some preliminary remarks in the meantime said:This thread was started to tackle my first and most pressing questions I had when I began working on an Econowave-inspired, Hypex-powered digital 2-Way speaker.

Throughout the course of my trials and errors, reading and simultaneous developements elsewhere, I learned some assumptions that where stated by the original developers had to be discarded. Most noteworthy the asymmetric waveguide and the close center-to-center distancing. Using the speakers from a floor level also does not make sense and a much more aggressive EQ-ing could be done. If one is not in pursuit of absolute audio perfection, on could state the question whether it is actually neccessary to use such big boxes. Given that power is cheap and active solutions with DSP abilities are readily at hand and many big commercial manufacturers implement heavy DSPing in ther Pro grade products.

Without a doubt, if a passive solution was intended, I would now pursue a floor standing, tall but shallow box, as this is needed for a good position of the image anyway and also due to volume considerations, and would possibly implement a free-stand waveguide on top. With DSP and ample power at hand, I will instead look into minimizing the footprint. This is why my endeavour has not ended and is still in the making.

Please understand this thread as an ongoing elaboration of what is actually needed by a certain user type and what can be achieved with some compromises. Over the time, I will annotate my findings in the first post as a list and resource.

Last edited:

Recently I began to question whether the most widely circulated set of goals in this direction of speaker type is actually needed for a certain user class.

This speaker type comes from at least two directions:

With ample power at hand and DSP solutions readily available, I question, if one is willing to accept some deterioration in sound quality due to the use of more aggressive filters, the concept could be shrank down to a 10-inch speaker while still achieving essentially a full range response. This obviously only makes sense if one is not after the obvious advantages of distributed subs and willing to sacrifice some performance especially in the low frequencies. Adapting the dimensions of Earl Geddes first Nathan 10 speaker Building the Nathan 10, with 15mm wood sheets, one can achieve some 30 liters netto volume with an enclosure of 60 x 30 x 25 cm, a domesticized speaker, but, I fancy, still very potent. The JBL 708P 8-inch studio monitor showed very good performance with a much smaller package already and relies, I assume, on heavy use of filters, too.

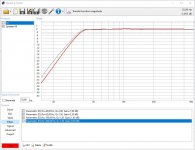

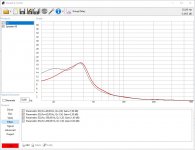

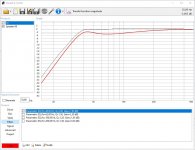

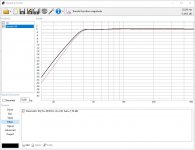

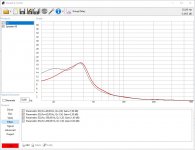

Some stronger use of filters is needed. I put a Faital 10PR320 into WinISD and needed 4 PEQs to get a comparable result from the 10-inch driver in a 30 liter box to that what is currently implemented with a 12-inch drinver in a 50 liter box. Despite the heavy use of filters, the amplifier load seems okay, the maximum SPL is still good for most listeners and group delay did not change dramatically to the worse (given that the PEQ already introduced some considerable sluggishness, maybe a case for later FIR). Have I overlooked something? Is this a bad idea or do you think it is feasible? Would love to hear your opinion!

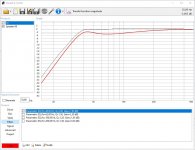

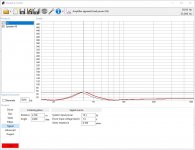

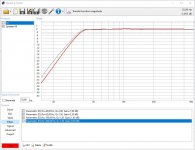

30 liters / 10-inch with one PEQ (assisted 6th order as per Keele)

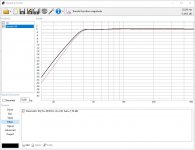

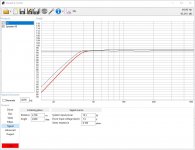

530 liters / 12-inch with one PEQ (assisted 6th order as per Keele)

30 liters / 10-inch with four PEQs

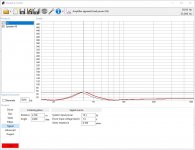

Group delay did not change to to worse anymore

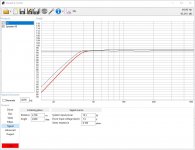

Amplifier load is okay

SPL at LP seem to be okay too

This speaker type comes from at least two directions:

- a cheap alternative to controlled directivity horns as popularized in 1980s JBL commercial speakers, essetially striving for a passive full range response

- as a high-end speaker for enthusiasts with a high degree of controll over first and early reflections, but combined with multiple subs to overcome modal issues in the bass response.

With ample power at hand and DSP solutions readily available, I question, if one is willing to accept some deterioration in sound quality due to the use of more aggressive filters, the concept could be shrank down to a 10-inch speaker while still achieving essentially a full range response. This obviously only makes sense if one is not after the obvious advantages of distributed subs and willing to sacrifice some performance especially in the low frequencies. Adapting the dimensions of Earl Geddes first Nathan 10 speaker Building the Nathan 10, with 15mm wood sheets, one can achieve some 30 liters netto volume with an enclosure of 60 x 30 x 25 cm, a domesticized speaker, but, I fancy, still very potent. The JBL 708P 8-inch studio monitor showed very good performance with a much smaller package already and relies, I assume, on heavy use of filters, too.

Some stronger use of filters is needed. I put a Faital 10PR320 into WinISD and needed 4 PEQs to get a comparable result from the 10-inch driver in a 30 liter box to that what is currently implemented with a 12-inch drinver in a 50 liter box. Despite the heavy use of filters, the amplifier load seems okay, the maximum SPL is still good for most listeners and group delay did not change dramatically to the worse (given that the PEQ already introduced some considerable sluggishness, maybe a case for later FIR). Have I overlooked something? Is this a bad idea or do you think it is feasible? Would love to hear your opinion!

30 liters / 10-inch with one PEQ (assisted 6th order as per Keele)

530 liters / 12-inch with one PEQ (assisted 6th order as per Keele)

30 liters / 10-inch with four PEQs

Group delay did not change to to worse anymore

Amplifier load is okay

SPL at LP seem to be okay too

In general more power means more excursion and more heat, which translate to distortion and compression. I'm not sure if you detect this in any meaningful way between 10" and 12" in home environment where the SPL levels are comfortable and modest most of the time.

I think there is something with big woofer SD, more tactile feel, but that might have been due to higher SPL which is possible with the big SD with small power, but SPL is also possible with more power and smaller SD albeit bit more distortion and compression potential. You should try a smaller box to be sure if it is enough for you. I'd say you should finish this project and then build another project /proto and compare side by side. You should be able to pick up if there is any meaningful difference. Size and looks of the system is very important at home so if same sound quality can be achieved in smaller package it is better. Unless the macho / status effect of big speakers is important which sometimes is. For music lover it is all about quality, enough bandwidth and SPL capability without problems that bother, comfortably loud dynamic reproduction.

Building stuff, learning from it, and building improved version or variation is exactly how you get good sound system for you! Have fun!

I think there is something with big woofer SD, more tactile feel, but that might have been due to higher SPL which is possible with the big SD with small power, but SPL is also possible with more power and smaller SD albeit bit more distortion and compression potential. You should try a smaller box to be sure if it is enough for you. I'd say you should finish this project and then build another project /proto and compare side by side. You should be able to pick up if there is any meaningful difference. Size and looks of the system is very important at home so if same sound quality can be achieved in smaller package it is better. Unless the macho / status effect of big speakers is important which sometimes is. For music lover it is all about quality, enough bandwidth and SPL capability without problems that bother, comfortably loud dynamic reproduction.

Building stuff, learning from it, and building improved version or variation is exactly how you get good sound system for you! Have fun!

Last edited:

How is group delay properly measured with REW?

When I look at my results I get the horrors and I hope it is just me not using the software right. I always thought that I had to measure far field, i. e. 1m, and exclude the room somehow. But there is severeal issues:

1) A gate cannot be used, otherwise the LF is cut, correct? Now I wonder how I can actually see the group delay of the woofer without the room modes.

Then, there is HF reflections:

2) Is a frequency dependet window applied and if, how many ms/cycles set?

When I look at my results I get the horrors and I hope it is just me not using the software right. I always thought that I had to measure far field, i. e. 1m, and exclude the room somehow. But there is severeal issues:

1) A gate cannot be used, otherwise the LF is cut, correct? Now I wonder how I can actually see the group delay of the woofer without the room modes.

Then, there is HF reflections:

2) Is a frequency dependet window applied and if, how many ms/cycles set?

This article says in ARTA the gate is applied to exclude room reflections:

https://audiojudgement.com/group-delay-explanation-measurement-audio/But in REW if I do this the low end of the graphs is cut usually both in FR and in GD view according to right window

https://audiojudgement.com/group-delay-explanation-measurement-audio/But in REW if I do this the low end of the graphs is cut usually both in FR and in GD view according to right window

The article saysThis article says in ARTA the gate is applied to exclude room reflections:

"To get the group delay information for the lower frequencies, we need to make a nearfield measurement".

Using an FDW in REW is one way to get a cleaner look at an in room response anywhere from 15 cycles down will clean up the worst but maybe need to be as low as 4 to 6.

To look at the group delay of the speaker alone nearfield or outdoors is the better option.

With REW setting IR gating to eg. 30ms gives and psychoacoustic smoothing gives rather nice looking GD, even in-room at 1m (spot measurement typically has too many reflections)

https://data-bass.com/#/articles/5cc0bc36a75a260004255c88?_k=qab310

FDW means Frequency Dependant Windowing and one sets how many cycles to count, and that reflects to smoothing (6 cycles is 1/8oct)

Nearfield measurement (1cm) catches only one driver, but semi-anechoic at 1m sums rather nicely even a typical 3-way speaker. and reveals baffle step effect, diffractions and interferences that remain unknown with nearfield.

Excess goup delay is higher with higher order LR xo, and one "knows" that without measurements. Bass roll-off adds EGD smoothly, but bass-reflex tunig makes EGD go wild, because it makes full cycle delay at tuning frequency.

I personally feel that I don't need to see GD from measurements of my own projects, because I know the xo, tuning and eq used. But when testing ready-made commercial speakers, step response and GD give info about those. Nearfield response of bass driver (and port/PR) are important too.

https://data-bass.com/#/articles/5cc0bc36a75a260004255c88?_k=qab310

FDW means Frequency Dependant Windowing and one sets how many cycles to count, and that reflects to smoothing (6 cycles is 1/8oct)

Nearfield measurement (1cm) catches only one driver, but semi-anechoic at 1m sums rather nicely even a typical 3-way speaker. and reveals baffle step effect, diffractions and interferences that remain unknown with nearfield.

Excess goup delay is higher with higher order LR xo, and one "knows" that without measurements. Bass roll-off adds EGD smoothly, but bass-reflex tunig makes EGD go wild, because it makes full cycle delay at tuning frequency.

I personally feel that I don't need to see GD from measurements of my own projects, because I know the xo, tuning and eq used. But when testing ready-made commercial speakers, step response and GD give info about those. Nearfield response of bass driver (and port/PR) are important too.

My local timber wholesaler told me they are selling their last sheets of plywood. They hope for one more truck arriving from Russian federation, but that is it and they are even doubtful if this will happen. So I will drive there tomorrow and get myself some wood. Many here tend to use really thick plywood, while commercial producers often use much thinner boards.

Is 18 mm, 3/4 inch good enough? Speaker external dimensions will be about 60 cm by 31 by 28. I was always thinking to go thicker, but I will brace it anyway and do not want the heaviest chunk in town. What do you think?

Is 18 mm, 3/4 inch good enough? Speaker external dimensions will be about 60 cm by 31 by 28. I was always thinking to go thicker, but I will brace it anyway and do not want the heaviest chunk in town. What do you think?

Partly  I do think that 18mm is enough if you're using plywood and good bracing. Other part is about getting the material while you still can.

I do think that 18mm is enough if you're using plywood and good bracing. Other part is about getting the material while you still can.

I'm supposed to build a house this year and i'm really worried about the price and availability of lumber for roof framing if RF implements sanctions.

I'm supposed to build a house this year and i'm really worried about the price and availability of lumber for roof framing if RF implements sanctions.

Troels says 18-22, and if 18, add bitumen:

Well, maybe even 16 is alrite then! 😂Cabinets were made from 20 mm Baltic birch throughout. You can use BB or MDF from 18-22 mm. Stick to front panel dimensions and drivers' placement. If you're down to 17-18 mm panels, add 4 mm bitumen padsto your purchase and clad sides, top and bottom and rear panels.

I think I had asked this before, but:

When covering the walls with a polypropylen fabric (1kg/m³) like such https://www.ebay.de/itm/251431684997?var=550349547417,

which ratio to the gross volume would applied to calculate the netto volume lost?

For example, if the volume at the walls which is filled with fabric accounts for 10 gross liters, but the fabric is not solid and air is moving inside it, the volume is not reduced by the full amount. Half of it? A third? Two thirds?

Anyone?

When covering the walls with a polypropylen fabric (1kg/m³) like such https://www.ebay.de/itm/251431684997?var=550349547417,

which ratio to the gross volume would applied to calculate the netto volume lost?

For example, if the volume at the walls which is filled with fabric accounts for 10 gross liters, but the fabric is not solid and air is moving inside it, the volume is not reduced by the full amount. Half of it? A third? Two thirds?

Anyone?

Stuffing tends to make the cabinet look larger, unless it is too dense, so it can go either way. When unsure, you might assume that it has no net effect on volume.

I don't agree with the quote from your earlier post. Damping is not there to make up for reduced wall thickness. In fact, if you use thicker walls and the resonances are pushed to higher frequencies, couldn't that sometimes mean that the bitumen panels are more necessary?

I don't agree with the quote from your earlier post. Damping is not there to make up for reduced wall thickness. In fact, if you use thicker walls and the resonances are pushed to higher frequencies, couldn't that sometimes mean that the bitumen panels are more necessary?

This is usual damping to work against resonances, troels uses felt and I learned from Rese’s Asathor manual that PP lining used for garden ponds is a cheap option. It counters resonances quite well, see https://www.diyaudio.com/community/threads/digital-bsc-question.370349/post-6676654

Have you tried simulating some reduction, eg 5 litres? If it is not bad then why not measure after you build. You can compensate when the effective volume of a vented enclosure is too small by adding more stuffing of the appropriate density. I think Winisd might be able to do that, I'd have to check.

Two thinner panels glued together with a lossy glue of some kind can work as well or better than a thick panel. Thicker panels and adding bitumen pads is aiming for mass damping and extra stiffness. The stiffness can be achieved with the right bracing and shear damping from the constrained layer can be more effective at creating loss than mass. Combining two dissimilar materials like mdf and ply for the layers can also work well.Troels says 18-22, and if 18, add bitumen:

Well, maybe even 16 is alrite then! 😂

The felt that you are looking at doesn't do much to affect the apparent box volume but it is very effective at damping internal reflections.

- Home

- Loudspeakers

- Multi-Way

- Digital BSC question