Hi all,

I just want to mention that I have found an article dealing with various ESL design aspects and phenomena (mainly HF oriented) which IMHO is very, very good. Doing a search on diyaudio I cannot see that it has been mentioned here before ...

I find the article to be interesting a.o.t. because the technical/mathematical parts are accessible (to me at least), and the measurements and recommendations are very much hands-on in terms of directly using them in a practical ESL design. A link to the article is here:

AES E-Library >> Acoustic Transparency of Electrostatic Loudspeaker Assemblies ... written by D. Rod White & Stephen Bolser ...

I realize it is a "buy" article but, although I in this case I was helped by our libraries, I would consider it worth the cost (again IMHO).

Cheers,

Jesper

I just want to mention that I have found an article dealing with various ESL design aspects and phenomena (mainly HF oriented) which IMHO is very, very good. Doing a search on diyaudio I cannot see that it has been mentioned here before ...

I find the article to be interesting a.o.t. because the technical/mathematical parts are accessible (to me at least), and the measurements and recommendations are very much hands-on in terms of directly using them in a practical ESL design. A link to the article is here:

AES E-Library >> Acoustic Transparency of Electrostatic Loudspeaker Assemblies ... written by D. Rod White & Stephen Bolser ...

I realize it is a "buy" article but, although I in this case I was helped by our libraries, I would consider it worth the cost (again IMHO).

Cheers,

Jesper

Jesper, thanks for drawing attention to this paper. I had noticed it at the time the JAES issue appeared, but never got around to reading it. We get to learn about some acoustic mechanisms that explain a few perturbations in measured responses.

Good to see our friend Bolserst co-authoring an AES paper. Being the modest guy he is, he has refrained from trumpeting his achievements to all and sundry. I think his New Zealand colleague has also posted on this forum.

Keith

Good to see our friend Bolserst co-authoring an AES paper. Being the modest guy he is, he has refrained from trumpeting his achievements to all and sundry. I think his New Zealand colleague has also posted on this forum.

Keith

Hi Keith & WrineX,

Yes, it appears to be written by diyaudio members .. As I personally have some focus on HF phenomena as a key aspect of sound reproduction I found it very interesting and at the same time accessible which is also important to me ...

And, on a sidenote,

Cheers,

Jesper

Yes, it appears to be written by diyaudio members .. As I personally have some focus on HF phenomena as a key aspect of sound reproduction I found it very interesting and at the same time accessible which is also important to me ...

And, on a sidenote,

... I learned a new expression reading your post (Keith) - I never heard this "all and sundry" before but I understand that it means everybody, everyone ... well, there's always something to learn ;-)to all and sundry

Cheers,

Jesper

This sounds interesting.

Reference to perforated plate stators, I assume means directly applicable to both Quad 57 and Martin Logan type stators, but wondering how much work there might be in adapting this to wire and egg crate type stator and support systems like Quad 63 and Acoustat?

Kind Regards

Grantn

PS: Will buy the paper and without any electrical engineering background, have a play myself. 😀

Reference to perforated plate stators, I assume means directly applicable to both Quad 57 and Martin Logan type stators, but wondering how much work there might be in adapting this to wire and egg crate type stator and support systems like Quad 63 and Acoustat?

Kind Regards

Grantn

PS: Will buy the paper and without any electrical engineering background, have a play myself. 😀

Attachments

Last edited:

.... wondering how much work there might be in adapting this to wire and egg crate type stator and support systems like Quad 63 ...

The Quad 63 type design sure looks like it could do with some modelling to deal with high frequency hash judging by Stereophile measurements - even with the socks down:

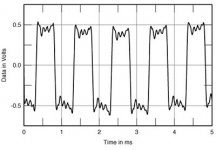

Quad ESL-63, 1kHz squarewave response on listening axis at 1m

Thats an amazing square wave except for the 12kHz ring riding on it.

But 12kHz is very high. There's no fundamental tones up there. Often theres not much energy recorded over 12kHz anyway. Then plenty of us have developed a low pass hearing filter to further reduce influence of those high frequencies. Does it matter?

Looks like Sander's can do magic in the high frequencies.

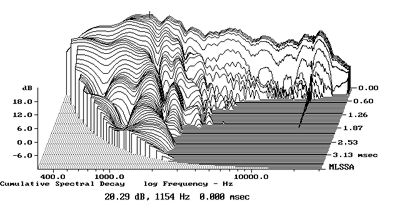

InnerSound Eros Mk.III, cumulative spectral-decay plot at 50"

What the secret?

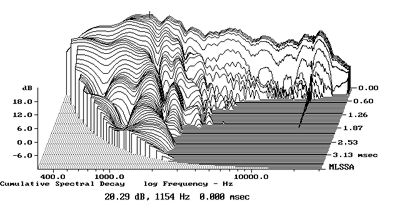

InnerSound Eros Mk.III, cumulative spectral-decay plot at 50"

What the secret?

An externally hosted image should be here but it was not working when we last tested it.

The modeling technique is applicable to wire stators as well as perforated plate stators with slots rather than staggers holes. The main difference is the end-correction factor used for defining the effective acoustic thickness of the stators. Besides stators, the model also allows you to quantify the effect of damping mesh and dust covers like Quad uses. I posted some results of using the modeling method for dust cover reflections vs measurements a couple years ago. Dust Covers…Reference to perforated plate stators, I assume means directly applicable to both Quad 57 and Martin Logan type stators, but wondering how much work there might be in adapting this to wire and egg crate type stator and support systems like Quad 63 and Acoustat

Feel free to post any questions on how to use the model for a particular situation. If there is interest, at some point I can post an example spreadsheet having calculations for the simple case of perforated stators with equal size gaps and no damping mesh or dust covers. For more complicated configurations, using LTspice for simulation is the easier approach.

Indeed...golfnut here on diyAudio. You may recall his thread showing a practical realization of his previous AES article on segmented ESLs.…I think his New Zealand colleague has also posted on this forum.

Another segmented ESL

Very gratifying to hear your description of the article including the words accessible and practical.…I find the article to be interesting a.o.t. because the technical/mathematical parts are accessible (to me at least), and the measurements and recommendations are very much hands-on in terms of directly using them in a practical ESL design…

We certainly were trying to provide useful information rather than just mathematical obfuscation.

In golfnut’s previous AES paper on ESLs he noted the simple relationships between stator voltage/current and SPL for ESLs using different forms of the Walker equation. However, the relationships are based on the assumption that the diaphragm and stator assemblies are acoustically transparent...which practical experience says they are not. Both of us had been independently seeking methods to model and quantify what was going on in the upper octaves. The present paper is the result of a collaborative effort spanning several years to understand the theory, verify with experiments, and develop a simple modelling method that properly captured the HF behavior. Our disparate backgrounds and approaches were truly beneficial, and I don’t think either of us would have reached as successful a conclusion alone.

Last edited:

Hi All

Thanks for the kind words.

For those that want to get a copy of the paper and are not members of AES, I’m sorry, for copyright reasons we cannot simply post a pdf of the paper. There are a couple of legal alternatives.

You could try asking a local university library if they subscribes to JAES, and whether they would let you read the journal, or provide a copy for a smaller fee.

Send me a PM including a personal email address, I can send a copy of the pre-publication manuscript (we are allowed to do that).

Regards

Thanks for the kind words.

For those that want to get a copy of the paper and are not members of AES, I’m sorry, for copyright reasons we cannot simply post a pdf of the paper. There are a couple of legal alternatives.

You could try asking a local university library if they subscribes to JAES, and whether they would let you read the journal, or provide a copy for a smaller fee.

Send me a PM including a personal email address, I can send a copy of the pre-publication manuscript (we are allowed to do that).

Regards

Good to see this! Nice work guys. Always good to see such charcture recognized.

Question..

awhile back I was playing around with "screens" for some ribbon work. Eventually found some perforated metal that had a larger open area than the typical round hole stuff. This one had hexagonal holes each about .2 inch diameter,and I think the open area was around 80 %. The best I have found in the round hole variety was about 65% open area.

What effect do you think this might have in an esl? On the ribbon I could see no change at all in the HF response. The 63% round hole variety showed some loss in HF sensativity. Did not measure anything else.

McMaster-Carr

Question..

awhile back I was playing around with "screens" for some ribbon work. Eventually found some perforated metal that had a larger open area than the typical round hole stuff. This one had hexagonal holes each about .2 inch diameter,and I think the open area was around 80 %. The best I have found in the round hole variety was about 65% open area.

What effect do you think this might have in an esl? On the ribbon I could see no change at all in the HF response. The 63% round hole variety showed some loss in HF sensativity. Did not measure anything else.

McMaster-Carr

yea my work suggests that the more open the better, however with thin film diaphragms we often want some damping in the form of acoustic resistance which implies less open area.

In some lower mass full range planer magnetic work (3 micron film/4 micron foil) I used the larger open area / less physical structure size screen (which is very flimsy), with a very fine weave nylon mesh (cant remember what size but small open area), glued to the perforated metal, then all that was supported/damped by rectangular steel rods for structural rigidity and mass and damping. The steel rods btw were 2 rods laminated with viscoelastic between.

I found trying to make this structure too rigid was not the best way to go and that mass and damping were more important.

I wanted to try simply laminating two sheet of the hexagonal 80% open perf steel together with contact adhesive to get good mass/rigidity/damp to eliminate the steel rods to support. Never built one but did make a small sample and it was much stiffer and much better damped than single layer. I suspect however that if the panel is larger than about 6-7 inches wide would still need support. As well now we have made the depth of the open sections deeper which may upset HF extension??

In some lower mass full range planer magnetic work (3 micron film/4 micron foil) I used the larger open area / less physical structure size screen (which is very flimsy), with a very fine weave nylon mesh (cant remember what size but small open area), glued to the perforated metal, then all that was supported/damped by rectangular steel rods for structural rigidity and mass and damping. The steel rods btw were 2 rods laminated with viscoelastic between.

I found trying to make this structure too rigid was not the best way to go and that mass and damping were more important.

I wanted to try simply laminating two sheet of the hexagonal 80% open perf steel together with contact adhesive to get good mass/rigidity/damp to eliminate the steel rods to support. Never built one but did make a small sample and it was much stiffer and much better damped than single layer. I suspect however that if the panel is larger than about 6-7 inches wide would still need support. As well now we have made the depth of the open sections deeper which may upset HF extension??

Last edited:

One things for sure....working with my minny prs of Apogee stages...the holes in the medal that holds the magnet ....for the mid-bass ribbon driver...I think it the same size holds on all the Apogee..adding any dap to this medal made a Big diff in sound,tone...pulling one or two screws.... .it was.. like you could tune the sound....but I always ended you with no dap added

Its a bit different situation with the Apogee bass system. The mass of the diaphragm is much higher AND its not being asked to do high freq.

The open area of the Apogee bass magnet assembly (magnets and perforated steel plate) is only about 12% ! , and this open area is critical to tailoring the level of rise in output at resonance as well as taming some mid range diaphragm misbehavior.

A good tuning method on these higher mass bass panels is simply blocking off a small section with a stiff board( crude method). This to lower the somewhat overblown level at the low end, and to allow a bit more power handling. I used to just block off with thick tape

The open area of the Apogee bass magnet assembly (magnets and perforated steel plate) is only about 12% ! , and this open area is critical to tailoring the level of rise in output at resonance as well as taming some mid range diaphragm misbehavior.

A good tuning method on these higher mass bass panels is simply blocking off a small section with a stiff board( crude method). This to lower the somewhat overblown level at the low end, and to allow a bit more power handling. I used to just block off with thick tape

Using 80% open area stators that are only 0.03” thick would result in the HF response behavior of an ESL being completely dominated by the first order roll off due to diaphragm mass…very little ripple from stator reflections. Ignoring the already mentioned need for rigid stators, some other downsides are:…This one had hexagonal holes each about .2 inch diameter, and I think the open area was around 80 %...What effect do you think this might have in an esl?

- loss of sensitivity. With typical 2mm spacing between the diaphragm and stators, you would lose about 4-5dB of sensitivity.

More details on relationship between stator % open area and sensitivity here: First time ESL builder

- loss of uniformity of drive force on the diaphragm…tends to add a harshness or glare to the sound

That is correct. Increasing the thickness of the perforated sheet(even with 80% open area) will increase the HF roll-off and increase the magnitude of ripples in the response when placed close to a very light diaphragm as in an ESL. With thicker/heavier aluminum ribbons this will be less of an issue.…I wanted to try simply laminating two sheet of the hexagonal 80% open perf steel together with contact adhesive to get good mass/rigidity/damp ...now we have made the depth of the open sections deeper which may upset HF extension??

BTW, the same modeling technique developed in the paper for ESLs can be used for evaluating planar magnetics(single sided or push-pull), or individual components like a perforated plate.

what about the screens Apogee used....any loss of high frec...chep that's for sure..stop people putting there finger though....helpet anyway..

An what up with Analysis Audio using speaker cloth for there mid-bass. what you say lowmass...thanks

Yes the screen Apogee used I believe is just PVC coated fiberglass window screen can get at hardware store.

I measure 1 db loss at 20k with that screen and no loss well below that.

I did "tests" on a number of "screens" and "speaker cloths" on heavier planer magnetic bass designs and mid tweeter ribbon designs all close to same mass as the Apogees.

In the end I did see some change in sound on the bass panels IF the "speaker cloth" was too heavy and too restrictive. The cloth would move in sympathy with the bass panel adding to its moving mass and lowering sensativity and gave a subjectively less dynamic quality.

On the mid tweet ribbons if the "cloth" was to heavy /restrictive there was simply a loss of high freq proportional to the cloths weight and tightness of weave. These were small changes however and I did not do detailed analysis on any to get numbers people could use. I quickly moved through the experiments, got a good seat of the pants feel for what did what and moved on.

I dont know what Analysis uses as "cloth" so cant say but if its light and loe restriction it probably fine. However their bass panel design is quite different that typical tensioned film as I believe they have a lower Q suspension system of some kind. Probably more damped at main resonance than other planers but cant say for sure.

Last edited:

Using 80% open area stators that are only 0.03” thick would result in the HF response behavior of an ESL being completely dominated by the first order roll off due to diaphragm mass…very little ripple from stator reflections. Ignoring the already mentioned need for rigid stators, some other downsides are:

- loss of sensitivity. With typical 2mm spacing between the diaphragm and stators, you would lose about 4-5dB of sensitivity.

More details on relationship between stator % open area and sensitivity here: First time ESL builder

- loss of uniformity of drive force on the diaphragm…tends to add a harshness or glare to the sound

That is correct. Increasing the thickness of the perforated sheet(even with 80% open area) will increase the HF roll-off and increase the magnitude of ripples in the response when placed close to a very light diaphragm as in an ESL. With thicker/heavier aluminum ribbons this will be less of an issue.

BTW, the same modeling technique developed in the paper for ESLs can be used for evaluating planar magnetics(single sided or push-pull), or individual components like a perforated plate.

Very good. Thanks bolserst

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Superb article on HF ESL phenomena (IMHO)