Hi All

I am building the slim design from Mark Audios homepage:

CHP 70 Natural | Markaudio

I am doing the woodwork now, but I was wondering about damping for this enclosure. There is no info in the plans, and I can't seem to find any online either.

I expect that damping should be added to all speaker enclosures (at least standard ones from standard materials) to avoid standing waves and strong reflections, but I am unsure as to how much and where?

I have the "eggshell"-type that I expect to use for the internal walls, and some "loose stuffing" to put inside the enclosure as well.

My questions are:

*How much eggshell type should I use? - i.e. should the eggshell-type be applied to all walls, or just one side of each parallel wall set (e.g. back wall + 1 side wall + top or bottom)?

*Should I also put eggshell-type on the front baffle?

*how much loose stuffing should I add?

I know that it is a "trial and error"-process, but I have no clue as to appropriate amounts - thus I would like to get it in the right ball park from the beginning...

thank you for all your help!

/BR

Jakob

I am building the slim design from Mark Audios homepage:

CHP 70 Natural | Markaudio

I am doing the woodwork now, but I was wondering about damping for this enclosure. There is no info in the plans, and I can't seem to find any online either.

I expect that damping should be added to all speaker enclosures (at least standard ones from standard materials) to avoid standing waves and strong reflections, but I am unsure as to how much and where?

I have the "eggshell"-type that I expect to use for the internal walls, and some "loose stuffing" to put inside the enclosure as well.

My questions are:

*How much eggshell type should I use? - i.e. should the eggshell-type be applied to all walls, or just one side of each parallel wall set (e.g. back wall + 1 side wall + top or bottom)?

*Should I also put eggshell-type on the front baffle?

*how much loose stuffing should I add?

I know that it is a "trial and error"-process, but I have no clue as to appropriate amounts - thus I would like to get it in the right ball park from the beginning...

thank you for all your help!

/BR

Jakob

Jakob,

Are you building a single driver system? Then maybe ask the mods to transfer your thread to the Full-range forum?

On you question on lining internal walls - the cabinet you are planning to build is bass-reflex (BR) cabinet. For BR cabinets, lining the inside cabinet walls with felt material is quite popular among full-range driver enthusiasts, 10-12 mm of wool felt type material should work. This type of felt can be found as wool carpet underlay.

Regarding application it should be on insides of both the side-walls, inside of top, inside of bottom panel, and inside of back panel.

Are you building a single driver system? Then maybe ask the mods to transfer your thread to the Full-range forum?

On you question on lining internal walls - the cabinet you are planning to build is bass-reflex (BR) cabinet. For BR cabinets, lining the inside cabinet walls with felt material is quite popular among full-range driver enthusiasts, 10-12 mm of wool felt type material should work. This type of felt can be found as wool carpet underlay.

Regarding application it should be on insides of both the side-walls, inside of top, inside of bottom panel, and inside of back panel.

Hi zman01

Thank you for the feedback!

Yes it is a full-range speaker - but as the question pertained to the cabinet I thought I would put it here...can a moderator please move it if it will receive more attention in the full-range forum?

Regarding the felt material, I have already purchased the eggshell-type found here:

https://bekent.dk/hojtalerskum-aeggebakke-mdm-40.html

As it is listed as "suitable for bass reflex type speakers".

But if felt is indeed better I will buy some?

And if I understand you correctly, it should cover all internal surface except the front?

And how about loose stuffing?

I have this:

https://bekent.dk/daempemateriale-polyester-mdm-2.html

Or do I not need any for this cabinet type?

Thank you for any feedback!

BR

Jakob

Thank you for the feedback!

Yes it is a full-range speaker - but as the question pertained to the cabinet I thought I would put it here...can a moderator please move it if it will receive more attention in the full-range forum?

Regarding the felt material, I have already purchased the eggshell-type found here:

https://bekent.dk/hojtalerskum-aeggebakke-mdm-40.html

As it is listed as "suitable for bass reflex type speakers".

But if felt is indeed better I will buy some?

And if I understand you correctly, it should cover all internal surface except the front?

And how about loose stuffing?

I have this:

https://bekent.dk/daempemateriale-polyester-mdm-2.html

Or do I not need any for this cabinet type?

Thank you for any feedback!

BR

Jakob

Hi Jakob,

Since you have already got the lining materials, then maybe use them first?

Are you making a removable back panel (or front baffle)? If there is a removable panel, it will be possible for you to take out the existing lining and install some other type of material later if you want to.

So you can try with the egg-crate type and then with the polyester lining and hear the difference if any.

Yes, all internal surfaces except the front.

Since you have already got the lining materials, then maybe use them first?

Are you making a removable back panel (or front baffle)? If there is a removable panel, it will be possible for you to take out the existing lining and install some other type of material later if you want to.

So you can try with the egg-crate type and then with the polyester lining and hear the difference if any.

Yes, all internal surfaces except the front.

Grr can't post because token expired :-/

I'll make it brief:

Zman: I'm not planning on a removable back/baffle, as it is to much hassle for me (time is at a premium with 3 small kids )

)

Lojzek: thanks for the link - interesting reading... But the way I read it, they are suggesting I use foam+fibres, which is exactly what I had planned?

Their point on fibre density is also great, but I'm not sure how close to the driver/port I should stuff it?

BR

Jakob

I'll make it brief:

Zman: I'm not planning on a removable back/baffle, as it is to much hassle for me (time is at a premium with 3 small kids

Lojzek: thanks for the link - interesting reading... But the way I read it, they are suggesting I use foam+fibres, which is exactly what I had planned?

Their point on fibre density is also great, but I'm not sure how close to the driver/port I should stuff it?

BR

Jakob

Grr can't post because token expired :-/

For that, just copy the reply to the clipboard (works also on a tablet etc.) before sending. If it fails, just hit 'reply' again and paste it. Voilà.

Lojzek: thanks for the link - interesting reading... But the way I read it, they are suggesting I use foam+fibres, which is exactly what I had planned?

Their point on fibre density is also great, but I'm not sure how close to the driver/port I should stuff it?

The port has to be free, you need to leave out an empty 'sphere' around it. You should leave also space around the driver. If you don't, the damping material around the port eats up a lot of bass. If there's too much mid-crap comming out of the port (not likely at this speaker), put the port on the back of the box.

YW  If you run into any problems, just ask.

If you run into any problems, just ask.

You don't have to glue on the foam, at small enclosures it usually stays in place on its own if you don't cut it too small. For many enclosures it works great if you cut one sheet to one U-form shape in the inner dimensions of the box. For your CHP 70 slim around ~45cm in length (dimensions minus the thickness (curves/edges make it shorter) and the height of ~28cm. Then top and bottom. That got several advantages, it goes fast, you keep the pieces big for future projects, you can take it out again easily (if you decide it's too much, want another enclosure or use it in another project) and you avoid too many small pieces which could wander around, blocking the port or find a way into the basket of the driver. For the port and terminals it's often enough if you cut a slit in it and stretch it out over them. Still reusable, fast to do with very little effort.

Keep the driver (air movement) and crossover clear, especally the resistors, they will get hot and could melt or burn the damping material.

You don't have to glue on the foam, at small enclosures it usually stays in place on its own if you don't cut it too small. For many enclosures it works great if you cut one sheet to one U-form shape in the inner dimensions of the box. For your CHP 70 slim around ~45cm in length (dimensions minus the thickness (curves/edges make it shorter) and the height of ~28cm. Then top and bottom. That got several advantages, it goes fast, you keep the pieces big for future projects, you can take it out again easily (if you decide it's too much, want another enclosure or use it in another project) and you avoid too many small pieces which could wander around, blocking the port or find a way into the basket of the driver. For the port and terminals it's often enough if you cut a slit in it and stretch it out over them. Still reusable, fast to do with very little effort.

Keep the driver (air movement) and crossover clear, especally the resistors, they will get hot and could melt or burn the damping material.

Since it's a project using a single wide-band driver, it is likely that there will be no cross-over circuit.

Since most wide band drivers aren't super linear and you have to correct the baffle step also on a WB system, most of them indeed DO need filtering. Some are acceptable without, the majority profits a lot of them.

ICG and Zman

Thank you for more valuable input

Zman is indeed correct - no crossover in this project (driver doesn't have any nasties requiring equalization )

)

But now I get a little confused again - you talk about putting foam around the port, but I understood that I should not add anything to the front baffle? - were you thinking of rear ported enclosures?

BR

Jakob

Thank you for more valuable input

Zman is indeed correct - no crossover in this project (driver doesn't have any nasties requiring equalization

But now I get a little confused again - you talk about putting foam around the port, but I understood that I should not add anything to the front baffle? - were you thinking of rear ported enclosures?

BR

Jakob

Thanks, Lojzek!

The baffle step isn't something the driver comes with, it comes with the enclosure. It is directly dependent on the width of the baffle (=front) and no matter how good (or bad) the driver is, it still applies, the driver can't 'switch it off'. The baffle step is a rise in the response towards higher frequencies, caused by the reflection on the edges. If the driver is linear in the measurement baffle (usually very big, ~2m) of the datasheet, then it's not in the box with a much smaller baffle.

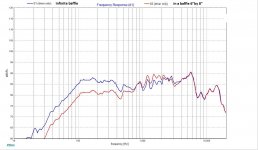

Lojzek already showed it, here is another example (with filter): Markaudio CHR-70 8Liter monitor - forum.zelfbouwaudio.nl

It is the CHR-70 but in that regard they behave the same. You can also compare the measurement there with the datasheet and you can see there significant differences. Don't worry, the CHP-70 is a good driver and you'll probably like it but you should at least experiment with a filter to find out if you're not leaving out potential.

I just didn't mention it (because I forgot, lol!). You can or even should also add some there but the surface isn't very large, because the driver takes up a lot, so the difference is not very big though. It is not good to over-stuff the box and you have to snip and snap the most on the front so I often do that last because it 'destroys' the most of the foam, to re-use it is sometimes not that great. How much is 'right' depends on the box, the room (placement of the speakers is very important, also for depth and room perception!) and ofcourse the own taste. You can remove or add more of it at any time if you don't like the sound. Remove some if it's too 'slim' in the bass and lower mids, starting with the "loose stuffing", after that the front foam.

If it sounds hollow or bucket-ish it's likely not enough. If the mids are too 'present' or too direct, then don't over-dampen it (that will remove the bass), experiment then with a filter.

I'd start with the foam alone, as I said, you can change it anytime unless you glue it in place.

Standing waves aren't much of an issue with a that small enclosure, at these frequencies the damping is quite effective.

Zman is indeed correct - no crossover in this project (driver doesn't have any nasties requiring equalization)

The baffle step isn't something the driver comes with, it comes with the enclosure. It is directly dependent on the width of the baffle (=front) and no matter how good (or bad) the driver is, it still applies, the driver can't 'switch it off'. The baffle step is a rise in the response towards higher frequencies, caused by the reflection on the edges. If the driver is linear in the measurement baffle (usually very big, ~2m) of the datasheet, then it's not in the box with a much smaller baffle.

Lojzek already showed it, here is another example (with filter): Markaudio CHR-70 8Liter monitor - forum.zelfbouwaudio.nl

It is the CHR-70 but in that regard they behave the same. You can also compare the measurement there with the datasheet and you can see there significant differences. Don't worry, the CHP-70 is a good driver and you'll probably like it but you should at least experiment with a filter to find out if you're not leaving out potential.

But now I get a little confused again - you talk about putting foam around the port, but I understood that I should not add anything to the front baffle?

I just didn't mention it (because I forgot, lol!). You can or even should also add some there but the surface isn't very large, because the driver takes up a lot, so the difference is not very big though. It is not good to over-stuff the box and you have to snip and snap the most on the front so I often do that last because it 'destroys' the most of the foam, to re-use it is sometimes not that great. How much is 'right' depends on the box, the room (placement of the speakers is very important, also for depth and room perception!) and ofcourse the own taste. You can remove or add more of it at any time if you don't like the sound. Remove some if it's too 'slim' in the bass and lower mids, starting with the "loose stuffing", after that the front foam.

If it sounds hollow or bucket-ish it's likely not enough. If the mids are too 'present' or too direct, then don't over-dampen it (that will remove the bass), experiment then with a filter.

I'd start with the foam alone, as I said, you can change it anytime unless you glue it in place.

Standing waves aren't much of an issue with a that small enclosure, at these frequencies the damping is quite effective.

Hi All

More input - great

regarding baffle step compensation; these speakers will be on near-field duty (desktop at work), from what I understand this (at least partly) compensates the need for a baffle step compensation? (though I don't get this, I would expect near field to require more compensation as the bass is not enhanced by surfaces nearby?)

And I will stuff the front also...

I am also seriously considering making the rear side of the cabinet removable...I don't want to only have access through the relatively small hole for the driver...

thank you all!

BR

Jakob

More input - great

regarding baffle step compensation; these speakers will be on near-field duty (desktop at work), from what I understand this (at least partly) compensates the need for a baffle step compensation? (though I don't get this, I would expect near field to require more compensation as the bass is not enhanced by surfaces nearby?)

And I will stuff the front also...

I am also seriously considering making the rear side of the cabinet removable...I don't want to only have access through the relatively small hole for the driver...

thank you all!

BR

Jakob

Hi All

More input - great

regarding baffle step compensation; these speakers will be on near-field duty (desktop at work), from what I understand this (at least partly) compensates the need for a baffle step compensation? (though I don't get this, I would expect near field to require more compensation as the bass is not enhanced by surfaces nearby?)

No, it will get worse. And much less predictable. You'll get an even bigger hunch in the midrange because not only the side edges will have an effect, the complete reflections from the surroundings and the desk are present, that's then definitely something you'll need a filter for. I'm sorry, too much to explain right now for me. Get the baffle step calculator 'EDGE' and try for yourself. You don't have to compensate that exactly, the simulated compensation of the program can be made much simpler. Or, even much simpler than that, you could use the EQ on the computer, with a wide band driver that can be a good solution.

Thank you - makes sense. All the more reason to make the rear removable...

Your point on using the eq on the computer is a good one, though I will need a traditional compensation at some point, as I also listen to CD and vinyl at work

But starting with the computer will also allow me to figure out what effect I need from the circuit-based compensation before I actually build it...

I may even bring my DEQ2496 from home just to see the actual in-room response...

TY!

BR Jakob

Your point on using the eq on the computer is a good one, though I will need a traditional compensation at some point, as I also listen to CD and vinyl at work

But starting with the computer will also allow me to figure out what effect I need from the circuit-based compensation before I actually build it...

I may even bring my DEQ2496 from home just to see the actual in-room response...

TY!

BR Jakob

Thank you - makes sense. All the more reason to make the rear removable...

No, it's not. You can do everything exactly the same, change the dampening through the opening of the driver. And don't make yourself the life in any way harder than needed. You simply experiment with the filter on the OUTSIDE of the box, no need to open and close it, it's just one driver, put it in one of the input wires, or to be more precise, between one of your speaker wire and the terminal.

Your point on using the eq on the computer is a good one, though I will need a traditional compensation at some point, as I also listen to CD and vinyl at work

[...]

But starting with the computer will also allow me to figure out what effect I need from the circuit-based compensation before I actually build it...

Instead of inflicting so much pain on yourself by changing the parts over and over again to do that, I strongly suggest you first find out with your EQ and different placements of the speakers what has to be done. And you will have to modify it a lot, the sound changes a LOT on these short distances since the angles very much with just little movement. Placement is extremely important. I'd also try to get them away from the desk plate, at such a setup even a few cm are changing very much. And don't forget to change the angle of the speakers too (horizontally and vertically too). And take your time to listen to them, what sounds great and right at first can be annoying in the long run. Or there are colourations you do not notice until you change the music material.

Besides that, you can play the CDs also from your computer, either with the CD drive or with reading them out and playing them the same way as any other tracks on the computer. If you use FLAC, it's lossless, so no reason there.

I may even bring my DEQ2496 from home just to see the actual in-room response...

You can do that and the parametric EQs are excellent for rebuilding the filters later in actual parts. However, the auto-EQ of the Behringer DEQ2496 does not help you there at all. There are numerous reasons for that. it does not create parametric EQs, it corrects on way too many (fixed) bands with way too steep slopes to rebuild that in parts, it only optimizes it to one single point in the room (where the measurement mic is) and that can change a lot with the position at such short distances. And the most important thing is, the auto-EQ lowers and boosts frequencies. Boosting something is just not possible passive, you can only reduce the level.

The mightier the tool, the more precise you have to know what you're doing and - even more important - what you must not do.

My reason for doing the removable rear panel rather than the driver, is that I am not too sure about putting T-nuts on the relatively narrow lip available for driver mounting. This leaves me with standard wood-screws for the drivers - and I'm afraid I'll strip the wood over time... also, the entry hole is quite small when removing the driver (I don't have small handsNo, it's not. You can do everything exactly the same, change the dampening through the opening of the driver. And don't make yourself the life in any way harder than needed. You simply experiment with the filter on the OUTSIDE of the box, no need to open and close it, it's just one driver, put it in one of the input wires, or to be more precise, between one of your speaker wire and the terminal.

I was planning on making a couple of small stands to place them about 8cm above the table. I will either make the angle adjustable, or use something else until I know the correct tilt angle for them...and good point about the varying music - will make sure to try all sorts..Instead of inflicting so much pain on yourself by changing the parts over and over again to do that, I strongly suggest you first find out with your EQ and different placements of the speakers what has to be done. And you will have to modify it a lot, the sound changes a LOT on these short distances since the angles very much with just little movement. Placement is extremely important. I'd also try to get them away from the desk plate, at such a setup even a few cm are changing very much. And don't forget to change the angle of the speakers too (horizontally and vertically too). And take your time to listen to them, what sounds great and right at first can be annoying in the long run. Or there are colourations you do not notice until you change the music material.

I have pretty much all my music in FLAC, but sometimes it's just nice to have the CD available - e.g. if I have left my computer in the lab, or I am reading articles with the computer off etc.Besides that, you can play the CDs also from your computer, either with the CD drive or with reading them out and playing them the same way as any other tracks on the computer. If you use FLAC, it's lossless, so no reason there.

Also, my vinyl would still be a problem

EDIT: and my computer doesn't have a CD-drive (only have an external drive lying around, which sound like a boeing taking off).

Sure, wasn't planning on using the Auto-eq - I only use it as a guide to apply the parametric EQs like this guy:You can do that and the parametric EQs are excellent for rebuilding the filters later in actual parts. However, the auto-EQ of the Behringer DEQ2496 does not help you there at all. There are numerous reasons for that. it does not create parametric EQs, it corrects on way too many (fixed) bands with way too steep slopes to rebuild that in parts, it only optimizes it to one single point in the room (where the measurement mic is) and that can change a lot with the position at such short distances. And the most important thing is, the auto-EQ lowers and boosts frequencies. Boosting something is just not possible passive, you can only reduce the level.

The mightier the tool, the more precise you have to know what you're doing and - even more important - what you must not do.

A comprehensive illustrated guide to using the Behringer DEQ2496 optimally in a domestic hi-fi system.

Also, is there some software/hardware that can use the Behringer microphone for a "pure" response curve (that isn't too expensive)?

TY!

BR Jakob

Last edited:

Jakob,

There is no harm making a back panel - little bit of extra work, yes. But since this is you want to (might need to) experiment with the lining, you might as well go for it. One other risk with taking out the driver is damaging it by accident (slip of screw, Allen key driver).

The CHP-70 should come with screws supplied - those would be 4 hex head screws for each driver.

There is no harm making a back panel - little bit of extra work, yes. But since this is you want to (might need to) experiment with the lining, you might as well go for it. One other risk with taking out the driver is damaging it by accident (slip of screw, Allen key driver).

The CHP-70 should come with screws supplied - those would be 4 hex head screws for each driver.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Damping material for Mark Audio CHP-70 slim design