Good evening DIY-audio,

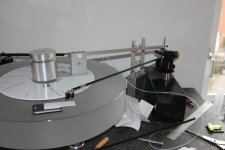

Time to show my latest project: my 17" tonearm (440 mm to be exact).

Last year i scored a very nice Scheu platter with a 50 cm diameter. This is a serious piece of hardware.....it rotates so stable it is frightening. When in motion it takes 5 minutes to stop (when the thread is removed). But there is a problem: there are almost no commercial available tonearms for this item. I do use the Scheu Classic; but it barely fits. A Nottingham 12" and a VPI didn't fit either....time for a new project.

From the start the idea was to make a serious long arm; as long as the Feickert Protractor would allow (= 440 mm). So we're talking more than 17". I fiddled with Schroeder-style and unipivots; but at those lengths they seem to be serious nervous. Tangential arms were discarded as i did not want aircompressors in my room. Cardanic suspension could work IF i had the availability of a full-blown mechanical workspace...and i haven't (and the knowledge of course). So i decide to go along with the WTA-principle. The Well Tempered Arm is still in production (in various forms). Basically it is a 2-string suspension. But with a very nice twist as the 2 strings are adjustable in space between them. That distance is also a measure for the anti-skating !

Besides the quite stable suspension the tonearm itself is not directly coupled to the strings but the complete assembly floats in a siliconebath; it dampens any resonance-residue.

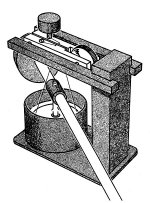

See the WTA as a seesaw: moving front and back is quite easy (but now dampened by the silicone). Twisting is almost impossible....the seesaw has the inherent drive to turn back to the original state: hey presto....the anti skating. I'll add a sketch from the internet; it'll explain the working-principle.

The arm itself is a great find: an arrow-shaft. Very straigth, light, tough and internally damped as well. I did some tests with the available arrows and found out that full-carbon dampened the best....but was not as stiff as aluminium. Aluminium had the highest specifications (serious low tolerance on straigthness)...but had a nasty resonance. This is what WTA itself uses. They fill their armtubes with sand......

The combination (aluminium tube shrouded with a carbon outershell) was perfect ! I made the proper holes in it for the 2 teflon tubes (one for each channel pair of innercables). Some archers gave me some usefull advise how to stop the rest-reonance. These archers fill even those combination-arrows with the most strange material. But definately not sand as this is uneven and has a tendency to move. Yes it will damp resonance; but it can cause trouble besides being very heavy. I took their advise and put it to use in my arm.

The total armtube, teflon tubes, cabling, filling, headshell and dampening weighs....15 gramms....for a 17" tonearm (and even more so now the back of the tonearm after the pivital point is included as wel). Quite light !

The counterweigth is from an old Decca tonearm. The original WTA's are simple a slab of stainless steel with a hole in the middle. I like to have the weith more low; below the tonearm itself. A well-respected member of this forum, EC8010, reminded at another thread not to put the weigth too close at the pivotal point. Yes, this is nice for ease-of-rotation. But it will be a serious load for the suspension itself for the counterweigth will be heavier and heavier. For practical reasons i took the available distance to the back-wall.

After modifications to an old WTA (making the siliconbath adjustable) and finding a proper armbase (7 kgs of hardstone) the most difficult task was the cabling. Of course there is just a single cable from cartridge-clip to RCA (at the preamplifier). The first 44 cm are in the tonearm, the next 15 cm are in a standard/cable-feed (so that the cables do not hinder the tonearm in rotation) and then more than a meter to the preamplifier. With 0,13 mm diameter wire !

But it was well worth the effort. It sounds marvelous. Till now my Shelter 501MkII never presented the music that good.

The Scheu Classic with (modified) Denon DL-103 is still available.....but the tonearm at work....is the self build one !

Regards,

Reinout

Time to show my latest project: my 17" tonearm (440 mm to be exact).

Last year i scored a very nice Scheu platter with a 50 cm diameter. This is a serious piece of hardware.....it rotates so stable it is frightening. When in motion it takes 5 minutes to stop (when the thread is removed). But there is a problem: there are almost no commercial available tonearms for this item. I do use the Scheu Classic; but it barely fits. A Nottingham 12" and a VPI didn't fit either....time for a new project.

From the start the idea was to make a serious long arm; as long as the Feickert Protractor would allow (= 440 mm). So we're talking more than 17". I fiddled with Schroeder-style and unipivots; but at those lengths they seem to be serious nervous. Tangential arms were discarded as i did not want aircompressors in my room. Cardanic suspension could work IF i had the availability of a full-blown mechanical workspace...and i haven't (and the knowledge of course). So i decide to go along with the WTA-principle. The Well Tempered Arm is still in production (in various forms). Basically it is a 2-string suspension. But with a very nice twist as the 2 strings are adjustable in space between them. That distance is also a measure for the anti-skating !

Besides the quite stable suspension the tonearm itself is not directly coupled to the strings but the complete assembly floats in a siliconebath; it dampens any resonance-residue.

See the WTA as a seesaw: moving front and back is quite easy (but now dampened by the silicone). Twisting is almost impossible....the seesaw has the inherent drive to turn back to the original state: hey presto....the anti skating. I'll add a sketch from the internet; it'll explain the working-principle.

The arm itself is a great find: an arrow-shaft. Very straigth, light, tough and internally damped as well. I did some tests with the available arrows and found out that full-carbon dampened the best....but was not as stiff as aluminium. Aluminium had the highest specifications (serious low tolerance on straigthness)...but had a nasty resonance. This is what WTA itself uses. They fill their armtubes with sand......

The combination (aluminium tube shrouded with a carbon outershell) was perfect ! I made the proper holes in it for the 2 teflon tubes (one for each channel pair of innercables). Some archers gave me some usefull advise how to stop the rest-reonance. These archers fill even those combination-arrows with the most strange material. But definately not sand as this is uneven and has a tendency to move. Yes it will damp resonance; but it can cause trouble besides being very heavy. I took their advise and put it to use in my arm.

The total armtube, teflon tubes, cabling, filling, headshell and dampening weighs....15 gramms....for a 17" tonearm (and even more so now the back of the tonearm after the pivital point is included as wel). Quite light !

The counterweigth is from an old Decca tonearm. The original WTA's are simple a slab of stainless steel with a hole in the middle. I like to have the weith more low; below the tonearm itself. A well-respected member of this forum, EC8010, reminded at another thread not to put the weigth too close at the pivotal point. Yes, this is nice for ease-of-rotation. But it will be a serious load for the suspension itself for the counterweigth will be heavier and heavier. For practical reasons i took the available distance to the back-wall.

After modifications to an old WTA (making the siliconbath adjustable) and finding a proper armbase (7 kgs of hardstone) the most difficult task was the cabling. Of course there is just a single cable from cartridge-clip to RCA (at the preamplifier). The first 44 cm are in the tonearm, the next 15 cm are in a standard/cable-feed (so that the cables do not hinder the tonearm in rotation) and then more than a meter to the preamplifier. With 0,13 mm diameter wire !

But it was well worth the effort. It sounds marvelous. Till now my Shelter 501MkII never presented the music that good.

The Scheu Classic with (modified) Denon DL-103 is still available.....but the tonearm at work....is the self build one !

Regards,

Reinout

Attachments

-

WTA sketch.jpg87.3 KB · Views: 674

WTA sketch.jpg87.3 KB · Views: 674 -

IMG_8253.JPG60.3 KB · Views: 650

IMG_8253.JPG60.3 KB · Views: 650 -

IMG_8240.JPG82.9 KB · Views: 634

IMG_8240.JPG82.9 KB · Views: 634 -

IMG_8236.JPG99.4 KB · Views: 632

IMG_8236.JPG99.4 KB · Views: 632 -

IMG_8248.JPG51.9 KB · Views: 642

IMG_8248.JPG51.9 KB · Views: 642 -

IMG_8821.JPG70.8 KB · Views: 492

IMG_8821.JPG70.8 KB · Views: 492 -

IMG_8901.JPG101.3 KB · Views: 413

IMG_8901.JPG101.3 KB · Views: 413 -

IMG_8907.JPG76.2 KB · Views: 426

IMG_8907.JPG76.2 KB · Views: 426 -

IMG_8883.JPG57.1 KB · Views: 461

IMG_8883.JPG57.1 KB · Views: 461

Hi Reinout,

That's a beautiful setup, and some truly incredible workmanship on the arm! I'm curious as to how you find the general use of an arm that length? Is it easy to cue up, and use on a regular basis? Once you're off the arm clip, I would imagine that it just kinda floats about... is it still user friendly?

Congrats on a job well done!

Owen

That's a beautiful setup, and some truly incredible workmanship on the arm! I'm curious as to how you find the general use of an arm that length? Is it easy to cue up, and use on a regular basis? Once you're off the arm clip, I would imagine that it just kinda floats about... is it still user friendly?

Congrats on a job well done!

Owen

reply

To all; thanks for the compliments.

Tom: the poweramplifiers started as 833-amps. But as soon i had found out the TB 3/1000 i quickly changed to that power triode. These TB 3/1000 are far better constructed. Soundwise too they are nicer. Problem: find those triodes ! While 833's are even produced today the TB 3/1000 (or other members of that particular Philips tube family) stopped being produced in the early 70's.

(included a picture of the TB 3/1000 close up; i made also a thread on these amplifiers)

Owen: handling the arm isn't that big of a problem. Just use common sense. With any arm i do want OR a good armlift OR an fingerlift + armrest. A i did not have clue where this project would end i did not opt for the armlift. For otherwise i had to make an heigth adjustable armlift. So i took the armrest + fingerlift option. The silicone-bath dampens the complete arm-contraption quite good so it is really not too nervous.

But your right: do not drink (too much) and then try to get the cartridge on the vinyl.....end-of-cartridge !

(included a picture from the front view; from here it doesn't seem that long)

Regards,

Reinout

To all; thanks for the compliments.

Tom: the poweramplifiers started as 833-amps. But as soon i had found out the TB 3/1000 i quickly changed to that power triode. These TB 3/1000 are far better constructed. Soundwise too they are nicer. Problem: find those triodes ! While 833's are even produced today the TB 3/1000 (or other members of that particular Philips tube family) stopped being produced in the early 70's.

(included a picture of the TB 3/1000 close up; i made also a thread on these amplifiers)

Owen: handling the arm isn't that big of a problem. Just use common sense. With any arm i do want OR a good armlift OR an fingerlift + armrest. A i did not have clue where this project would end i did not opt for the armlift. For otherwise i had to make an heigth adjustable armlift. So i took the armrest + fingerlift option. The silicone-bath dampens the complete arm-contraption quite good so it is really not too nervous.

But your right: do not drink (too much) and then try to get the cartridge on the vinyl.....end-of-cartridge !

(included a picture from the front view; from here it doesn't seem that long)

Regards,

Reinout

Attachments

QUOTE: "These archers fill even those combination-arrows with the most strange material. But definately not sand as this is uneven and has a tendency to move. Yes it will damp resonance; but it can cause trouble besides being very heavy. I took their advise and put it to use in my arm." END QUOTE.

Reinout: ok you got me, I spent too much time looking for damping techniques for arrows without coming up with much. So tell us how do you damp an arm as long as yours and still manage to keep the mass low? Thanks.

Reinout: ok you got me, I spent too much time looking for damping techniques for arrows without coming up with much. So tell us how do you damp an arm as long as yours and still manage to keep the mass low? Thanks.

Awesome looking set up. That TT and arm makes my efforts look puny (and amateurish compared to yours).. 😀

filling

Good evening Moray James,

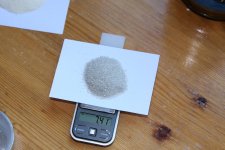

please don't laugh....it is NOT a joke. I got this tip from some competition-archers. They fill their arrows with coffeecreamer. It dampens a lot and is not that shocking heavy.

So that is what i did as well.

First took out the sand from an original WTA (7,41 grams). The same volume of coffeecreamer weighs.....3,76 grams. So half ! And more important: it works. Even with this serious oversized but featherligth armtube and fairly low compliance cartridge the arm/cartridge resonance test gave me a solid 14 Hz resonance.

This answers your question ?

Regards, Reinout

Good evening Moray James,

please don't laugh....it is NOT a joke. I got this tip from some competition-archers. They fill their arrows with coffeecreamer. It dampens a lot and is not that shocking heavy.

So that is what i did as well.

First took out the sand from an original WTA (7,41 grams). The same volume of coffeecreamer weighs.....3,76 grams. So half ! And more important: it works. Even with this serious oversized but featherligth armtube and fairly low compliance cartridge the arm/cartridge resonance test gave me a solid 14 Hz resonance.

This answers your question ?

Regards, Reinout

Attachments

Reinout: yes indeed that is interesting. Here is another material which is also very interesting and might even be lighter, Perlite. Perlite is a stone material which can be popped like rice or corn into an expanded form. The result is like a super light version of puffed rice all full of air holes it looks like a sponge. Perlite is used in agriculture as an admix to soil as it holds many times its weight in water. I have used Perlite as a damping material in loudspeakers (KEF did this with activated charcoal) and it is the most effective damping material (for this application) that I have encountered. When you open a small bag of Perlite you will find that the particles range from the size of puffed rice to powder. You could sift it for the particle size that you wanted and try that. I think that with any such material you would want to oven dry it prior to install and seal the tube so moisture could not be drawn in and change your arm mass over time. Thanks for sharing this interesting aspect of your design.

PS: coffee creamer powder can also be used to generate some fine pyrotechnics as the powder can be ignited easily and will put on a cheap show on a dark night.

PS: coffee creamer powder can also be used to generate some fine pyrotechnics as the powder can be ignited easily and will put on a cheap show on a dark night.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- 50 cm turntable + 17" tonearm (WTA-based)