically our case require "Thermally conducting"

I once tried 10 mil Kapton Shims for a Tda7294 gainclone IC.chip got fried within days of usage.

Then I used 2 mill Kapton tape,so far not no complaints but I am skeptical.

For once I simultaneously tested LM3886T with kapton 2 mil(Metal tabbed) against Lm3886TF(Insulated tab).Obviously LM3886 T with Kapton was cooler ,That said LM3886t and TF have different thermal/dissapation properties from Ti datasheet.So I could not come to a conclusion

Traditional Mica shims runs cooler I guess but again Mica shims are hard to find for all the desired sizes.

Ps:I always use white Heatsink compound for all my heatsink purpose.

I am trying to test Kapton film tapes.They say Kapton is good electrical insulator as well as Thermal insulator.Ironically our case require "Thermally conducting"

I once tried 10 mil Kapton Shims for a Tda7294 gainclone IC.chip got fried within days of usage.

Then I used 2 mill Kapton tape,so far not no complaints but I am skeptical.

For once I simultaneously tested LM3886T with kapton 2 mil(Metal tabbed) against Lm3886TF(Insulated tab).Obviously LM3886 T with Kapton was cooler ,That said LM3886t and TF have different thermal/dissapation properties from Ti datasheet.So I could not come to a conclusion

Traditional Mica shims runs cooler I guess but again Mica shims are hard to find for all the desired sizes.

Ps:I always use white Heatsink compound for all my heatsink purpose.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Phase Change Thermal Interface Material anyone?