This afternoon I've been refining the horn in one of my projects*.

I've been doing some measurements as I go, so I thought I'd document the improvements.

Some of this information will repeat from my 'Homster**' thread, so apologies in advance for the redundancy.

The first thing is to put a resistor in series with the compression driver. This does a few things. First, it lowers the noise level. In my setup, with a miniDSP, there was an audible hiss. This is because the compression driver has an efficiency of 109dB. So it's like an Xray for noisy components upstream. On my system, the 10ohm resistor dropped the output of the compression driver by approximately 8.5dB.

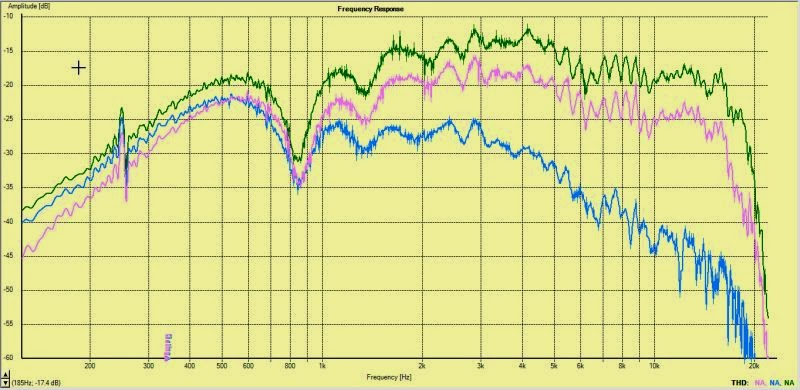

In the pics above, I have four measurements. From the top to bottom we have the speaker with no resistor, we have the speaker with a 10ohm resistor in series with the compression driver. Then I repeat the process but I adjusted the output of the compression driver to match the midrange, now with the resistor in series. The difference in noise level was startling.

The second thing that the resistor does is to increase output in the bottom octave of it's response, and in the top end. This is particularly nice since it's challenging to get a lot of output from a compression driver in the octave from 10khz to 20khz. (Due to the driver's mass rolloff.)

Here's how this works: Like most speakers, a compression driver has a rise in impedance at resonance, and due to inductance. When you put a resistor in series, it affects the frequency response *less* at resonance and in the top octave of it's response. (Due to inductance.) For instance the resistor drops output at 2khz by 6dB, but by 8.5dB at 5khz and at 10khz. So once you compensate for the reduction by increasing the voltage to the compression driver, you now have a bit of 'boost' at resonance and in the top octave. (Because the resistor's impact varies by frequency.)

Last but not least, the resistor linearizes the impedance curve to a degree, like a cheap version of a zobel filter, which makes any passive components work closer to 'textbook' values. For instance, if you put a capacitor in series with a compression driver, the affect of the capacitor will be small at the driver's resonance, due to the rise in impedance. But if you use a resistor to linearizes the impedance, then select a capacitor value that's appropriate for the higher overall impedance, the filter slope will be a closer match to the ideal value, be it Butterworth, Linkwitz Riley, etc...

On face value, it might seem like this tweak would reduce the output of the compression driver. But for the most part, it doesn't. The compression drivers power handling is still the same, just a fraction of that power is going into the resistor. And it's excursion is as high as ever. The only real downside is that it's a waste of power... But I probably use about five watts on my compression driver, if that, so the waste of power isn't a big deal to me.

If you want to read up further on this, check out some of the posts on 'LeCleach on Horns' where they discuss putting resistors in series. I broke out a new thread simply to document the results in my project.

More improvements coming up...

* http://www.diyaudio.com/forums/multi-way/252549-edge-no-control.html

** http://www.diyaudio.com/forums/multi-way/151376-homster-how-i-learned-how-fix-horn.html

I've been doing some measurements as I go, so I thought I'd document the improvements.

Some of this information will repeat from my 'Homster**' thread, so apologies in advance for the redundancy.

The first thing is to put a resistor in series with the compression driver. This does a few things. First, it lowers the noise level. In my setup, with a miniDSP, there was an audible hiss. This is because the compression driver has an efficiency of 109dB. So it's like an Xray for noisy components upstream. On my system, the 10ohm resistor dropped the output of the compression driver by approximately 8.5dB.

In the pics above, I have four measurements. From the top to bottom we have the speaker with no resistor, we have the speaker with a 10ohm resistor in series with the compression driver. Then I repeat the process but I adjusted the output of the compression driver to match the midrange, now with the resistor in series. The difference in noise level was startling.

The second thing that the resistor does is to increase output in the bottom octave of it's response, and in the top end. This is particularly nice since it's challenging to get a lot of output from a compression driver in the octave from 10khz to 20khz. (Due to the driver's mass rolloff.)

An externally hosted image should be here but it was not working when we last tested it.

Here's how this works: Like most speakers, a compression driver has a rise in impedance at resonance, and due to inductance. When you put a resistor in series, it affects the frequency response *less* at resonance and in the top octave of it's response. (Due to inductance.) For instance the resistor drops output at 2khz by 6dB, but by 8.5dB at 5khz and at 10khz. So once you compensate for the reduction by increasing the voltage to the compression driver, you now have a bit of 'boost' at resonance and in the top octave. (Because the resistor's impact varies by frequency.)

Last but not least, the resistor linearizes the impedance curve to a degree, like a cheap version of a zobel filter, which makes any passive components work closer to 'textbook' values. For instance, if you put a capacitor in series with a compression driver, the affect of the capacitor will be small at the driver's resonance, due to the rise in impedance. But if you use a resistor to linearizes the impedance, then select a capacitor value that's appropriate for the higher overall impedance, the filter slope will be a closer match to the ideal value, be it Butterworth, Linkwitz Riley, etc...

On face value, it might seem like this tweak would reduce the output of the compression driver. But for the most part, it doesn't. The compression drivers power handling is still the same, just a fraction of that power is going into the resistor. And it's excursion is as high as ever. The only real downside is that it's a waste of power... But I probably use about five watts on my compression driver, if that, so the waste of power isn't a big deal to me.

If you want to read up further on this, check out some of the posts on 'LeCleach on Horns' where they discuss putting resistors in series. I broke out a new thread simply to document the results in my project.

More improvements coming up...

* http://www.diyaudio.com/forums/multi-way/252549-edge-no-control.html

** http://www.diyaudio.com/forums/multi-way/151376-homster-how-i-learned-how-fix-horn.html

Last edited:

Here's a "neat" discovery that I made today:

Based on the work of Geddes*, I generally fill my horns and waveguides with foam. But cutting the foam is a p.i.t.a., so I generally use polyfill at first, and then I go to the effort of cutting the foam. I will also sometimes combine both; for instance I'll use polyfill in the throat, where it's hard to cut the foam perfectly due to the small size.

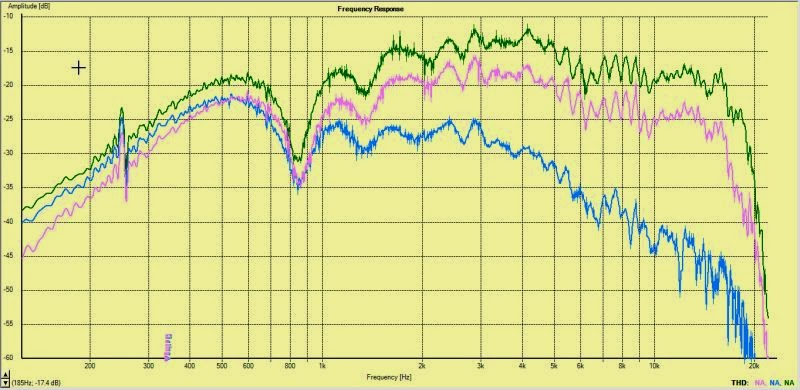

Today I used fiberglass instead of polyfill, based on some things that forum member Dave Smith wrote. ("Speakerdave".) Dave had mentioned that fiberglass attenuates sound more than other materials, and boy was he right. The graph above shows three sets of responses:

1) The horn's response with no stuffing (green)

2) The horn's response when filled with fiberglass (blue)

3) The horn's response when filled with a combination of both (pink)

It was quite interesting, because the fiberglass in particular really cleaned up the sound. Made it sound less like a compression driver and more like a dome tweeter. (HOM reduction?) Obviously, the problem with the fiberglass is that it's TOO effective; Even with my handy dandy miniDSP I was unable to EQ the horn to flat, because the fiberglass was wiping out 20dB of output in the top octave.

Subjectively, the greatest improvement was found by putting fiberglass in the throat of the horn. This offered the biggest 'bang for the buck.'

Based on that, I put reticulated foam right INTO the compression driver. Filled the phase plug, and in the sealed chamber of the driver. My B&C and JBL compression drivers have foam in the sealed chamber, so it couldn't hurt to put it in my Celestion CDX1-1425.

* Geddes on Waveguides

Based on the work of Geddes*, I generally fill my horns and waveguides with foam. But cutting the foam is a p.i.t.a., so I generally use polyfill at first, and then I go to the effort of cutting the foam. I will also sometimes combine both; for instance I'll use polyfill in the throat, where it's hard to cut the foam perfectly due to the small size.

Today I used fiberglass instead of polyfill, based on some things that forum member Dave Smith wrote. ("Speakerdave".) Dave had mentioned that fiberglass attenuates sound more than other materials, and boy was he right. The graph above shows three sets of responses:

1) The horn's response with no stuffing (green)

2) The horn's response when filled with fiberglass (blue)

3) The horn's response when filled with a combination of both (pink)

It was quite interesting, because the fiberglass in particular really cleaned up the sound. Made it sound less like a compression driver and more like a dome tweeter. (HOM reduction?) Obviously, the problem with the fiberglass is that it's TOO effective; Even with my handy dandy miniDSP I was unable to EQ the horn to flat, because the fiberglass was wiping out 20dB of output in the top octave.

Subjectively, the greatest improvement was found by putting fiberglass in the throat of the horn. This offered the biggest 'bang for the buck.'

Based on that, I put reticulated foam right INTO the compression driver. Filled the phase plug, and in the sealed chamber of the driver. My B&C and JBL compression drivers have foam in the sealed chamber, so it couldn't hurt to put it in my Celestion CDX1-1425.

* Geddes on Waveguides

I think you may want to reconsider this one.Last but not least, the resistor linearizes the impedance curve to a degree, like a cheap version of a zobel filter, which makes any passive components work closer to 'textbook' values. For instance, if you put a capacitor in series with a compression driver, the affect of the capacitor will be small at the driver's resonance, due to the rise in impedance. But if you use a resistor to linearizes the impedance, then select a capacitor value that's appropriate for the higher overall impedance, the filter slope will be a closer match to the ideal value, be it Butterworth, Linkwitz Riley, etc...

is it really safe to have foam sitting on top of the cone like that? I know it's light, but idk still seems like it would be too heavy for the tweeter cone.. I guess these do have really high pressure to deal with on a regular basis, just looks wrong to me.. I may try the fiberglass though.. Do some foam in the throat of the horn and then a light fiberglass fill right at the mouth

is it really safe to have foam sitting on top of the cone like that? I know it's light, but idk still seems like it would be too heavy for the tweeter cone.. I guess these do have really high pressure to deal with on a regular basis, just looks wrong to me.. I may try the fiberglass though.. Do some foam in the throat of the horn and then a light fiberglass fill right at the mouth

That's actually the sealed rear chamber of the tweeter. It's very tiny, a fraction of a liter. The CDX1-1425 is basically an aluminum dome tweeter with a phase plug. The diaphragm, phase plug, and voice coil are all one assembly.

The first thing is to put a resistor in series with the compression driver. This does a few things.

Patrick,

Why just a series resistor, instead of an L-pad?

Bill

Patrick,

Why just a series resistor, instead of an L-pad?

Bill

Model it in a crossover simulator or hornresp and you'll see the difference. Basically a series resistor will increase output in the top octave, which is very nice for compression drivers, since their output is declining in the top octave.

Jean Michael LeCleach used 30ohms iirc.

Yes the resistor in series Does work 🙂 I've done this many times over the years, both with Mid range horns & HF bullets when combining & matching them with a cone upper Bass / lower Mid in a 3 way passive box. A further neat trick, is to place the resistor after the xover, so the xover sees a higher overall resistance/impedance. This means you only need a lower value uf capacitor than if you placed the resistor before it = lower cost too 🙂

Hey Patrick,

What grade of foam do you use? I was going to try this in my JMLC 350Hz horn throat. I have found some stuff for pond filters- Does this sound right?

How do you shape it?

Do you line the horn with it, or fill it all up?

If I remember right, Dr Geddes suggests it reduces HOM?

What grade of foam do you use? I was going to try this in my JMLC 350Hz horn throat. I have found some stuff for pond filters- Does this sound right?

How do you shape it?

Do you line the horn with it, or fill it all up?

If I remember right, Dr Geddes suggests it reduces HOM?

I assume not all fiberglass is the same, is there a specific type most appropriate for this use? Thanks

That's the stuff. Make sure it has the right pore count. It feels spongy but you don't compress it, rather cut it to the shape you need. Earl uses a hot wire, scissors are good too. Waveguides are best filled, not lined.pond filters

Keep meaning to try this!

Which filter density are we looking for? (colour)

All Pond Solutions Replacement Pond Filter Foam Packs - Set of 3-17" x 11"; 25" x 18"; 36" x 24"; 42" x 21" (17" x 11"): Amazon.co.uk: Pet Supplies

Which filter density are we looking for? (colour)

All Pond Solutions Replacement Pond Filter Foam Packs - Set of 3-17" x 11"; 25" x 18"; 36" x 24"; 42" x 21" (17" x 11"): Amazon.co.uk: Pet Supplies

IIRC 20-30 PPI. I understand that standard aquarium filter mesh is a bit finer than that but has been used.

30 ppi open cell reticulated foam, here's some info : 30 PPI foam for HOM absorption in waveguides

It's much cheaper to buy it in bulk, the aquarium stuff is about 10X as costly.

Oddly enough, it's also the same foam that's used for recumbent bicycle seats, so you may find a link to buy it on those forums.

I buy mine from McMaster Carr, just bough a big roll for about $40. Enough for a lifetime of speakers.

It's much cheaper to buy it in bulk, the aquarium stuff is about 10X as costly.

Oddly enough, it's also the same foam that's used for recumbent bicycle seats, so you may find a link to buy it on those forums.

I buy mine from McMaster Carr, just bough a big roll for about $40. Enough for a lifetime of speakers.

The resistor should also reduce distortion. Another way of viewing it is moving the system from voltage driven to current driven (see Hawksford and Mills, twice, Pavel Macura, Rod Elliott, twice, and a few other references I can't find right now).

As an aside, I think this is a big part of what people like about tube and low feedback amps, the higher output impedance drives down higher order harmonics and IMD in the speakers, where you are actually likely to hear it. (Same could be said for horns and high efficiency speakers...)

As an aside, I think this is a big part of what people like about tube and low feedback amps, the higher output impedance drives down higher order harmonics and IMD in the speakers, where you are actually likely to hear it. (Same could be said for horns and high efficiency speakers...)

- Home

- Loudspeakers

- Multi-Way

- Cheap / Free Ways to Improve Your Horn