New user here so be gentle. I own a pair of B&W Speakers that I inherited from a late friend who was a serious audiophile however this pair have a little bit of a "history" as they are quite genuine speakers that were in I believe B&W's acoustic test chamber (so no serial numbers) and were obtained for my late friend by a B&W engineer who the last time I heard anything of was living in Toulouse and fitting the electronics into Airbus A380's.

This morning one of the speakers failed, I had been doing some work fitting some external fans onto the amplifier as it was running hot. Since then, dead speaker. I took it apart earlier and its a DM2A Issue 2 circuit board, checked some of the circuit diagrams on here and thought the culprit was the 10 ohm resistor at R1 had got hot and failed as I could see heat damage on the circuit board. However once I removed the R1 resistor and tested it on the multimeter it was reading just about a perfect 10 ohms.

I have attached some images of the board apologies if I have used the wrong image host for here, however I'm no audiophile nor an expert on speakers and I am quite stuck to diagnose the issue here so any suggestions or pointers very much welcome.

This morning one of the speakers failed, I had been doing some work fitting some external fans onto the amplifier as it was running hot. Since then, dead speaker. I took it apart earlier and its a DM2A Issue 2 circuit board, checked some of the circuit diagrams on here and thought the culprit was the 10 ohm resistor at R1 had got hot and failed as I could see heat damage on the circuit board. However once I removed the R1 resistor and tested it on the multimeter it was reading just about a perfect 10 ohms.

I have attached some images of the board apologies if I have used the wrong image host for here, however I'm no audiophile nor an expert on speakers and I am quite stuck to diagnose the issue here so any suggestions or pointers very much welcome.

Can you explain what was going on when the speaker failed?

If you can measure a 10ohms resistor, you should be able to measure the voice coil resistance of each of the drivers in isolation.

I guess somewhere between 2-16 ohms will at least suggest if the drive units are serviceable, An open circuit or a value greater than 16 ohms could be an indicator of the problem.

You probably should hear a crackle from the driver as you connect the dvm probes when trying to measure the voice coil resistance.

Be gentle as these are old speakers now and the wiring tags maybe fragile.

If you can measure a 10ohms resistor, you should be able to measure the voice coil resistance of each of the drivers in isolation.

I guess somewhere between 2-16 ohms will at least suggest if the drive units are serviceable, An open circuit or a value greater than 16 ohms could be an indicator of the problem.

You probably should hear a crackle from the driver as you connect the dvm probes when trying to measure the voice coil resistance.

Be gentle as these are old speakers now and the wiring tags maybe fragile.

I was trying to fix a "crackle" in the left hand speaker, I originally thought it was down to a bad connection somewhere and renewed the bare wire connections to the speakers using Nakamichi banana plugs and everything worked fine, but while I was testing it out I found the top of the amp to be getting rather warm (Its a Sony TA-FB930R) and ordered a pair of USB powered AC Infinity fans to go on top of the amp to pass air over the heatsinks. When I re-powered the amp the right side worked fine, but nothing out of the left speaker, I tried the cables in the "B" output of the amp and got the same, tested the cables for continuity and they were fine, tested the output of the amp and got around 14V. I even tried plugging the right hand cables in as a test and it was still dead.

I checked the coils on the circuit board, and got readings between 5 -7 ohms for them I'm reluctant to unsolder each one as if you look closely at the attached pictures someone at B&W was very generous with what I suspect is Araldite. The speaker drivers all sound right they all "crackled" softly when I used the test probes.

I checked the coils on the circuit board, and got readings between 5 -7 ohms for them I'm reluctant to unsolder each one as if you look closely at the attached pictures someone at B&W was very generous with what I suspect is Araldite. The speaker drivers all sound right they all "crackled" softly when I used the test probes.

Is there a fuse at the rear connector panel?

I had to ask as some speakers from that era had a fuse on a nameplate or rear panel?

I had to ask as some speakers from that era had a fuse on a nameplate or rear panel?

A 14V ac signal would be rather loud i imagine into these loudspeakers if working well.

I hope you do not mean you measured 14V dc at the output?

14millivolts dc would be better?

I hope you do not mean you measured 14V dc at the output?

14millivolts dc would be better?

If the drivers alone connected to the amp are working, and if connected to the crossover all don't, then it is a fuse broken.

Ralf

Ralf

No fuse and apologies for the typo the output was 14 mV. The only thing I cant test 100% is the ITT capacitors, though I have done a continuity test across just about everything and the only thing I can find is that the C6 Capacitor (ITT PM2R 68/100) shows no continuity.

I take it that the other capacitors slowly increase resistance when measured and quickly swapping the leads causes them to show low and then again slowly increase resistance which is what you would expect.

68/100 possibly means 6.8uF 100Volt DC working, we need to find a thread about DM2A crossovers or a google schematic.

68/100 possibly means 6.8uF 100Volt DC working, we need to find a thread about DM2A crossovers or a google schematic.

The crossover is shown here: https://bwgroupsupport.com/manuals/bw-service

The C6 cap is 0.68uF, but even if it fails, it will only stop the tweeter and not the whole speaker.

You have a continuity problem between the crossover and the terminals, as a test attach the amp cables directly to the + and + tabs on the crossover plate (be careful).

Ralf

The C6 cap is 0.68uF, but even if it fails, it will only stop the tweeter and not the whole speaker.

You have a continuity problem between the crossover and the terminals, as a test attach the amp cables directly to the + and + tabs on the crossover plate (be careful).

Ralf

Old things can be problematical, I am one.

Loose wire, corrosion or soldering, a small hairline crack on a pcb trace etc the switch assembly but that should only effect the mid range. Wiring loom and traces should be below 1ohm when checked for continuity.

Now that Ralf has given us a link to the Xover it should be easier to diagnose the issue.

When you connect the bad speaker can you hear the amp protection relay click across to protect the amp assuming it has a protection circuit?

Loose wire, corrosion or soldering, a small hairline crack on a pcb trace etc the switch assembly but that should only effect the mid range. Wiring loom and traces should be below 1ohm when checked for continuity.

Now that Ralf has given us a link to the Xover it should be easier to diagnose the issue.

When you connect the bad speaker can you hear the amp protection relay click across to protect the amp assuming it has a protection circuit?

Last edited:

I think Ralf is right about a continuity issue but before I run his suggested test I want to replace the R1 resistor I removed with one that's seen better days first as its reading ok but its heat damaged and there are some hairline cracks in the exterior coating.

I ordered a ceramic wirewound 10W 10 ohm replacement along with some spare mid-range speaker wire this morning as testing it with new wire seems a sensible action.

I found the service and user manual for the Amp online this morning, I can hear the relay in the amp click on and the "Protection" led lights up on power on and then goes off which is what it should do according to the manual.

I will do a re-test on the capacitors for resistance tomorrow, its mothers day and I don't have the time to spare

I ordered a ceramic wirewound 10W 10 ohm replacement along with some spare mid-range speaker wire this morning as testing it with new wire seems a sensible action.

I found the service and user manual for the Amp online this morning, I can hear the relay in the amp click on and the "Protection" led lights up on power on and then goes off which is what it should do according to the manual.

I will do a re-test on the capacitors for resistance tomorrow, its mothers day and I don't have the time to spare

Update, I ran the resistance check on all the capacitors and the all seem to be good, Including the C6 Capacitor which may have just been "open" when I first tested it.

One question while I am ordering parts etc, I noticed that the old slip on insulation over the speaker cable connection (The "Jones" Cinch Connector P/N JA778450000E000 ) is degraded. Is it worth ordering a replacement plug and reconnecting the wires with more modern heat shrink or just cut off the degraded insulation and use electrical tape. I'm only asking as the only source I can find for that part is RS and they want £4.95 to ship a £1.05 component 🙁

One question while I am ordering parts etc, I noticed that the old slip on insulation over the speaker cable connection (The "Jones" Cinch Connector P/N JA778450000E000 ) is degraded. Is it worth ordering a replacement plug and reconnecting the wires with more modern heat shrink or just cut off the degraded insulation and use electrical tape. I'm only asking as the only source I can find for that part is RS and they want £4.95 to ship a £1.05 component 🙁

I think Ralf is right about a continuity issue but before I run his suggested test I want to replace the R1 resistor I removed with one that's seen better days first as its reading ok but its heat damaged and there are some hairline cracks in the exterior coating.

You can do the test even without the R1 resistor in place. It is in parallel to a coil, so even if it isn't there the flow of current isn't blocked. What happens is only a small difference in the FR.

Ralf

Ralf

I am going to hang back for a day or so mainly because I bought the new speaker cable and the ceramic resistor from the same place

Stuart.

I am going to hang back for a day or so mainly because I bought the new speaker cable and the ceramic resistor from the same place

Stuart.

Its going to be longer than a day, I re-soldered and heat shrinked the connectors to the jones plug on the wiring loom, however when I was doing that I noticed just how bad the wiring was into the sub and tweeter, plus part of the wiring had spent the best part of 25+ years jammed in between the tweeter and the case. So I have had to order up some 14 gauge wire to replace the damaged parts.

As for the soldering, I'm fairly average, mainly because I don't get enough practice but if I had done joints that badly ever, my old gaffer would have turned the air blue and referenced "minkies".

As for the soldering, I'm fairly average, mainly because I don't get enough practice but if I had done joints that badly ever, my old gaffer would have turned the air blue and referenced "minkies".

An externally hosted image should be here but it was not working when we last tested it.

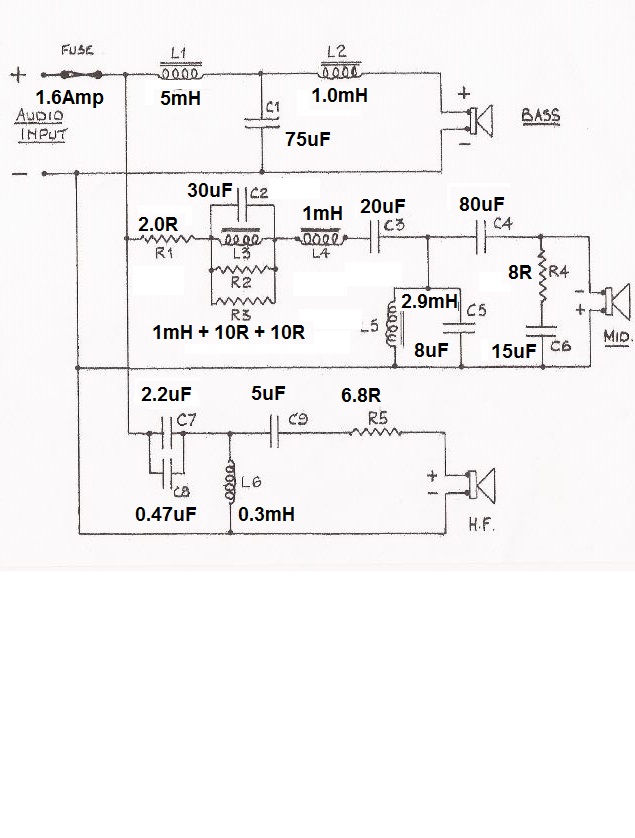

IIRC, the Bowers and Wilkins DM2A looked like this:

Bextrene bass, Celestion HF1300 tweeter and Coles 4001G supertweeter.

I even remember the crossover:

Hope it helps.

Bextrene bass, Celestion HF1300 tweeter and Coles 4001G supertweeter.

I even remember the crossover:

Hope it helps.

Steve, thanks for the reply, really useful and that is the beastie (apart from my cabinet is white).

Would you by any chance know what I should replace the thin approx. 4mm foam that was over the rear of the frame on the Bextrene bass with? Its turned to dust over the years and I am going to have to drop it out anyway just to clean up the bits so I might as well replace it at the same time.

Would you by any chance know what I should replace the thin approx. 4mm foam that was over the rear of the frame on the Bextrene bass with? Its turned to dust over the years and I am going to have to drop it out anyway just to clean up the bits so I might as well replace it at the same time.

I would guess what you are looking for is Eggbox Profile Foam Laminate:

Eggbox Profile Foam Laminate Panel

Standard component in 1/8 wavelength reflex speakers. 🙂

Eggbox Profile Foam Laminate Panel

Standard component in 1/8 wavelength reflex speakers. 🙂

Steve

Sorry, that's not it, I have attached a photo if it helps, its very degraded though, I measured it to 4mm though I suspect it started out as 5mm or 6mm from searching online suppliers. All the foam descriptions say for front grill use but I think its the same stuff.

My issue is that its pretty flimsy stuff and would I be better going for a greater thickness / different material, or just cleaning out the degraded material and not replacing it as a couple of online sources I read say that it was only speakers in the 70's & 80's that had this and its not used on more modern speakers?

Sorry, that's not it, I have attached a photo if it helps, its very degraded though, I measured it to 4mm though I suspect it started out as 5mm or 6mm from searching online suppliers. All the foam descriptions say for front grill use but I think its the same stuff.

My issue is that its pretty flimsy stuff and would I be better going for a greater thickness / different material, or just cleaning out the degraded material and not replacing it as a couple of online sources I read say that it was only speakers in the 70's & 80's that had this and its not used on more modern speakers?

Whatever that is, it doesn't look as though it does much... 🙂

I like sticking felt or sound deadening material to side walls:

This is an old Spendor:

People use BAF wadding too. Make it up as you go along, I think.

This is a builders sound deadening corky/rubbery material called Regupol. Good stuff. I used carpet adhesive.

I like sticking felt or sound deadening material to side walls:

This is an old Spendor:

People use BAF wadding too. Make it up as you go along, I think.

This is a builders sound deadening corky/rubbery material called Regupol. Good stuff. I used carpet adhesive.

- Home

- Loudspeakers

- Multi-Way

- B&W DM2A Speakers