I am revisiting some of my older designs. This one is called T7-A7. The driver is an Alpair A7.3 It is a 4:1 tapered trasmision line folded up to be a stand mount satellite. I discovered through modeling that it made little difference to do a parallel panel manifold design or a constant taper design. Guess which is simpler to implement.

This redo is the first design that I did entirely with Pete Leonard's "Transmission Line" software rather than Martin King's MathCAD worksheets. Pete's software is built under Microsoft .NET Framework, so it will run under current Windows without any host software. It should work on a MAC with a curren Windows emulator, but that is another issue.

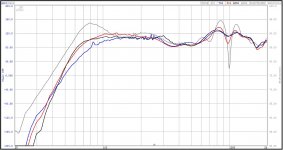

The issue I want to present here is stuffing vs lining the cabinet. The measurments were made at 0.5m, top end gated at 4.0ms and bottom at ~200-300Hz combined nearfield driver and port.

The gray line is the raw cabinet with no stuffing/lining. The overshoot seems excessive, but the dip at 1000Hz is real and predicted by the model. This is a feature of all TL's that has to be delt with. It is not present in a comparably tuned straight MLTL.

The red line is with the entire cabinet except the "port" stuffed with 2.0oz of WalMart polyfill. It appears that the real Dupont Hollowfil is not available in bulk, at least in DIY quartities. I have not brought myself to buy a $50-70 quilt just to salvage the stuffing. The blue line is 4.5oz of polyfill. Clearly too much. It kills too much bass, although it does an adequate job on the 1kHz feature.

The black line is a 5/8" lining of acoustic fiberglass. The back of the partition, the back of the cabinet, the top and bottom of the front chamber are lined. The fiberglass that I use is from Armstrong #420 cieling tiles with the plastic facing removed. Unfortunately, these panels are only available in boxes of 16 2'x4' panels for $100. Probably a bit steep for a single pair of small monitors, but I us quit a lot of it and the price is then not bad. ATS has single 1"x2'x4' panels for $7.50.

I think that the fiberglass panels clearly work better that cheap polyfill. No extrapolation to other materials. I do have the remains of a 16"x3" rockwool bat that I used to stuff a pair of subs.

Bob

This redo is the first design that I did entirely with Pete Leonard's "Transmission Line" software rather than Martin King's MathCAD worksheets. Pete's software is built under Microsoft .NET Framework, so it will run under current Windows without any host software. It should work on a MAC with a curren Windows emulator, but that is another issue.

The issue I want to present here is stuffing vs lining the cabinet. The measurments were made at 0.5m, top end gated at 4.0ms and bottom at ~200-300Hz combined nearfield driver and port.

The gray line is the raw cabinet with no stuffing/lining. The overshoot seems excessive, but the dip at 1000Hz is real and predicted by the model. This is a feature of all TL's that has to be delt with. It is not present in a comparably tuned straight MLTL.

The red line is with the entire cabinet except the "port" stuffed with 2.0oz of WalMart polyfill. It appears that the real Dupont Hollowfil is not available in bulk, at least in DIY quartities. I have not brought myself to buy a $50-70 quilt just to salvage the stuffing. The blue line is 4.5oz of polyfill. Clearly too much. It kills too much bass, although it does an adequate job on the 1kHz feature.

The black line is a 5/8" lining of acoustic fiberglass. The back of the partition, the back of the cabinet, the top and bottom of the front chamber are lined. The fiberglass that I use is from Armstrong #420 cieling tiles with the plastic facing removed. Unfortunately, these panels are only available in boxes of 16 2'x4' panels for $100. Probably a bit steep for a single pair of small monitors, but I us quit a lot of it and the price is then not bad. ATS has single 1"x2'x4' panels for $7.50.

I think that the fiberglass panels clearly work better that cheap polyfill. No extrapolation to other materials. I do have the remains of a 16"x3" rockwool bat that I used to stuff a pair of subs.

Bob

Attachments

Have you tried grey open cell foam used for packing electronics or even the sound abatement foam? I manage to salvage that from stuff shipped to me so it is free. Works quite well when at least 1in thick.

Another option is the BASF sound abatement panels (BASOTECT) made of open cell reticulated melamine foam (https://www.youtube.com/watch?v=H6zHpjcsip0). This material is also sold as cleaning pads under the brand name of Mr Clean Magic Erase pads. May be less than your fiberglass panels and really absorbs sound well (I have experienced it in an industrial engine test cell), depending on how much coverage you need...

http://www.amazon.com/Mr-Clean-Eraser-Cleaning-8-Count/dp/B001339ZMW

Another option is the BASF sound abatement panels (BASOTECT) made of open cell reticulated melamine foam (https://www.youtube.com/watch?v=H6zHpjcsip0). This material is also sold as cleaning pads under the brand name of Mr Clean Magic Erase pads. May be less than your fiberglass panels and really absorbs sound well (I have experienced it in an industrial engine test cell), depending on how much coverage you need...

http://www.amazon.com/Mr-Clean-Eraser-Cleaning-8-Count/dp/B001339ZMW

Last edited:

Acoustic fiberglass for Hivac ducts etc. has always been good. Always will be. Ultratouch isn't too far off. Personally I've never had good results from open cell foam, but YMMV as ever.

Excellent test Bob. Thanks for sharing.

I spent countless hours experimenting with TL stuffing and lining back in the pre-MJK days, and remember getting similar results. Often times lining gave better results than stuffing, especially with lower Q drivers.

X, in my experimenting gray eggcrate foam always seems to rob dynamics and make the sound sort of listless and gray if used in the initial section around the driver. If the speakers are always played loud, it is very effective, but when turned down to low volumes, the sound goes to hell. It works fine for lining the rest of the line. On one occasion I ended up using acousta-stuff in the first 1/3 or so of a TL, and lining the rest with foam.

FWIW, I once compared Acousta-stuf to generic polyfill in a similar TL to your test mule (reverse taper 72" TL with driver at 1/5L). The Acousta-stuf was better performing by about 2 db in the midbass and lowbass, IIRC. The first null was also reduced. I am pretty sure this stuff is rebranded sleeping bag fill of some sort.

Good tip on the clean erase. I'll try that sometime.

I spent countless hours experimenting with TL stuffing and lining back in the pre-MJK days, and remember getting similar results. Often times lining gave better results than stuffing, especially with lower Q drivers.

X, in my experimenting gray eggcrate foam always seems to rob dynamics and make the sound sort of listless and gray if used in the initial section around the driver. If the speakers are always played loud, it is very effective, but when turned down to low volumes, the sound goes to hell. It works fine for lining the rest of the line. On one occasion I ended up using acousta-stuff in the first 1/3 or so of a TL, and lining the rest with foam.

FWIW, I once compared Acousta-stuf to generic polyfill in a similar TL to your test mule (reverse taper 72" TL with driver at 1/5L). The Acousta-stuf was better performing by about 2 db in the midbass and lowbass, IIRC. The first null was also reduced. I am pretty sure this stuff is rebranded sleeping bag fill of some sort.

Good tip on the clean erase. I'll try that sometime.

FWIW I used part of the contents of a "spiral" hollowfibre filled pillow to stuff my TABAQ. It was plumper than a normal pillow and filled the top 2/3 of the speaker very satisfactorily with 70g of material.

Sorry to drag up an old thread, but this seemed as good a place as any...

Trying to source some stuffing for a few MLTL builds that I am undertaking I came upon an acoustic insulation made from recycled cotton that is made right here in Logroño, where I reside!

GEOPANNEL INPAT 10 MM

GEOPANNEL SUPERPYL 40 MM

It looks similar to what they use to sell at CSS and what Dave (planet10) seems to prefer. It comes in rolls of 10mm thickness or in panels of 40mm or 50mm thickness. 40mm seems to thick but perhaps doubling up on the 10mm would be a good option.

Will this material work well or should I stick with Fiberglass or rockwool?

Trying to source some stuffing for a few MLTL builds that I am undertaking I came upon an acoustic insulation made from recycled cotton that is made right here in Logroño, where I reside!

GEOPANNEL INPAT 10 MM

GEOPANNEL SUPERPYL 40 MM

It looks similar to what they use to sell at CSS and what Dave (planet10) seems to prefer. It comes in rolls of 10mm thickness or in panels of 40mm or 50mm thickness. 40mm seems to thick but perhaps doubling up on the 10mm would be a good option.

Will this material work well or should I stick with Fiberglass or rockwool?

According to the spec., it will probably do. Since in most cases people seem to prefer a slightly under-damped result, I'd be inclined to go for the 10mm & double up if / as required which will give you a few more options.

+1, build big to allow for some tuning flexibility, then damp to 'taste', so add layers if required.

GM

GM

Thanks for the replies. I will go with the 10mm and may even get some fibreglass to do an subjective listening comparison (if I have the time and motivation of course).

Speaking of building big, is lining recommended for BIBs as well as MLTLs? If I remember correctly most suggestions were for stuffing.

Speaking of building big, is lining recommended for BIBs as well as MLTLs? If I remember correctly most suggestions were for stuffing.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Lining and Stuffing