How would you go about making your own Tonearm damping trough, with the little paddle that hangs off the rear of the arm, and slowly moves through the silicone in the trough as the record plays. I'm wondering if anybody tried this with say the ever popular Rega RB-300 for instance. (Or any arm) Even if you haven't, you might have thought about it, and may have some ideas. Denon had done this electronically with their, "Servotracer" tonearm.

This is completely subjective on my part, but I picture the cantilever/stylus as being like the springs on your car with no shock absorbers. It seems to me like it would be better on almost any arm, but on the other hand, hardly any company is doing this at the moment. Hmmm

Questions: What vintage tonearms have this? I can hardly find any. How big should the paddle be, and should it be made to be more effective in the vertical plane, than in the horizontal plane?

This is completely subjective on my part, but I picture the cantilever/stylus as being like the springs on your car with no shock absorbers. It seems to me like it would be better on almost any arm, but on the other hand, hardly any company is doing this at the moment. Hmmm

Questions: What vintage tonearms have this? I can hardly find any. How big should the paddle be, and should it be made to be more effective in the vertical plane, than in the horizontal plane?

DaveThreshold said:

This is completely subjective on my part, but I picture the cantilever/stylus as being like the springs on your car with no shock absorbers.

Cartridges have damping. Some more than others.

The reason for matching arm-mass and cartridge compliance is that the arm itself 'mass damps' the movement of the combined arm/cartridge - the heavier the arm, the more mass-damping.

Hence, too light an arm will not effectively damp a low-compliance (usually MC) cartridge and will result in a tendency for the arm/cart. assembly to 'resonate' (I've always preferred to call it 'oscillate') at freq. above, say, 16HZ, and well into the audio band, at least from the system's POV, hence the optional viscous damper on such low-to-medium mass arms as old SME 3009's.

The townshend system works well, much better than a trough at the arm pivot because it provides a more progressive (or less linear) rate of LF damping..

Hence, too light an arm will not effectively damp a low-compliance (usually MC) cartridge and will result in a tendency for the arm/cart. assembly to 'resonate' (I've always preferred to call it 'oscillate') at freq. above, say, 16HZ, and well into the audio band, at least from the system's POV, hence the optional viscous damper on such low-to-medium mass arms as old SME 3009's.

The townshend system works well, much better than a trough at the arm pivot because it provides a more progressive (or less linear) rate of LF damping..

The best place to apply viscous damping is at the headshell, so the Townsend method is ideal. Next best is near the bearing. Unipivots almost always needs damping and most designs use far too much. I use STP engine oil modifier on my unipivots and use the minimum I can get away with.

The effective mass of the arm and the mass of the cartridge bounces on the compliance of the cartridge suspension, and some cartridges have some damping. Most don't damp the resonance correctly, and that's why SME introduced their FD200 fluid damper. Coincidentally, it also helped when the resonant frequency was wrong (should be 10-12Hz).

The effective mass of the arm and the mass of the cartridge bounces on the compliance of the cartridge suspension, and some cartridges have some damping. Most don't damp the resonance correctly, and that's why SME introduced their FD200 fluid damper. Coincidentally, it also helped when the resonant frequency was wrong (should be 10-12Hz).

Here is some food for thought for everybody! So I found a Townshend TT on Ebay, and I sent him a message asking for the dimensions of the outrigger setup. I'm thinking of doing one myself, when I get my new Technics SL1210MK5G. It comes with OFC wiring. I'll also do a couple of KAB mods. Anyway, here is the response by Noel Sidebottom:

DAVE: Thanks for your enquiry

The trough is 10mm wide and 10 mm deep. The paddle is 3.125mm diameter and the wall thickness is .4mm. The paddle is immersed 8mm into the fluid and the fluid viscosity is 12,500 CS. These parameters were chosen to give critical damping between 8Hz and 12Hz with a typical low to medium mass arm and cartridge with a low to mid compliance. For further info, see

http://www.townshendaudio..net/index.php?option=com_content&task=view&id=65&Itemid=137

Please remember that the total cost for the unit if the arm and trough are added is £1780 .

Thanks

Townshend Audio.

DAVE: Thanks for your enquiry

The trough is 10mm wide and 10 mm deep. The paddle is 3.125mm diameter and the wall thickness is .4mm. The paddle is immersed 8mm into the fluid and the fluid viscosity is 12,500 CS. These parameters were chosen to give critical damping between 8Hz and 12Hz with a typical low to medium mass arm and cartridge with a low to mid compliance. For further info, see

http://www.townshendaudio..net/index.php?option=com_content&task=view&id=65&Itemid=137

Please remember that the total cost for the unit if the arm and trough are added is £1780 .

Thanks

Townshend Audio.

I had the same question (RB 250) until I bought from Rega RB 250 / 300 DAMPING THROUGH KIT | eBay

Had positive results in the sound after some tests, i will come back with a detailed presentation

Had positive results in the sound after some tests, i will come back with a detailed presentation

In an arm that is not totally inert viscous damping improves the situation.

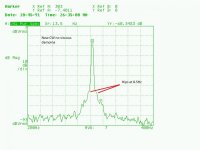

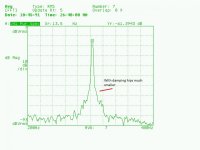

Here are plots of 300Hz tone with and without damping on my EPA-100. Even though the visual improvement is small the sonic improvement was clearly audible.

I also found adding too much damping made the sidebands worse than no damping. My viscous damping is adjustable, an M3 bolt into the trough can be adjusted for more or less damping.

Here are plots of 300Hz tone with and without damping on my EPA-100. Even though the visual improvement is small the sonic improvement was clearly audible.

I also found adding too much damping made the sidebands worse than no damping. My viscous damping is adjustable, an M3 bolt into the trough can be adjusted for more or less damping.

Attachments

- Home

- Source & Line

- Analogue Source

- Tonearm Tracking Damper?