[h=This is a Variac:]%2[/h]

It started acting up on me when I was testing out a power supply.

So, the first thing to do was unplug it and take it apart to find out

what was wrong with it.

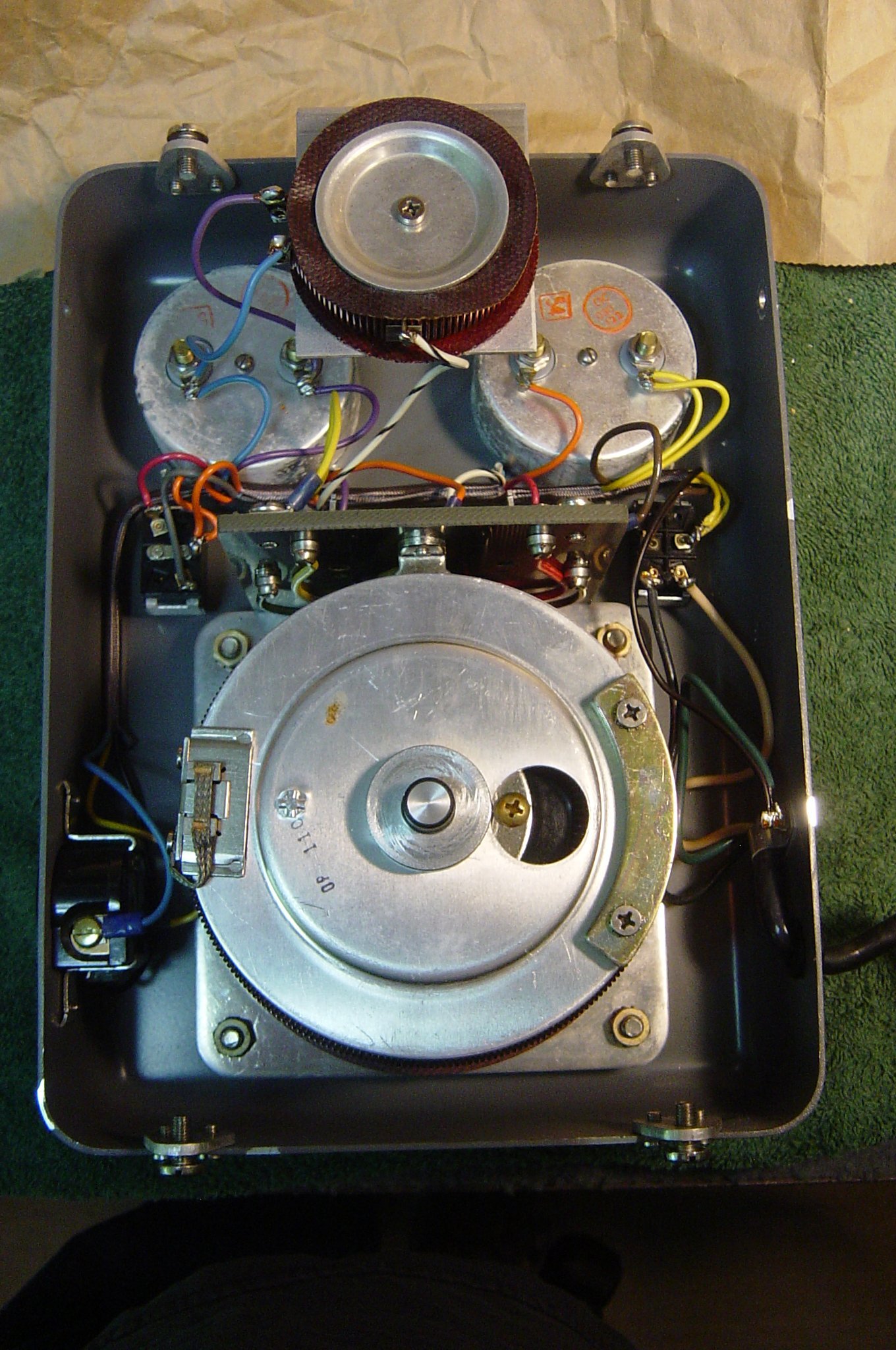

Shown here is the inside of the Variac. To open it up, remove

four large screws. Two at the top, two at the bottom. The black

arrows show where. Then carefully remove the back half of

the unit. The component parts are contained in the front

half of the case as shown:

Here is is and let's take a look inside and see if anything jumps out

at us. Close up inside view:

[h=Take Reference Pics & Notes]%2[/h]

Before taking it apart for further investigation, take some pics of the

instrument, draw diagrams of wiring in your work log. You do have

a work log, or lab log, or something to take notes as you go through

something right? If you don't, get one and start taking notes about

what you do.

There is nothing worse, then life happening in the middle of something

and when you return you forgot what you were doing. Even as a young

man, I did this, however as we get older, we tend to forget more and

more things. Also, it will help you work out other problems and come

up with solutions down the road.

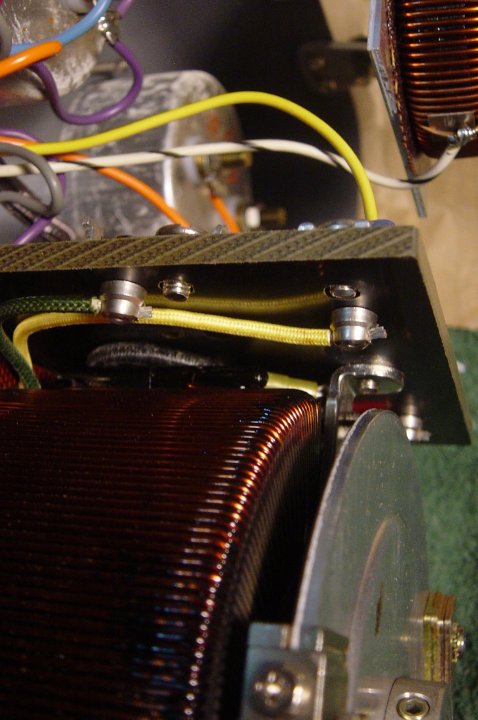

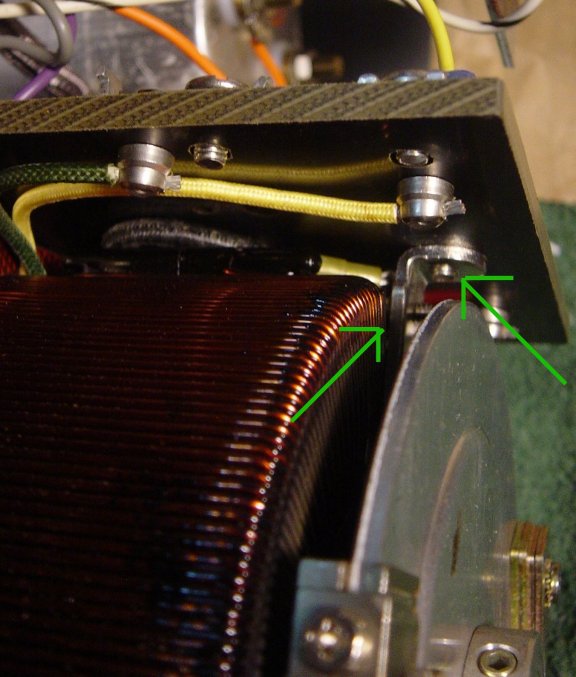

Here is the left half wiring:

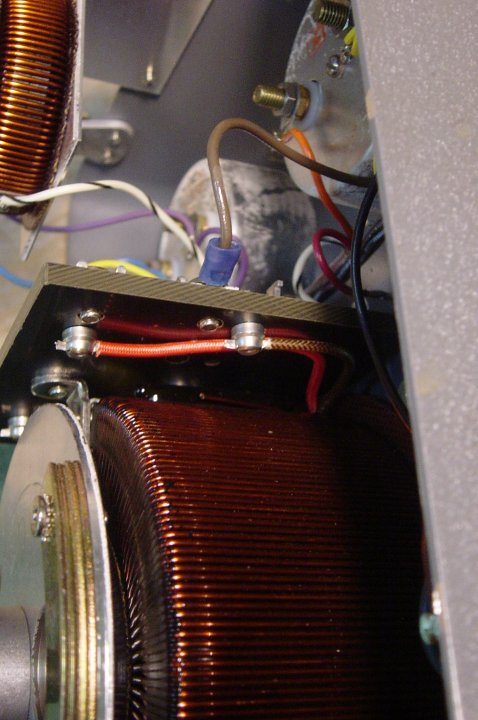

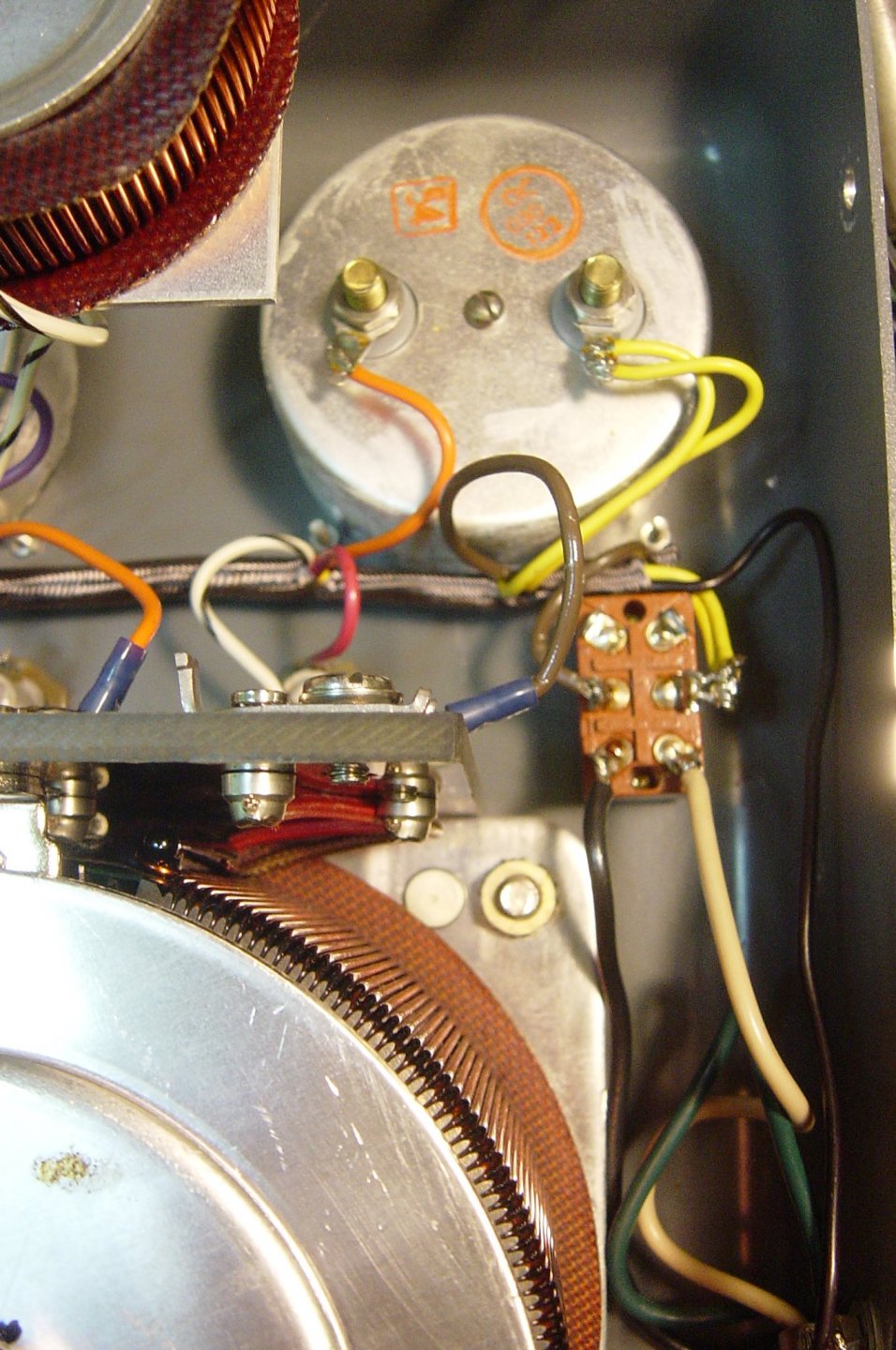

Here is the right half wiring:

[h=Disassembly of Brush From Track]%2[/h]

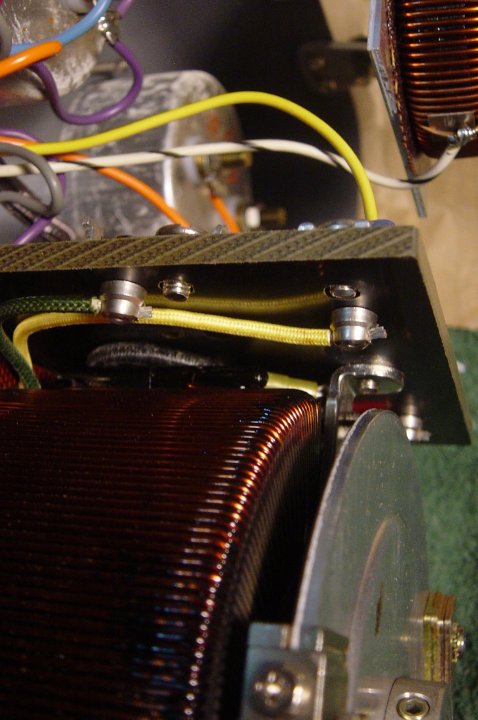

As long as we are in here, we should clean the track.

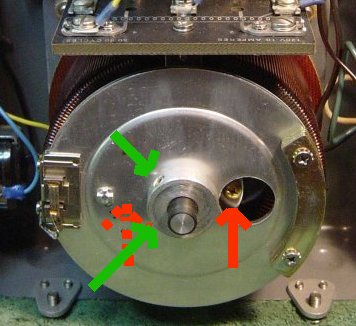

Note the location of the voltage knob and loosen the allen

head screws to free the center shaft (green arrows).

Then, there are two more screws under the brush holder

assembly. Red arrows, the solid arrow points to the visable screw

while the dotted arrow points to the hidden screw. Rotate the

brush wheel to reveal and remove the screw.

Now there is one more piece to remove, and this is the lead and

fixture for the start poing on the winding. Gently pull the knob

out of the front and then move the brush assembly to unsrew

it. There are two screws which the thin green arrow points too.

Here is a pic of the track after cleaning.

Clean it with a lint free cloth such at Kimwipes or Techwhipes.

it's 70% isopropal alcohol 30% water

OR

use 100% isopropal alcohol. Wipe from center to outside

along to track to get all the old carbon off it.

The part of the track along the upper right still has a

problem after cleaning it. It is noiser then earlier in the

turn cycle.

[h=Track Pic After Cleaning:]%2[/h]

[h=Problem Switch]%2[/h]

Check out the switch on the right, with the two yellow wires coming

from the meter. Doesn't look so good.

This should explain why I was having problems. This is the on/off

switch and as you can see the terminal was just floating. The rivit

was burned off. Shorted for a long time probably and filled with

carbon.

[h=

Here is the new switch installed.]%2[/h]

Put back together using the opposite order of disasembly.

It started acting up on me when I was testing out a power supply.

So, the first thing to do was unplug it and take it apart to find out

what was wrong with it.

Shown here is the inside of the Variac. To open it up, remove

four large screws. Two at the top, two at the bottom. The black

arrows show where. Then carefully remove the back half of

the unit. The component parts are contained in the front

half of the case as shown:

Here is is and let's take a look inside and see if anything jumps out

at us. Close up inside view:

[h=Take Reference Pics & Notes]%2[/h]

Before taking it apart for further investigation, take some pics of the

instrument, draw diagrams of wiring in your work log. You do have

a work log, or lab log, or something to take notes as you go through

something right? If you don't, get one and start taking notes about

what you do.

There is nothing worse, then life happening in the middle of something

and when you return you forgot what you were doing. Even as a young

man, I did this, however as we get older, we tend to forget more and

more things. Also, it will help you work out other problems and come

up with solutions down the road.

Here is the left half wiring:

Here is the right half wiring:

[h=Disassembly of Brush From Track]%2[/h]

As long as we are in here, we should clean the track.

Note the location of the voltage knob and loosen the allen

head screws to free the center shaft (green arrows).

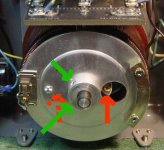

Then, there are two more screws under the brush holder

assembly. Red arrows, the solid arrow points to the visable screw

while the dotted arrow points to the hidden screw. Rotate the

brush wheel to reveal and remove the screw.

Now there is one more piece to remove, and this is the lead and

fixture for the start poing on the winding. Gently pull the knob

out of the front and then move the brush assembly to unsrew

it. There are two screws which the thin green arrow points too.

Here is a pic of the track after cleaning.

Clean it with a lint free cloth such at Kimwipes or Techwhipes.

it's 70% isopropal alcohol 30% water

OR

use 100% isopropal alcohol. Wipe from center to outside

along to track to get all the old carbon off it.

The part of the track along the upper right still has a

problem after cleaning it. It is noiser then earlier in the

turn cycle.

[h=Track Pic After Cleaning:]%2[/h]

[h=Problem Switch]%2[/h]

Check out the switch on the right, with the two yellow wires coming

from the meter. Doesn't look so good.

This should explain why I was having problems. This is the on/off

switch and as you can see the terminal was just floating. The rivit

was burned off. Shorted for a long time probably and filled with

carbon.

[h=

Here is the new switch installed.]%2[/h]

Put back together using the opposite order of disasembly.

Attachments

-

005.FrontVariac.jpg60.5 KB · Views: 704

005.FrontVariac.jpg60.5 KB · Views: 704 -

05.InsideVariac.jpg492.3 KB · Views: 694

05.InsideVariac.jpg492.3 KB · Views: 694 -

007.InsideVariac.jpg97.6 KB · Views: 574

007.InsideVariac.jpg97.6 KB · Views: 574 -

008.LeftBFWipeDown.jpg62.5 KB · Views: 513

008.LeftBFWipeDown.jpg62.5 KB · Views: 513 -

008.RtBFWipeDown.jpg64.8 KB · Views: 504

008.RtBFWipeDown.jpg64.8 KB · Views: 504 -

009.AFTWipeDown.jpg97.1 KB · Views: 498

009.AFTWipeDown.jpg97.1 KB · Views: 498 -

012.RtSwitchTab.jpg71.8 KB · Views: 661

012.RtSwitchTab.jpg71.8 KB · Views: 661 -

014.BrushAssyRemove.jpg30.4 KB · Views: 515

014.BrushAssyRemove.jpg30.4 KB · Views: 515 -

015.BrushAssyRemove.jpg66.5 KB · Views: 494

015.BrushAssyRemove.jpg66.5 KB · Views: 494 -

013.RtSwitchfix.jpg248.7 KB · Views: 482

013.RtSwitchfix.jpg248.7 KB · Views: 482

Last edited: