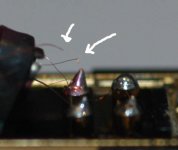

Most people won't recognize it btu this picture is an openen Audio Technica OC 9 moving coil cartridge.

As you might see the internal (very small) wiring has been overloaded and burned. So both channels are dead. You need a good magnifying glass to be able to see this. (Or a good Macro lens like I got)

So both channels are dead. You need a good magnifying glass to be able to see this. (Or a good Macro lens like I got)

Anyway, is there any change I could get this repaired at reasonable costs. The cartridge only has been playing maiximum 50-100 hours.

As you might see the internal (very small) wiring has been overloaded and burned.

So both channels are dead. You need a good magnifying glass to be able to see this. (Or a good Macro lens like I got)

So both channels are dead. You need a good magnifying glass to be able to see this. (Or a good Macro lens like I got) Anyway, is there any change I could get this repaired at reasonable costs. The cartridge only has been playing maiximum 50-100 hours.

Attachments

SY said:OK, I can't help it, I have to ask.... how did you do it?

I built the very nice and cheap VSPS (high gain) phono pre. I'm running it on 12V lead batteries, this all sounds very good for the price.

I recharged the batteries yesterday and hooked one of them with the wrong polarity.

I actually spend the entire evening building a new VSPS because I thougth this was the problem.

Taking shots of cartridge internals needs a good tripod and the lens to be stopped down to f/40. Even with bags of daylight, exposure tends to be counted in tens of seconds, and needs to be bracketed. Lighting is critical - I find holding 10" square of aluminium nearby during the exposure to be extremely useful for directing light where I want it and removing shadows.

You have nothing to lose in attempting a repair. You probably need to buy a jeweller's loupe or surgeon's magnifying glasses and a really small tip for your iron. Good luck.

You have nothing to lose in attempting a repair. You probably need to buy a jeweller's loupe or surgeon's magnifying glasses and a really small tip for your iron. Good luck.

I used to repair watches long time ago.

Some tips:

Listen to some classical music, stay very calm, heat the room at a comfortably level, close all doors, unhook the phone, clean the workspace and use a piece of nice new white paper to layout the tools you plan to use.

This, in combination with EC8010’s tips should do the trick.

Remember, you’re probably dealing with parts ten times smaller then the smallest SMD.

Good luck.

/Hugo

Some tips:

Listen to some classical music, stay very calm, heat the room at a comfortably level, close all doors, unhook the phone, clean the workspace and use a piece of nice new white paper to layout the tools you plan to use.

This, in combination with EC8010’s tips should do the trick.

Remember, you’re probably dealing with parts ten times smaller then the smallest SMD.

Good luck.

/Hugo

Attachments

Netlist said:Listen to some classical music, stay very calm, heat the room at a comfortably level, close all doors, unhook the phone, clean the workspace and use a piece of nice new white paper to layout the tools you plan to use.

Excellent tips! I shall use them myself...

Possible but no guarantees. Comment above regarding coils is a potential show stopper.

About thirty years ago I managed to solder some similar itty bitty wires on an Empire cartridge that had been mechanically damaged. I was very near-sighted then which was an advantage as I could press a sheet of paper right up to my nose and focus on it. Could see the hairs on all the little fibers. On the other hand I, literally couldn't focus on my own outstretched hand! I also had a much steadier hand back then (which is odd because in those days wine helped make things steadier - to a point). Anyway, the point is you need to be able to see what you are doing and hold thew solderting instrument dead steady - it is probably do-able.

Suggestion: don't try to apply the solder to both pieces held together at the same time. Tin each separately then bring them in contact and just touch the tip of the iron to them and remove.

About thirty years ago I managed to solder some similar itty bitty wires on an Empire cartridge that had been mechanically damaged. I was very near-sighted then which was an advantage as I could press a sheet of paper right up to my nose and focus on it. Could see the hairs on all the little fibers. On the other hand I, literally couldn't focus on my own outstretched hand! I also had a much steadier hand back then (which is odd because in those days wine helped make things steadier - to a point). Anyway, the point is you need to be able to see what you are doing and hold thew solderting instrument dead steady - it is probably do-able.

Suggestion: don't try to apply the solder to both pieces held together at the same time. Tin each separately then bring them in contact and just touch the tip of the iron to them and remove.

EC8010 said:You have nothing to lose in attempting a repair. You probably need to buy a jeweller's loupe or surgeon's magnifying glasses and a really small tip for your iron. Good luck.

A small tip? ... A needle is to thick! But you're right I got nothing to loose.

Netlist said:I used to repair watches long time ago.

Some tips:

Listen to some classical music, stay very calm, heat the room at a comfortably level, close all doors, unhook the phone, clean the workspace and use a piece of nice new white paper to layout the tools you plan to use.

This, in combination with EC8010’s tips should do the trick.

Remember, you’re probably dealing with parts ten times smaller then the smallest SMD.

/Hugo

And I have difficulties handling SMD

, altough until now all SMD repairs I attemted were succesfull.

, altough until now all SMD repairs I attemted were succesfull.Here is the best picture I could take in one shot, still some depth of field limitation. As you see only two of the four coil wires have been damaged. I'm wondering what tipe of wire to use for this repair. (I might be cheaper of just trading the cartridge fo a new one.)

Attachments

If you use some reasonably fine wire and wrap it round the pins to make a mechanical joint, it ought to be possible to solder that end then ease the other into postion so that the two wires touch naturally. Then with your steadiest hand and 1mm 700F tip on your iron, plus some of that really fine solder intended for surface mount, it shouldn't be too difficult. Use Blutak (or whatever) to lock the cartridge down solidly, or hold it in a vice. Rest your little fingers on the vice to steady your hands as you bring the iron and solder into conjunction with the joint.

This is the diyAudio forum - we don't give up - we fix it!

This is the diyAudio forum - we don't give up - we fix it!

Yes....No

So I soldered the other channel also. Unfortunately there were 2 wires loose on the other channel, so I'm not sure if the phase is right.

Both channels now measure resistance around 3 to 4 ohms. I hope this is ok. Next thing is to test if it plays some music.

So I take the short installation route.... a simple visual HTA aligment, nust to check if there is sound coming out of the cart.

Unfortunately only the left channel (the one with one broke wire)

plays sound, and sound is all that it is bacuse it is really distorted and very low volume.

I guess the coils were damaged all the way through

So I soldered the other channel also. Unfortunately there were 2 wires loose on the other channel, so I'm not sure if the phase is right.

Both channels now measure resistance around 3 to 4 ohms. I hope this is ok. Next thing is to test if it plays some music.

So I take the short installation route.... a simple visual HTA aligment, nust to check if there is sound coming out of the cart.

Unfortunately only the left channel (the one with one broke wire)

plays sound, and sound is all that it is bacuse it is really distorted and very low volume.

I guess the coils were damaged all the way through

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Can this be repaired??