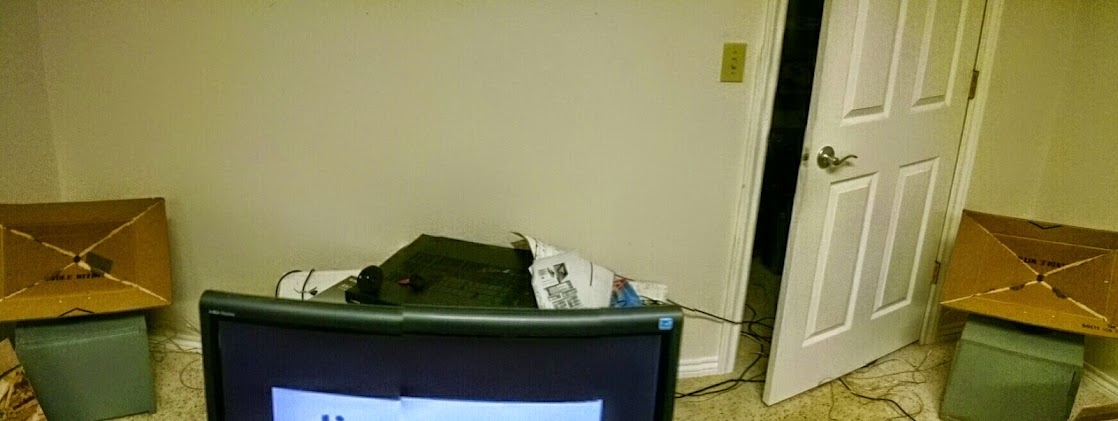

Made from cardboard, glued together with Gorilla glue.

Using Bill Waslo's spreadsheet. The only thing I changed was the throat size for the compression drivers I have.

Drivers = Eminence Alpha 8a, Pyle PDS521.

So far, sounds good, but needs some minor tweaking. The left compression driver sounds quieter at the moment, but that might be poor wiring.

AV receiver is doing the EQ for each driver.

I will also paint and finish them, and make a 16 litre box for the Alpha 8a.

Nice! Foam Core would work better next time.

What was the design horn frequency and angles? You will have cardboard wall vibrations that will reduce the sensitivity and add harmonic distortion. Use latex caulking liberally to act as damping material and put on second layer of cardboard. You will gain about 6 to 9dB in spl and reduce HD by 10 to 15dB. Big changes for a little more work. The absorber panels can be smaller than real horn wall panels and be rough cut.

What was the design horn frequency and angles? You will have cardboard wall vibrations that will reduce the sensitivity and add harmonic distortion. Use latex caulking liberally to act as damping material and put on second layer of cardboard. You will gain about 6 to 9dB in spl and reduce HD by 10 to 15dB. Big changes for a little more work. The absorber panels can be smaller than real horn wall panels and be rough cut.

Thanks X. I was thinking of doing a ribbing-style of brace system, but yes, I'll get some caulk and add some constrained layer damping.

The reason I say that it's not correct is because it's only two drivers. But, recently I've been lost in the maths. I'm using my ears again, and they are pleasant and accurate.

Another reason for cardboard was that I had numerous boxes with folds, and so where the second stage of the horn starts, the fold would exist there. It saved on gluing 8 main panels, only 4.

I had a quick look at the spreadsheet, and I left everything default except for the size of the throat...0.972 inches (1.375" * 0.707). Probably wrong.

I'll try foam core next time. The bandsaw did a good job, and I essentially cut everything in one pass from two templates by stacking the cardboard up.

The reason I say that it's not correct is because it's only two drivers. But, recently I've been lost in the maths. I'm using my ears again, and they are pleasant and accurate.

Another reason for cardboard was that I had numerous boxes with folds, and so where the second stage of the horn starts, the fold would exist there. It saved on gluing 8 main panels, only 4.

I had a quick look at the spreadsheet, and I left everything default except for the size of the throat...0.972 inches (1.375" * 0.707). Probably wrong.

I'll try foam core next time. The bandsaw did a good job, and I essentially cut everything in one pass from two templates by stacking the cardboard up.

To add to that, I've found that having a stereo pair makes all the difference. Even with the 90 degree horizontal dispersion pattern, panning positions at naturally obvious. Anything in a mix that isn't panned blends together from both sources very evenly. I feel like I'm listening to an expensive pair of speakers in a well-treated room.

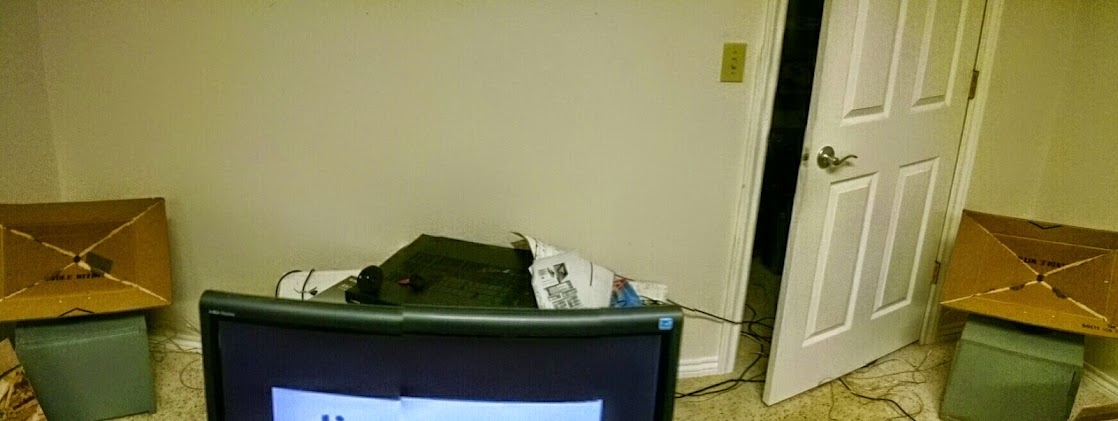

The picture shows otherwise...

X, I think I'm going to make a pair that have pattern control to 250Hz, but maybe with a 60x45 (w x h) pattern, so I get more of the sound at my listening position (and not going where it's not needed).

I'll fiddle with Bill's spreadsheet tomorrow, but I had one question for you: does PVA glue work with foam core board? The gorilla glue is quite quick, and allows me to work inside (hence the speed), but it's probably overkill...

The picture shows otherwise...

X, I think I'm going to make a pair that have pattern control to 250Hz, but maybe with a 60x45 (w x h) pattern, so I get more of the sound at my listening position (and not going where it's not needed).

I'll fiddle with Bill's spreadsheet tomorrow, but I had one question for you: does PVA glue work with foam core board? The gorilla glue is quite quick, and allows me to work inside (hence the speed), but it's probably overkill...

It also could be the left driver, cheap HF drivers often are inconsistent from unit to unit.Drivers = Eminence Alpha 8a, Pyle PDS521.

So far, sounds good, but needs some minor tweaking. The left compression driver sounds quieter at the moment, but that might be poor wiring.

If you swap them you will find whether the difference is due to "poor wiring" or crappy driver quality control.

Ok. I just wanted to make sure as I've tried another type of glue that refused to stick to the surface...or the foam inside.

Well, that HF problem has gone away. I ran the auto calibration procedure on my receiver, and now everything is even. I think it had to tame the Alpha 8a channels a bit, as they were very 'present'.

Measurement-wise, RTA on my phone doesn't show much, except that the frequency response is relatively level. It's also interesting to see how 'lively' dynamically the mid range in music is!

Well, that HF problem has gone away. I ran the auto calibration procedure on my receiver, and now everything is even. I think it had to tame the Alpha 8a channels a bit, as they were very 'present'.

Measurement-wise, RTA on my phone doesn't show much, except that the frequency response is relatively level. It's also interesting to see how 'lively' dynamically the mid range in music is!

Made from cardboard, glued together with Gorilla glue.

Using Bill Waslo's spreadsheet. The only thing I changed was the throat size for the compression drivers I have.

Drivers = Eminence Alpha 8a, Pyle PDS521.

So far, sounds good, but needs some minor tweaking. The left compression driver sounds quieter at the moment, but that might be poor wiring.

AV receiver is doing the EQ for each driver.

I will also paint and finish them, and make a 16 litre box for the Alpha 8a.

I don't know how to weld. For my bike I needed a material that was strong and light. I used cardboard. Admittedly, it's wrapped in fiberglass. But an inch of cardboard, sandwiched between two layers of glass, is quite strong.

Something tells me that to ride that bike you need to take more of a gyroscopic approach like you would on a motorcycle (which I've not experienced first-hand), but that's a nice design Patrick!

I remember your experiments with Jute twine and Gorilla glue when you were making the Le Cleac'h Synergy horn, and I did think about using burlap sheets or strips for making a horn in a papier mache approach, but haven't really needed it yet.

The two-stage horn makes for a strong design in itself. They've taken some abuse while I've been putting them together, and even with cardboard they hardly move or twist.

Still, masonite/hardboard might be a stronger alternative. As with any thinner walls, they can always be braced or damped at a later stage.

I did hear some ringing today, when I had a chance to test them at volume, but that was to be expected.

I remember your experiments with Jute twine and Gorilla glue when you were making the Le Cleac'h Synergy horn, and I did think about using burlap sheets or strips for making a horn in a papier mache approach, but haven't really needed it yet.

The two-stage horn makes for a strong design in itself. They've taken some abuse while I've been putting them together, and even with cardboard they hardly move or twist.

Still, masonite/hardboard might be a stronger alternative. As with any thinner walls, they can always be braced or damped at a later stage.

I did hear some ringing today, when I had a chance to test them at volume, but that was to be expected.

I've been fiddling a little with Bill's spreadsheet, and it seems that there are diminishing returns past a certain point. A few things I need to remember:

* The low end response of the horn does not necessarily relate to the horn's size

* Smaller dispersion angles lead to a bigger horn

It really does look like the dimensions Bill used for the CoSyne are the 'sweet spot'. I don't want to say 'best compromise' or 'middle ground', because that would suggest a negative approach.

I am going to make the horns bigger though, but solely for the reason that I'll be able to fit the Alpha 8a onto a single panel

xrk971 - my wife went to a craft shop yesterday, and picked up two bags of hot melt glue, so I'm hopeful that'll speed things up!

* The low end response of the horn does not necessarily relate to the horn's size

* Smaller dispersion angles lead to a bigger horn

It really does look like the dimensions Bill used for the CoSyne are the 'sweet spot'. I don't want to say 'best compromise' or 'middle ground', because that would suggest a negative approach.

I am going to make the horns bigger though, but solely for the reason that I'll be able to fit the Alpha 8a onto a single panel

xrk971 - my wife went to a craft shop yesterday, and picked up two bags of hot melt glue, so I'm hopeful that'll speed things up!

wow, a front wheel drive bike! How does it handle?

That's the key. Because the geometry is 100% road bike, it handles like a road bike. The exception to the rule is the torque steer introduced by pedaling.

But I better keep things on topic! If you're curious, check out the homebuilders forum at bentrideronline

Yeah, it's kind of amazing how good even a rough build of a Synergy can sound. I haven't built with foamboard or cardboard, but I bet the cone vibration isn't as bad as we might think. After all, the masses off the moving diaphragm aren't much and they don't have to move very much either because of the horn. So the reaction force from the cones can't be large against the heavy drivers. And the rest is just air.

I keep thinking that Tom might not realize what he has with these as home speakers.

I keep thinking that Tom might not realize what he has with these as home speakers.

I agree Bill, and the 'ringing' I hear might be false too; certainly, the vibration of the horn when music is running through them is minimal, if any.

It's a testament to your calculator too, because your hard work has made it quite easy! I would like to make a faithful pair of the CoSynes at some point.

Tom has certainly also made a design that really works in the home. If only the Paraline could, but we can only go as far as physics will let us!

It's a testament to your calculator too, because your hard work has made it quite easy! I would like to make a faithful pair of the CoSynes at some point.

Tom has certainly also made a design that really works in the home. If only the Paraline could, but we can only go as far as physics will let us!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- An incorrect way to do a Synergy horn